What Can RTLS Do?

RTLS is a technological system that can detect and track the exact position of objects or people in real time. RTLS uses various technologies and methods for this purpose. Real-Time Location Systems offer numerous advantages, particularly in terms of safety, efficiency, and workflow management. This leads to greater efficiency and reduces the need for manual intervention. Autonomous vehicles in warehouses and production facilities can optimize their routes and react automatically to changing conditions, for example.

RTLS and Wireless IoT

Sensors, UWB, RFID, and BLE play an important role in RTLS systems. Sensors capture precise data on position and movement in real time. UWB (Ultra-Wideband) offers high localization accuracy and is particularly suitable for industrial applications. RFID (Radio Frequency Identification) makes it easy to track objects and is often used in logistics. BLE (Bluetooth Low Energy) is energy-efficient and ideal for mobile and cost-effective applications. Together, these technologies enable reliable and efficient real-time localization in various industries.

Technologies

Understanding "Real Time"

The term real-time refers to the ability of an IT system to react within a certain time frame. According to DIN ISO/IEC 2382, the term "real-time" describes the ability of a system to react immediately to inputs or events so that the results are available within a clearly defined and often very short time frame - without any perceptible delay.

Immediate Reaction A real-time system must react immediately to incoming data or events.

Defined Time Frames The time within which the system must react is fixed and varies depending on the application. This period can range from a few milliseconds to several seconds or even minutes.

Continuous and Reliable Operational Readiness Programs and systems that work in real time must be constantly ready to process data and take appropriate action.

Evaluation and Time Window The evaluation and analysis of real-time data can increase the transparency of processes, improve planning reliability or identify potential sources of error at an early stage. The time window for data acquisition is not fixed and can vary from a few milliseconds to several hours, depending on the application.

Conclusion Real-time means the technical ability to retrieve data at the moment it happens. The system tracks the exact location of something and updates the RFID tracking information in real time. This means that the system is always up-to-date and precise.

Facts & Figures

According to a report by the Indian information and market research platform "Markets and Markets", the global RTLS market was estimated at 5.2 billion USD in 2023. This figure is expected to rise to 16.2 billion USD by 2028, with the highest growth rates expected for the Asia-Pacific region. This is due to the rapidly growing manufacturing sector in China. Japan, South Korea, China, and Australia are also experiencing high demand and adoption of RTLS technologies, especially for healthcare applications such as the improvement of patient safety.

RTLS systems are divided into segments consisting of hardware, software, and services. According to a report by the American market research and management consulting company "Global Market Insights", hardware accounted for around 50 percent of the RTLS market share in 2022. RTLS systems can consist of various wireless technologies, including RFID, Wi-Fi, UWB, BLE, and GPS, to name a few. RFID accounted for 30 percent of the RTLS market share in 2022.

North America held the largest share of the global RTLS market in 2022 at 45 percent. This is due to the increasing adoption of RTLS in the automotive, healthcare, logistics, manufacturing, retail, and transportation sectors. In North America, Wi-Fi was the predominant technology used for RTLS systems.

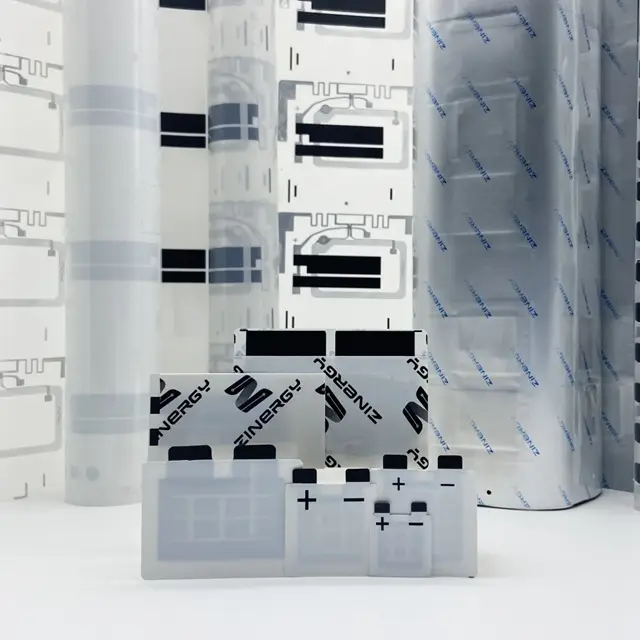

Products Designed for the RTLS Sector

Which Hardware Components are Part of an RTLS Solution?

