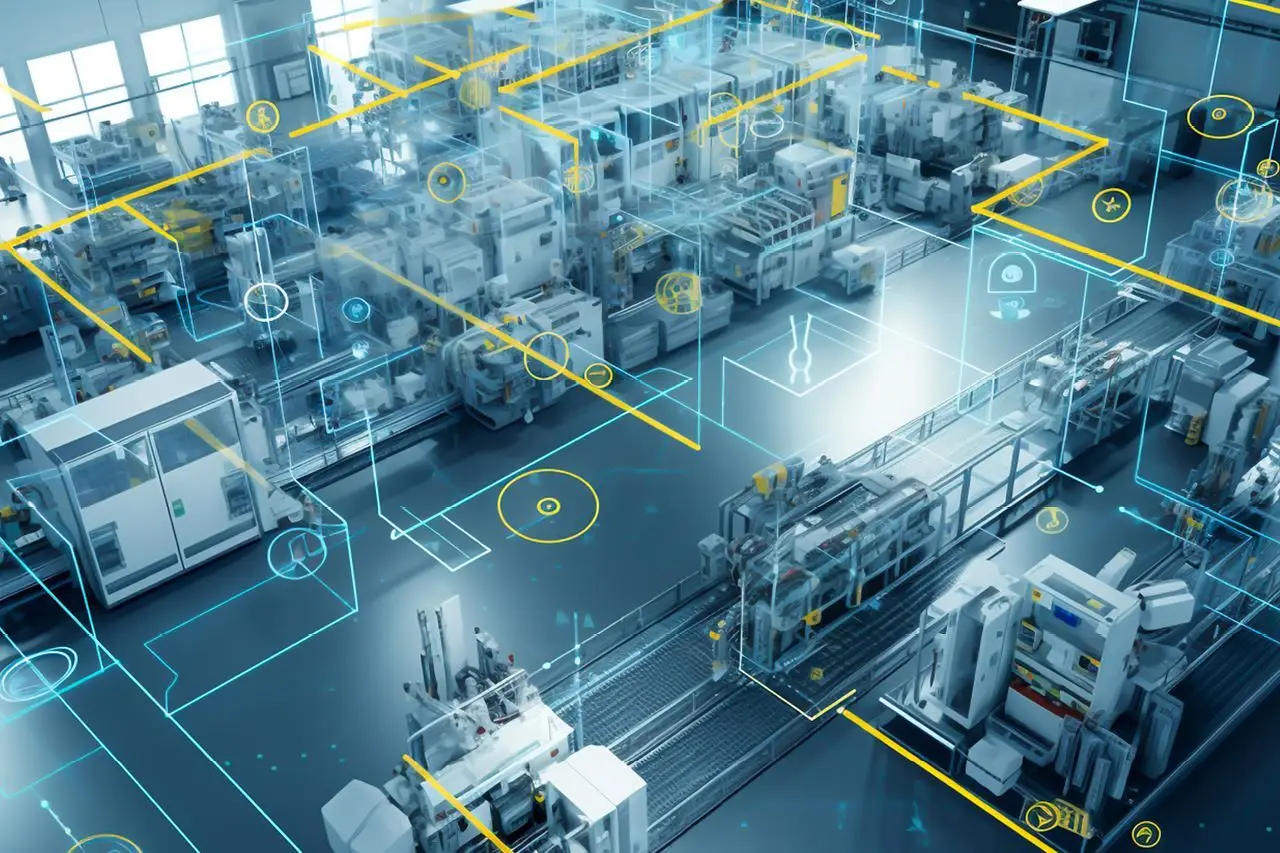

What is Industry 4.0?

Industry 4.0 stands for the intelligent networking of machines and processes in industry with the help of information and communication technologies. The term was first used at the Hannover Messe trade fair in 2011 and describes a new level of organization and control of the entire value chain across the life cycle of products. Core technologies such as IoT, AI, cyber-physical systems and cloud computing play a central role here.

Who Invented or Shaped Industry 4.0?

The term "Industry 4.0" was coined by a group of German scientists and business people. This group first presented the concept at the Hannover Messe trade fair in 2011. It was part of a German government strategy to drive forward the digitalization of the manufacturing industry and ensure the country's competitiveness in an increasingly globalized economy. The influential figures include the members of the Industry 4.0 platform, an alliance of politicians, industry, and science.

Wireless IoT Technologies

Products Designed for Industry 4.0

What Changes Does Industry 4.0 Bring to Factory Processes?

