The Definition of RFID Systems

RFID stands for "Radio Frequency Identification" and refers to a technology that enables the contactless and automated exchange of information using electromagnetic radio waves. RFID technology makes it possible to uniquely identify objects, animals, or people using small electronic devices known as RFID tags or transponders. An RFID system consists of integrated circuits (RFID chips). These tiny electronic circuits are equipped with antennas. An RFID chip is the heart of an RFID transponder, RFID label, or RFID sensor.

Each RFID transponder has at least one unique identification number. RFID readers or RFID read/write devices can be used to store and read information on the chip. RFID systems form the basis for the digitalization of companies and the Internet of Things (IoT).

RFID – How Does RFID Technology Work?

RFID technology is based on electromagnetic radio waves. RFID systems consist of various components. In simple terms, these are a transmitter and a receiver unit.

Specifically, in most cases, an RFID system consists of passive RFID transponders (also known as passive RFID tags or RFID labels), which do not have their own power supply in the form of a battery. The second component is the RFID read/write device. The RFID reader (wireless RFID reader) generates an electromagnetic field by emitting radio waves via its antenna.

If the passive RFID transponder is in the vicinity of this electromagnetic field, the field induces a current in the transponder's antenna. This current supplies the transponder with energy. The transponder is activated by this energy and can respond to requests from the RFID reader. This simple RFID functionality is based on the resonance principle and contactless magnetic (inductive) coupling.

The coupling enables the RFID tag to send the data stored in the transponder to the reader, or to receive and store new data on request from the reader. The stronger the electromagnetic field, the greater the reading range between the RFID transponder and the RFID reader.

An RFID reader can only receive data from an RFID tag. Data is exchanged in one direction. This RFID system is usually used when the RFID tag should only transmit the unique identifier (ID) of the object – for unique identification or traceability, for example.

An RFID read/write device also has the option of sending information back to the transponder and writing information to it. This is useful in applications where the data on the RFID tags needs to be updated. This could be product information, for example.

The read range of RFID systems depends on various factors. This includes, in particular, the type of RFID tag (active or passive), the frequency at which the system operates, and the transmission power of the reader. As the reading range is of great importance for the RFID application, the various RFID systems (passive or active) and the available frequency bands are explained in more detail below. The precise selection of RFID products enables the RFID range to be increased.

In addition to the hardware, the RFID system also includes middleware (software). The middleware or RFID server filters and analyzes the information, and integrates it into other systems such as warehouse management software or ERP systems.