RTLS often uses radio frequency signals such as Wi-Fi, Bluetooth or ultra-wideband (UWB) technology to locate and track people, objects or vehicles. How does it work? A transponder or sensor is attached to the asset. This emits radio signals. In the area to be covered by RTLS, there are receivers that receive the radio signals.

The receivers triangulate the signals, and can thus determine the exact location of each item. In simple terms: The wireless network consists of sensors, transponders, and receivers. Together with an IT system, these components can detect movements and objects. As soon as an object is identified, its precise position can also be determined.

An RTLS solution includes various hardware components that work together. These include:

Tags: These are attached to objects or people.

Anchors: Stationary receivers that receive the signals from the tags.

Gateway: A device that collects and forwards the data from the anchors.

Server: Processes and stores the location data.

User Interface: For visualising and analysing the data.

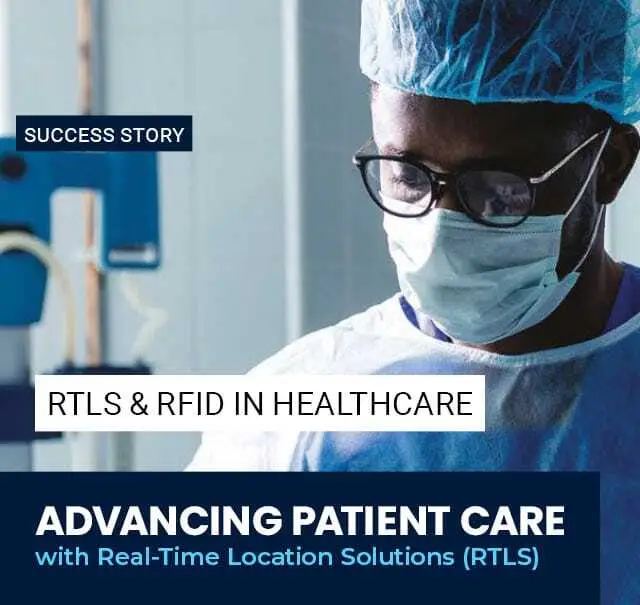

Mayo Clinic: Solution for Staff Emergencies

A mobile solution for emergency situations has been introduced at Mayo Clinic in Rochester, Minnesota. This portable solution is based on BluFi, BLE, and RTLS technology. The hospital in Rochester has installed 13,200 BluFi readers and 15,100 Asset Beacons. 7,000 employees each received a badge with an integrated BLE beacon.

The beacon communicates with the hospital's installed RTLS infrastructure by actively transmitting signals on different frequencies. A button located behind the cover of the badge activates an emergency signal when pressed. BluFi BLE antennas and receivers capture the signal, communicate over a mesh network, and coordinate with Wi-Fi gateways to transmit the data to a cloud-based Software-as-a-Service (Saas): HID's Bluzone Cloud.

Data cleansing technologies in the cloud determine the employee's location based on signal thresholds for each antenna. The hospital's security team is able to identify the employee's identity, occupation, and current location via the system in the event of an emergency. By continuously updating the location, the security team can determine the exact position of the employee even after a change of location.

Upon arrival, standard protocols are followed and an incident report is generated. During the 12-month project, 167 emergency calls were registered. Further testing reduced the false alarm rate from 32 percent to 11 percent. As a result of the solution, 84 percent of Rochester hospital staff feel safe at work.

A mobile solution for emergency situations has been introduced at Mayo Clinic in Rochester, Minnesota. This portable solution is based on BluFi, BLE, and RTLS technology. The hospital in Rochester has installed 13,200 BluFi readers and 15,100 Asset Beacons. 7,000 employees each received a badge with an integrated BLE beacon.

The beacon communicates with the hospital's installed RTLS infrastructure by actively transmitting signals on different frequencies. A button located behind the cover of the badge activates an emergency signal when pressed. BluFi BLE antennas and receivers capture the signal, communicate over a mesh network, and coordinate with Wi-Fi gateways to transmit the data to a cloud-based Software-as-a-Service (Saas): HID's Bluzone Cloud.

Data cleansing technologies in the cloud determine the employee's location based on signal thresholds for each antenna. The hospital's security team is able to identify the employee's identity, occupation, and current location via the system in the event of an emergency. By continuously updating the location, the security team can determine the exact position of the employee even after a change of location.

Upon arrival, standard protocols are followed and an incident report is generated. During the 12-month project, 167 emergency calls were registered. Further testing reduced the false alarm rate from 32 percent to 11 percent. As a result of the solution, 84 percent of Rochester hospital staff feel safe at work.

"The IT platform was already helping us doctors with diagnosis, locating objects and workflows. Now, with Staff Duress, a crucial application for the safety of our 7,000 employees has been added."

