What are RFID Tags?

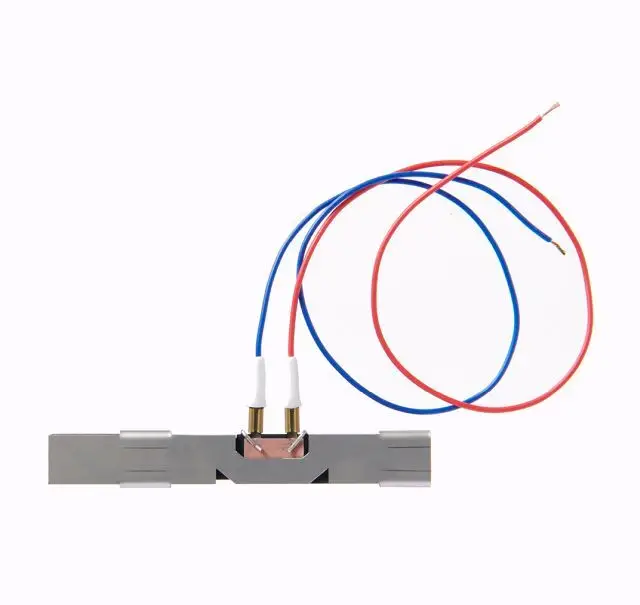

Radio-Frequency Identification (RFID) tags are wireless, small electronic devices used for the identification and asset tracking. These devices are also known as RFID transponders. An RFID tag consists of three main components: An integrated circuit (IC) or microchip, an antenna, and a substrate.

The IC is provided by semiconductor manufacturers and contains a memory storage unit, in addition to a microprocessor. It stores and processes data of the tagged item. Unique identifiers are stored in the IC, for example. On the IC or RFID chip are four memory banks: EPC, User, Reserved, and TID. An RFID tag manufacturer is able to configure the IC to function either passively, or actively. A strip of conductive material like aluminum or copper is usually used as the antenna. This is the largest component in a typical RFID tag, and is embedded in the substrate. The antenna transmits and receives radio signals. Flexible plastic, polymer, or paper material is used as a substrate. This holds the antenna and the IC together.

Additional components include an adhesive that is used to attach the tag to an asset, as well as a face laminate and an encapsulation layer that protects the RFID tag against environmental conditions such as dust, UV, and moisture.

RFID tags come in various different form factors. These include: RFID labels, RFID inlays, glass capsules, discs, rectangular blocks or RFID hard tags, and ISO cards. Other examples include the RFID button tag, the RFID flag tag, the RFID plug tag, or the mini RFID tag. These form factors are customizable according to application requirements. RFID tags can be embedded in tires, be integrated in keyfobs, or built into cable ties, for example. An RFID metal tag, or on-metal RFID tags, are designed to operate in environments close to metal. Heat-resistant RFID tags are designed to withstand extreme heat.

Passive, Semi-Passive, and Active RFID Tags

RFID tags can either be passive, active, or semi-passive. Passive RFID tags have no internal power source and rely entirely on the electromagnetic energy from an RFID reader to operate. Passive RFID tags transmit information on one of three frequencies:

- Low Frequency (LF) | 125-134 KHz

- High Frequency (HF) | 13.56 MHz

- Ultra-High Frequency (UHF) | 865-960 MHz

The read range of the RFID tag depends on the frequency used. LF RFID tags can be read at ranges of up to 10 centimeters. The read range of HF RFID tags is up to 30 centimeters, and for UHF RFID tags, the range is up to six meters.

Part of the HF RFID category are Near-Field Communication (NFC) tags. Unlike RFID tags that can be read in bulk, NFC tags can only be read one at a time. NFC tags also have larger memory units, and enable bidirectional communication.

Each frequency also has standards that must be adhered to. The standards for LF RFID are the ISO 14223 and ISO/IEC 18000-2. The ISO 15693 and ISO/IEC 14443 standards apply for HF RFID. UHF RFID tag manufacturers must ensure that tags conform to the ISO 18000-6C standard.

Active RFID tags, also called battery-operated RFID tags, have their own power source, typically a battery, which allows them to transmit signals over longer distances and often store more data. Active RFID tags transmit data at higher frequencies, like 433 MHz or 915 MHz. Battery-powered RFID tags typically last three to five years.

Semi-passive tags, also known as battery-assisted passive (BAP) RFID tags, also have a battery but only use it to power the IC. They are basically passive tags that have a battery.