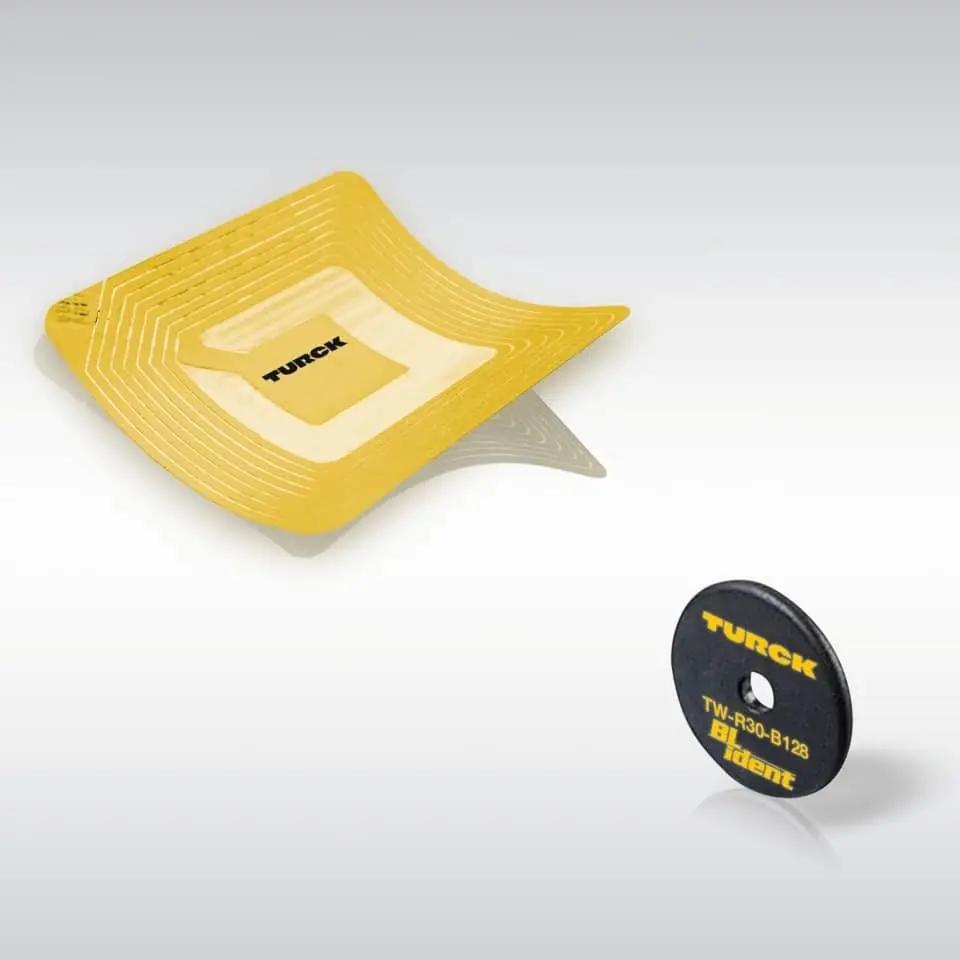

How is an RFID Tag Constructed?

An RFID inlay is the basic component of every RFID tag or transponder. The inlay consists of two components: The RFID chip and the antenna. The inlay can also be supplemented with sensors. Temperature, humidity, motion, or light sensors can be integrated, for example. Some tags have an additional memory for user-defined data or for logging purposes. This memory can be write-protected or writable. To ensure the security of the RFID system in security-relevant applications, RFID tags can contain cryptographic modules to encrypt and protect the data. Active RFID tags contain batteries or other energy sources that increase the range and functionality of the tag.

In addition to these core components, an RFID inlay is attached to a carrier material (usually a flexible plastic film) that gives the inlay a certain structure and protection

RFID inlays are often integrated into labels, stickers, or robust, weatherproof tags. If the RFID tag is to be used in a harsh environment, it can be installed in a robust housing. The housing provides physical protection against environmental influences or mechanical damage, especially in industrial applications.

Overall, Ultra High Frequency Radio Frequency Identification (UHF RFID) is most commonly used for wireless communication in the Industrial Internet of Things (IIoT), as it offers higher data transmission rates, and an efficient balance between range and signal quality. One advantage is that the RFID tags can be read simultaneously from a great distance and in large quantities. Which frequency bands are associated with which properties is explained in a section below.

Facts & Figures

According to a report by the American market research and consulting company "Global Market Insights", applications such as retail, healthcare, industry, government, and financial services are contributing to the growth of the RFID market. The Indian market research and consulting company "Mordor Intelligence" expects the RFID market to grow by almost 12 percent by 2029. The use of RFID in retail, for example, is expected to increase at an average growth rate of over 12.2 percent between 2024 and 2032. By component, the RFID market is made up of tags, antennas, readers, and middleware. RFID tags had a market share of over 40 percent in 2023.

RFID Products and Components

What Kinds of Different RFID Systems Are There?

The difference between a passive and an active RFID system lies mainly in the energy supply and the resulting application possibilities. Here are the most important differences and application areas:

Passive RFID Systems

Passive RFID tags do not have their own power supply. They draw their energy from the electromagnetic field of the reader. They therefore only emit signals when they are detected. The reading range is usually between a few centimeters and several meters, depending on the frequency and the size of the antenna. Compared to active transponders, passive tags are less expensive and more frequently used.

Application Areas for Passive RFID Systems: Goods tracking in retail | Inventory | Access control | Contactless access cards | Libraries and rental systems | Tracking of goods or parcels over short distances

Active RFID Systems

Active RFID tags have their own energy source. This is usually a battery. The battery enables them to emit stronger signals. They are not solely dependent on the electromagnetic field of the RFID reader. The reading range can be up to 100 meters or more, as the tags emit their own signal. Active RFID tags are more expensive than passive tags as they contain a battery and additional electronics.

Application Areas for Active RFID Systems: Tracking containers or goods over long distances | IoT asset management | Monitoring important or expensive equipment and facilities | Tracking people | Work safety and emergency monitoring in hazardous working environments | Tolling systems

Semi-Active RFID Systems

A third form of RFID system uses semi-active transponders. These transponders combine the properties of passive and active RFID tags. They are essentially battery-powered passive RFID tags.

Semi-active transponders have their own battery, which supplies the internal chip and possibly other components such as sensors with power. Unlike active tags, however, the battery is not used to send signals to the reader. Instead, they use the electromagnetic field emitted by the reader for communication.

The range is often greater than that of passive tags, as the chip and sensors are always operational and the signal can be better recognized. However, the range is shorter than with active tags. One advantage of semi-active tags is their longer service life compared to active tags, as the battery is only used to operate the chip and sensors.

Application Areas for Semi-Active Transponders: Temperature monitoring | Use cases with heat resistance | Cold chains and medication transportation | Inventory | Motion detection | Monitoring environmental conditions

Low Frequency (LF) for Robustness and Material Penetration

Low Frequency (LF) refers to a frequency band in RFID technology that is typically around 125 kHz to 134 kHz. The range of LF RFID systems is shorter compared to higher frequencies, and is usually between a few centimeters and a maximum of one meter. The lower frequency allows for better a penetration of non-metallic materials.