Derick D. Jones

Emergency Medicine Physician Board Certified in Clinical Informatics and Chair in RFID Technology at Mayo Clinic in Rochester, Minnesota

Toro Aluminium: Identification and Localization of Windows with RFID

Toro Aluminium, a Canadian supplier of windows and doors for high-rise buildings, has been using UHF RFID to identify prefabricated aluminium components since 2023. Over 3,000 components are produced every week. The aluminum profiles are cut to size using CNC machines.

RFID printers integrated into the CNC machines generate coded RFID labels with production data such as dimensions. These are linked to the ERP system. The aluminum profiles are then assembled on one of 10 assembly lines, each equipped with two RFID ceiling antennas from FEIG Electronic. Assembly begins after the ID of the component has been detected by the antennas.

In some cases, the windows must be temporarily stored in a holding or quarantine warehouse before being moved to the final assembly and inspection point. Ceiling-mounted antennas enable the localization of all windows in the warehouse in real time. Information about the location of individual components and the duration of storage is stored in the ERP system.

RFID antennas with indicator lights from Times-7 are fitted to the gates in the outgoing goods area. These antennas record the ID of each window that passes through the gates. The ERP system then creates a delivery bill for the order. The indicators on the RFID antennas light up red when windows that do not belong to a specific order are detected. This ensures that no windows are delivered by mistake.

At the construction site, the customer uses an RFID handheld with RFID Canada's RFID To Go software to check the completeness of the delivery. If the delivery is error-free, the ERP system is notified. The order is then marked as successfully delivered.

Toro Aluminium, a Canadian supplier of windows and doors for high-rise buildings, has been using UHF RFID to identify prefabricated aluminium components since 2023. Over 3,000 components are produced every week. The aluminum profiles are cut to size using CNC machines.

RFID printers integrated into the CNC machines generate coded RFID labels with production data such as dimensions. These are linked to the ERP system. The aluminum profiles are then assembled on one of 10 assembly lines, each equipped with two RFID ceiling antennas from FEIG Electronic. Assembly begins after the ID of the component has been detected by the antennas.

In some cases, the windows must be temporarily stored in a holding or quarantine warehouse before being moved to the final assembly and inspection point. Ceiling-mounted antennas enable the localization of all windows in the warehouse in real time. Information about the location of individual components and the duration of storage is stored in the ERP system.

RFID antennas with indicator lights from Times-7 are fitted to the gates in the outgoing goods area. These antennas record the ID of each window that passes through the gates. The ERP system then creates a delivery bill for the order. The indicators on the RFID antennas light up red when windows that do not belong to a specific order are detected. This ensures that no windows are delivered by mistake.

At the construction site, the customer uses an RFID handheld with RFID Canada's RFID To Go software to check the completeness of the delivery. If the delivery is error-free, the ERP system is notified. The order is then marked as successfully delivered.

"The purpose of this project was to compare the results of the RFID system with the results of the current barcode system The results were clear and showed the potential of RFID technology. The automated and contactless processes are superior to the manual barcode process. The decision to start the installation was therefore made very quickly."

Khaled Elshimy

CEO

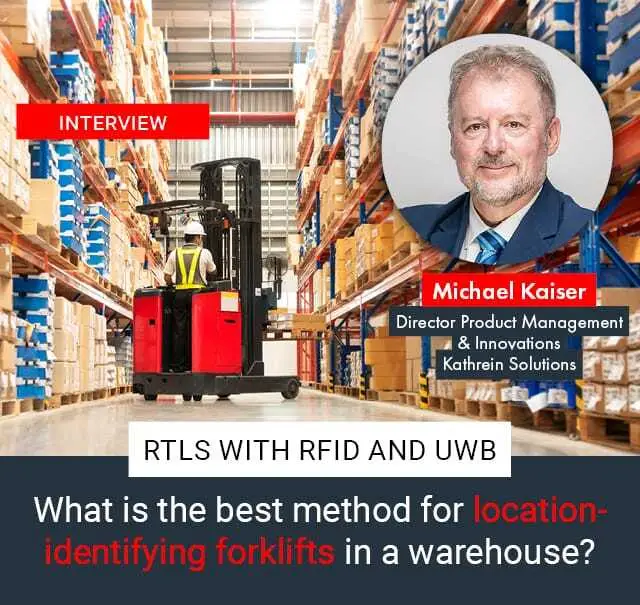

TB International: Indoor Real-Time Localization with RFID and UWB for Logistics

Fashion wholesaler TB International tracks the movements of all goods and vehicles in its 25,000 m² warehouse in Groß Gerau in real time using UHF RFID tags and UWB sensors. All boxes in the warehouse are fitted with UHF RFID tags from deister electronic.