How Does an RFID System Work?

An RFID system consists of RFID tags, wireless RFID readers (handheld, fixed, RFID pad, etc.) , RFID antennas, and cables. Sometimes, a system can use an integrated reader that combines antenna, reader, and cabling. The most simply RFID system use RFID tags and an RFID handheld reader.

RFID tags are attached to assets that need to be tracked and identified. These tags transmit data via radio signals an RFID reader. Examples of this data include unique identifiers (UI) for industrial identification, as well as product information like serial numbers, and logistics and manufacturing information. The RFID reader captures the signal and converts it into data that can be used.

The captured data is then transmitted to a host computer system via a communications interface. Here, the data is stored in a database, and is made ready for analysis. From here, specific actions can be triggered, be it activating alarms, updating databases for real-time inventory tracking and asset management, or opening doors, for example.

RFID Tag Products

Applications for RFID Tags

Depending on the frequency and type of RFID tag, many applications are possible. LF RFID tags are commonly used for animal tracking, access control, and for identification applications in metallic environments. This includes tool tracking and management, for example.

HF RFID tags are used for contactless payment systems, in library systems for book tracking and inventory management, as part of ticketing systems for public transport, and as RFID cards or NFC cards for identification and access control. Countries like Australia, India, Japan, Norway, and the USA use HF RFID in passports.

UHF RFID tags are used for supply chain management applications, retail inventory, theft protection, real-time logistics and shipment tracking, vehicle identification, laundry management, race timing, as well as asset and tool tracking. In retail and logistics, hybrid solutions that use RFID and barcode tags are used. A UHF RFID metal tag can be used for tracking in metallic environments.

Active RFID tags are commonly used for vehicle tracking, and for tracking construction equipment and pipes. These tags are often equipped on large outdoor assets.

Example 1: Rentex Tags Film Equipment With RFID

Rentex Optimizes Processes with RFID Technology: Enormous Time and Cost Savings

- Increased Efficiency through RFID: A two-and-a-half hour process that previously required two employees has been transformed into a 15-minute process requiring just one employee thanks to RFID technology. This equates to an impressive 95 percent saving in time and costs.

- Time Savings Through Automated Check-In: Another process that used to take 22 minutes has been replaced by an RFID-supported check-in that takes just ten seconds. This means a time saving of over 99 percent.

Rentex Optimizes Processes with RFID Technology: Enormous Time and Cost Savings

- Increased Efficiency through RFID: A two-and-a-half hour process that previously required two employees has been transformed into a 15-minute process requiring just one employee thanks to RFID technology. This equates to an impressive 95 percent saving in time and costs.

- Time Savings Through Automated Check-In: Another process that used to take 22 minutes has been replaced by an RFID-supported check-in that takes just ten seconds. This means a time saving of over 99 percent.

“Thanks to the integration of RFID technology, Rentex has achieved greater automation and significantly reduced manual workloads. These optimizations lead to significant time and cost savings and set new standards in increasing efficiency.”

Ken Horton

Independent

Example 2: Replenishment System Optimized with RFID

The firefighting equipment manufacturer Rosenbauer automates the management of components with RFID. Employees have to be supplied with the right C-parts in production. This includes items such as protective work clothing, consumables, and tools. Rosenbauer uses RFID-tagged KLT boxes from RECA for delivery. The containers should be in a permanent cycle between the C-parts warehouse and the production line. This ensures a seamless supply of parts.

Before the use of RFID technology, there were occasional delays in the material flow. RFID-tagged KLT boxes are detected by RFID gates. Empty and full containers are automatically distinguished from each other.

The firefighting equipment manufacturer Rosenbauer automates the management of components with RFID. Employees have to be supplied with the right C-parts in production. This includes items such as protective work clothing, consumables, and tools. Rosenbauer uses RFID-tagged KLT boxes from RECA for delivery. The containers should be in a permanent cycle between the C-parts warehouse and the production line. This ensures a seamless supply of parts.

Before the use of RFID technology, there were occasional delays in the material flow. RFID-tagged KLT boxes are detected by RFID gates. Empty and full containers are automatically distinguished from each other.

“Today, we no longer have unwanted production breaks due to missing C-parts. The boxes deliver reliably, fully, and just-in-time. The zero-defect solution has also given us a read accuracy of near 99 percent.”

Manuel Schwarzbauer

Head of Logistics Plant 1