This enables LF tags to work well in environments with high humidity, dust, or other non-metallic obstacles. LF RFID tags can also be attached to metallic tools. LF RFID's ruggedness and material penetration make it suitable for applications where reliability and low interference are critical, even when range is limited. The data transmission rate is lower than with RFID systems based on higher frequencies.

Application Areas for LF RFID Systems: Animal identification | Access control | For immobilizers or starting cars | Managing tools or machines in workshops | Tracking patients or medical devices | Authentication solutions | Maintenance

The HF Frequency Range is Used Worldwide

High Frequency (HF) is a frequency range in RFID technology that is usually at 13.56 MHz. The range of HF RFID is between a few centimeters and a maximum of one meter, depending on the antenna size and environmental conditions. The data transmission rate is higher than with LF systems, which enables faster communication.

In terms of interference, HF systems are less susceptible to interference from non-metallic materials, but can be more influenced by metal and water. The RF frequency range is used worldwide and is highly standardized. The ISO/IEC 15693 (smart labels) and ISO/IEC 14443 (contactless smart cards) are two important standards.

Application Areas of HF RFID: Contactless credit cards and payment systems such as Near Field Communication (NFC) often use HF RFID | Inventory of books | Access control systems | Tickets | Inventory management | Asset management | Tool tracking | Document tracking | Passports and ID cards | Textile management

Ultra High Frequency (UHF) Has a Reading Range of up to 12 Meters

Ultra High Frequency (UHF) RFID systems operate in the frequency range from 860 to 960 MHz. Depending on the reader and the environment, the range can extend from a few meters to 12 or more meters. The range is therefore much longer, compared to HF or LF technology. The data transmission rate of UHF RFID is also higher than HF and LF RFID, which enables fast communication and efficient data transmission.

Due to the higher frequency, UHF RFID is more susceptible to interference from metal and liquids. However, special tag designs and reader configurations can improve performance. UHF RFID is internationally standardized by standards such as EPC Gen 2 (ISO 18000-6C) and is used worldwide.

Application Areas for UHF RFID: Inventory management | Traceability | Asset Tracking | Vehicle identification | Toll collection | Supply chain management | Anti-theft Protection | Event management | Production tracking | Quality assurance | Predictive maintenance | Condition monitoring | Digitalization in the supply chain

RFID Solution in Use at Rosenbauer

The Rosenbauer Group has implemented an RFID zero-defect solution for the automated replenishment of c-parts. Part of the replenishment system are over 15,000 RFID-tagged KLT boxes. These are used for storing the c-parts and for transporting them between the c-parts warehouse and the production facility. An average of 200 boxes can be captured simultaneously as tugger trains pass through the RFID gates at the production sites. Kathrein Solutions RFID readers, antennas, and CrossTalk platform were used.

The Rosenbauer Group has implemented an RFID zero-defect solution for the automated replenishment of c-parts. Part of the replenishment system are over 15,000 RFID-tagged KLT boxes. These are used for storing the c-parts and for transporting them between the c-parts warehouse and the production facility. An average of 200 boxes can be captured simultaneously as tugger trains pass through the RFID gates at the production sites. Kathrein Solutions RFID readers, antennas, and CrossTalk platform were used.

Today, we no longer have unwanted production breaks due to missing C-parts. The boxes deliver reliably, fully, and just-in-time. The zero-defect solution has also given us a read accuracy of near 99 %.

Manuel Schwarzbauer

Head of Logistics Plant 1

EMBL Identifies Samples with RFID

Over 200,000 crystalline samples are processed by the European Molecular Biology Laboratory (EMBL) per year. These samples are stored at close to -200°C. Robots automate the handling of the samples. During test series, a customized, cryo-resistant HF RFID tag from HID is used to enable the continuous identification of each sample. Robots identify individual samples that are stored in pucks in order to insert or remove them from an analyzer.

In the test series with more than 200,000 samples per year, RFID technology is essential for efficient and correct handling. The transponders withstand the extreme conditions such as cryogenic temperatures and high temperature fluctuations.

Richard Aufreiter

VP Product Marketing

Battery Manufacturer Uses HF and UHF RFID

Environmental data, production data, material data, and quality data are recorded throughout battery production. By using both HF and UHF RFID solutions from Turck, a battery manufacturer in China has enabled the traceability of materials and components used in production. HF RFID is used mainly on conveyer systems for object identification. UHF RFID is used for logistics and intralogistics in the production facility. The RFID solutions have both read and write functions.