All 40 forklift trucks are equipped with two RFID readers from Cisper Electronics and a UWB vehicle tag to transmit position data. The aisles of the warehouse are also equipped with UWB sensors. This allows the positions of the forklift trucks and the individual boxes to be recorded in real time with an accuracy of 10 cm.

When goods are received in the warehouse, digital twins are created and transferred to the SAP ERP system via an IoT platform. This digital IoT platform enables the generation of position data as well as the management and visualization of the UWB sensors. The mapped data from all digital twins provides an overview of all logistics and material flows. Optimal forklift routes are calculated and displayed to the forklift driver.

Fashion wholesaler TB International tracks the movements of all goods and vehicles in its 25,000 m² warehouse in Groß Gerau in real time using UHF RFID tags and UWB sensors. All boxes in the warehouse are fitted with UHF RFID tags from deister electronic.

All 40 forklift trucks are equipped with two RFID readers from Cisper Electronics and a UWB vehicle tag to transmit position data. The aisles of the warehouse are also equipped with UWB sensors. This allows the positions of the forklift trucks and the individual boxes to be recorded in real time with an accuracy of 10 cm.

When goods are received in the warehouse, digital twins are created and transferred to the SAP ERP system via an IoT platform. This digital IoT platform enables the generation of position data as well as the management and visualization of the UWB sensors. The mapped data from all digital twins provides an overview of all logistics and material flows. Optimal forklift routes are calculated and displayed to the forklift driver.

"RFID is the technology of the future in logistics and retail. Much more is possible. Now that all 40 forklift trucks in Groß Gerau are equipped with readers and the technology has been implemented in the warehouse, we can add new use cases as an extension at any time."

Johannes Rudenko

Business economist

Is RTLS a Megatrend?

Absolutely. The enormous growth figures are proof of this. RTLS is increasingly being used across industries and is having a transformative impact on business processes and technologies.

Industry 4.0 and IoT RTLS plays a crucial role in the fourth industrial revolution (Industry 4.0) and the Internet of Things (IoT). The ability to localize and track objects and people in real time enables improved automation, efficiency, and transparency in production and logistics processes.

Logistics and Supply Chain Management In logistics and supply chain management, RTLS improves inventory management, optimizes the flow of goods, and reduces losses. Real-time data on the location of goods and assets enables more precise planning and faster reactions to changes in the supply chain.

Healthcare In the healthcare sector, RTLS is used to track medical equipment, staff, and patients. This leads to a better use of resources, increases patient safety, and improves the efficiency of processes in hospitals and care facilities.

Retail In retail, RTLS helps optimize inventory, track merchandise, and improve the customer experience through personalized offers and navigation in large shopping malls. Security and Emergency Management RTLS enables improved security in companies and public facilities by tracking people and assets. In emergencies, the technology can help to locate and evacuate people more quickly.

Smart Buildings and Smart Cities In smart buildings and cities, RTLS helps to increase efficiency and improve quality of life by enabling the monitoring and control of resources such as energy, water, and transportation.

Advantages of RTLS for Security

Distance and Safety Zone RTLS enables the automatic monitoring of safety distances of employees or vehicles. This can prevent accidents on factory premises and in logistics areas. By defining safety zones, warnings can be issued automatically when employees approach these areas.

Infection Chains Another advantage of RTLS is the tracking of infection chains. In the event of a disease outbreak such as corona, it is possible to trace which employees have been in contact with each other. This enables the rapid and targeted quarantine of affected persons and minimizes the risk of the infection spreading further.

Employee Safety Emergency situations can be identified more quickly thanks to the real-time monitoring of fire and rescue services. In the event of accidents, the system automatically triggers an alarm. Shorter response times increase the rescue potential.

Warnings RTLS systems can issue warnings that are individually configurable. These warnings can be of a preventative nature, for example when approaching dangerous machines or areas, or in the event of an emergency when rapid assistance is required. This proactive safety measure increases employee awareness of potential hazards and reduces the risk of accidents.

Advantages of RTLS for Operational Processes

Advantages at a Glance!

- Real-time Visibility

- Inventory Optimization

- Increased Efficiency

- Theft protection

- Improved Delivery Accuracy

- Process Optimization

Transaction Data With RTLS, personnel routes can be precisely controlled and optimized. Unnecessary routes are avoided and work processes are better organized. Warehouse workers can be guided directly to the required shelves without wasting time, for example. The analysis of employee movement data also provides valuable insights into the use of space and the efficiency of work processes. Companies can also use this data to identify bottlenecks.