RFID has significant advantages, compared to barcode. The reading speed is much higher, the volume of data that can be stored in RFID tags is also significantly larger. This allows our customers to record not only the batch and production process, but also the environment and production parameters. Barcode tags can also be easily duplicated or copied. From a protection and security point of view, RFID is stronger than barcode.

More Articles on RFID

RFID Systems and Future Trends

Advancing digitalization is having a profound impact on the modern business landscape, particularly through concepts such as Industry 4.0 and the Internet of Things (IoT). These developments use artificial intelligence (AI in business) and machine learning to create intelligent, connected systems that enable more precise and efficient operations management. A key aspect of this is the digital twin and simulation, a digital representation of a physical object or system that enables companies to simulate and optimize processes before they are implemented in the real world.

The integration of AI and machine learning in companies not only leads to improved production lines through the seamless integration of robotics, but also promotes the sustainability of companies. Through intelligent analysis of data, resources can be used more efficiently, emissions reduced, and energy consumption minimized. This contributes to the sustainability of companies and helps companies to act responsibly, both economically and ecologically.

In this context, the IoT plays a crucial role by connecting devices and machines in a way that was previously not possible. This networking enables comprehensive data collection and analysis, which in turn forms the basis for machine learning and adaptive decision-making. The combination of these technologies creates smart factories and operations that embody the basic principles of Industry 4.0 and ushers in a new era of digital economy.

The Profitability of RFID Systems

The market development of RFID technology has made considerable progress in recent years as an increasing number of industries recognize and utilize the numerous benefits of this technology. The introduction of RFID systems is often accompanied by a detailed cost-benefit analysis, which helps companies to weigh up the initial costs against the long-term benefits. These benefits include business process optimization, improved inventory accuracy, increased supply chain efficiency, and enhanced security. In addition, RFID enables a more accurate tracking of products and goods, which can lead to a significant reduction in loss and theft.

The cost of implementing RFID varies depending on the scale and complexity of the system. These costs include hardware, such as tags and readers, software solutions for data processing and integration, and staff training. Despite these initial investments, experience from various application areas shows that RFID systems can offer a high return on investment by improving operational processes and saving costs in the long term.

There are many RFID manufacturers and suppliers on the market offering a wide range of products and solutions for different application needs. These range from simple systems for small companies, to highly complex solutions for global corporate networks. Choosing the right supplier is critical, as it affects the performance and reliability of the entire system. Companies that invest in RFID can benefit from this technology by optimizing their operations and bringing more transparency to their processes.

Partners Spezialized in RFID Products and Solutions

A Combination of Wireless Technologies

In the modern world of technology, different wireless technologies are increasingly being combined in order to make the most of the advantages of individual systems. The integration of RFID with other radio technologies such as UWB (Ultra-Wideband), SAW (Surface Acoustic Wave), BLE (Bluetooth Low Energy) and NFC (Near Field Communication) opens up new possibilities in many application areas. These hybrid solutions can improve positioning accuracy, increase range, and optimize energy consumption.

The use of RFID and UWB, for example, enables very accurate real-time localization, which is particularly useful in complex industrial environments where objects need to be tracked quickly and accurately. RFID and SAW, on the other hand, offer solutions that do not require batteries and are stable, even under extreme environmental conditions, making them ideal for monitoring and maintenance tasks.

By combining RFID and BLE, connectivity to mobile devices such as smartphones or tablets can be simplified, increasing the usability of consumer applications such as personal tracking systems or smart payment systems. NFC, which is often used in conjunction with RFID, enables fast and secure communication over short distances and is often used in retail and contactless payment systems.

Hybrid RFID Solutions: Greater Range and Less Susceptible to Interference

Hybrid RFID solutions that combine high frequency (HF) and ultra high frequency (UHF) technologies offer a flexible and efficient way of utilizing the advantages of both frequency ranges. This combination makes it possible to utilize the greater range and faster data transmission of UHF, as well as the higher security and less susceptibility to interference from metals and liquids of HF. Such systems are particularly beneficial in complex environments such as supply chain management, where items are tracked at different levels and with different requirements.

Mobile and Stationary RFID Systems: RFID Scanners, Tunnel Readers or RFID Gates

The integration of mobile and stationary RFID technology further expands the application possibilities. Stationary RFID solutions integrate RFID tunnels or RFID gates, for example.

Mobile RFID solutions use portable devices such as smartphones or special RFID scanners to increase the flexibility and accessibility of the technology. Users can access and process data in real time, regardless of their location. This is particularly beneficial for employees working in the field, in logistics, or in retail, as they can check inventory levels, locate products, or carry out authentications without being tied to a fixed workstation.

All combinations can optimize data availability, connectivity, productivity, and processes. In addition, these hybrid solutions enable better customization to specific requirements and challenges, making them a valuable investment for many industries.