Production Optimization RTLS enables accurate tracking of materials and products within the production facility. This leads to better inventory control and reduces production delays.

Maintenance Management Machines and equipment can be monitored in real time. This enables predictive maintenance and reduces downtime.

Equipment Inventory and Asset Management Medical devices, equipment, or goods and inventory can be tracked in real time to ensure their availability and maximize efficiency of use.

Supply Chains Real-time tracking of shipments and vehicles enables better planning and coordination of transportation routes. This reduces delivery times and costs.

Industry and Logistics Real-Time Location Systems (RTLS) offer significant advantages for efficiency and optimization in various areas, especially in industry and logistics. Here are some of the most important advantages, taking into account the mentioned keywords:

Improved Business Decisions By using RTLS, companies gain valuable insights into their operations. The location data collected enables informed business decisions as it provides an accurate overview of the current situation. Managers can use this information to make strategic decisions that increase efficiency and productivity and reduce costs.

Live Map of Production Areas One of the most important applications of RTLS is the creation of live maps of production areas. These maps show the position of machines, vehicles, and employees in real time. This allows managers to react quickly to changes, such as accidents or production disruptions, and take immediate action to restore normal operations.

Filters Enable Data Analysis RTLS systems have powerful filter functions that make it possible to analyze large amounts of location data. These filters can pick out specific data points to create detailed analyses and reports. Companies can use these analyses to recognize patterns, improve efficiency, and identify problem areas.

Plant Efficiency

RTLS significantly improves the efficiency of plants and logistics processes. By precisely tracking machines, materials, and products in real time, companies can identify and eliminate bottlenecks. This leads to a smoother production and a better utilization of available resources. In addition, the lead time of products in the supply chain is reduced, resulting in faster order processing.

Digital Twins through Location Data

The integration of RTLS enables the creation of digital twins, i.e. virtual images of physical plants and processes based on real-time location data. These digital twins provide a detailed and up-to-date overview of the status and position of assets. This facilitates the planning, monitoring, and optimization of operational processes and supports predictive maintenance.

Transaction Data With RTLS, personnel routes can be precisely controlled and optimized. Unnecessary routes are avoided and work processes are better organized. Warehouse workers can be guided directly to the required shelves without wasting time, for example. The analysis of employee movement data also provides valuable insights into the use of space and the efficiency of work processes. Companies can also use this data to identify bottlenecks.

Production Optimization RTLS enables accurate tracking of materials and products within the production facility. This leads to better inventory control and reduces production delays.

Maintenance Management Machines and equipment can be monitored in real time. This enables predictive maintenance and reduces downtime.

Equipment Inventory and Asset Management Medical devices, equipment, or goods and inventory can be tracked in real time to ensure their availability and maximize efficiency of use.

Supply Chains Real-time tracking of shipments and vehicles enables better planning and coordination of transportation routes. This reduces delivery times and costs.

Industry and Logistics Real-Time Location Systems (RTLS) offer significant advantages for efficiency and optimization in various areas, especially in industry and logistics. Here are some of the most important advantages, taking into account the mentioned keywords:

Improved Business Decisions By using RTLS, companies gain valuable insights into their operations. The location data collected enables informed business decisions as it provides an accurate overview of the current situation. Managers can use this information to make strategic decisions that increase efficiency and productivity and reduce costs.

Live Map of Production Areas One of the most important applications of RTLS is the creation of live maps of production areas. These maps show the position of machines, vehicles, and employees in real time. This allows managers to react quickly to changes, such as accidents or production disruptions, and take immediate action to restore normal operations.

Filters Enable Data Analysis RTLS systems have powerful filter functions that make it possible to analyze large amounts of location data. These filters can pick out specific data points to create detailed analyses and reports. Companies can use these analyses to recognize patterns, improve efficiency, and identify problem areas.

Plant Efficiency

RTLS significantly improves the efficiency of plants and logistics processes. By precisely tracking machines, materials, and products in real time, companies can identify and eliminate bottlenecks. This leads to a smoother production and a better utilization of available resources. In addition, the lead time of products in the supply chain is reduced, resulting in faster order processing.

Digital Twins through Location Data

The integration of RTLS enables the creation of digital twins, i.e. virtual images of physical plants and processes based on real-time location data. These digital twins provide a detailed and up-to-date overview of the status and position of assets. This facilitates the planning, monitoring, and optimization of operational processes and supports predictive maintenance.

Advantages at a Glance!

- Real-time Visibility

- Inventory Optimization

- Increased Efficiency

- Theft protection

- Improved Delivery Accuracy

- Process Optimization