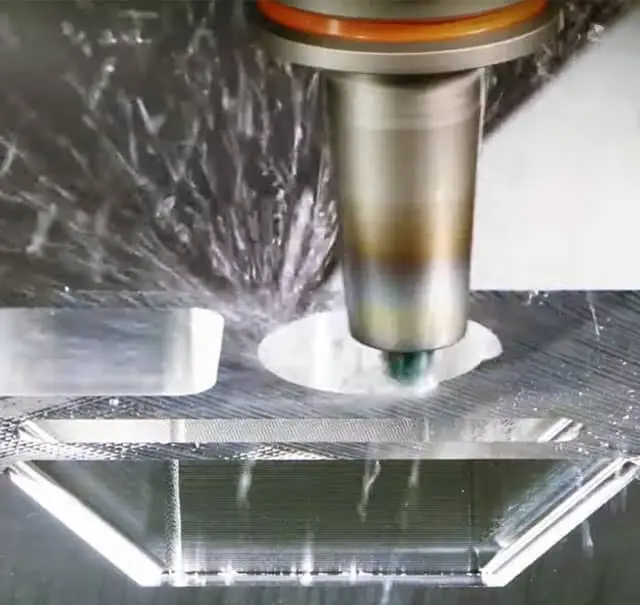

Industry 4.0 is transforming factories into intelligent production facilities in which machines, systems, and products are networked with each other and communicate in real time. This leads to comprehensive automation and the optimization of production processes. Important changes include:

- RTLS: Production data is collected and analyzed in real time in order to be able to react immediately to deviations and faults.

- Predictive Maintenance: Machines monitor their own condition and report maintenance requirements before breakdowns occur.

- Increased Flexibility in Production: production facilities can be quickly adapted to new product variants and customer requirements.

- Resource Efficiency: Through precise monitoring and control, resources are used more efficiently and waste is minimized.

What Are the Benefits of Industry 4.0 for the Industry?

Industry 4.0 offers numerous advantages for the digitalization of industry.

- Increased Efficiency: Automation and real-time data analysis increase productivity and reduce production costs.

- Flexibility: Intelligent production systems enable rapid adaptation to market changes and customer-specific requirements.

- Sustainability: Optimized processes and use of resources reduce the environmental impact.

- Quality Improvement: Continuous monitoring and analysis lead to improved product quality, lower error rates, and worker safety.

- Competitiveness: Companies that use Industry 4.0 technologies are better able to compete in an increasingly global market.

Which Sectors Benefit from Industry 4.0?

Industry 4.0 offers benefits for a wide range of sectors, including:

- Automotive Industry: Networked manufacturing processes and predictive maintenance make production more efficient and flexible.

- Electronics and High-Tech Industry: Highly complex production processes benefit from real-time monitoring and control.

- Chemical Industry: Improved process control and monitoring increase efficiency and safety.

- Food and Beverage Industry: Traceability and quality control are improved by networked systems.

- Mechanical Engineering: Adaptable production systems enable the manufacture of customized products.

Industry 4.0 represents a major step towards networked, intelligent, and sustainable production. Companies that successfully implement these technologies can significantly increase their competitiveness and prepare themselves for the future.

Industry 4.0 in Transportation Logistics

Digitalization in traffic, retail, general logistics and facility management in particular are benefiting significantly from these innovations. This article looks at how Industry 4.0 is transforming these sectors and the benefits that result. Industry 4.0 is revolutionizing transport logistics through the introduction of connected and automated systems. These developments are leading to optimized transport planning and execution:

- Real-Time Monitoring and Control: With the help of IoT sensors and GPS tracking, transport vehicles can be monitored in real time. This enables precise control and adjustment of route planning to minimize delays and optimize delivery times. Temperature monitoring is also part of this.

- Predictive Maintenance: By continuously monitoring the condition of the vehicle, maintenance requirements can be identified and planned at an early stage. This reduces unexpected downtimes and increases the availability of the transport fleet.

- Automation and Robotics: Self-driving vehicles and autonomous storage systems speed up the transportation process and improve efficiency. Robots can move heavy loads and perform repetitive tasks, which increases productivity.

Industry 4.0 in Retail

Industry 4.0 is also significantly changing digitalization in retail. Intelligent systems and data-driven decisions are improving the shopping experience and operational processes:

- Personalization and Customer Analysis: By analysing customer data, retail companies can provide personalized offers and recommendations. This increases customer satisfaction and strengthens customer loyalty.

- Permanent Inventory: IoT sensors enable precise monitoring of stock levels in real time. Automated ordering systems ensure that goods are reordered in good time, avoiding bottlenecks and reducing storage costs.

- Omnichannel Strategies: Networked systems enable seamless integration of online and offline sales channels. Customers can order goods online and pick them up in-store or vice versa, which increases flexibility and convenience.

Industry 4.0 in Logistics

The digitalization of logistics also benefits considerably from Industry 4.0 technologies. The digitalization and networking of logistics processes increases efficiency and transparency:

- Supply Chain Visibility: By integrating IoT and big data, companies can monitor the entire supply chain in real time. This improves transparency and enables a faster response to disruptions.

- Autoamted Warehouse Management: Automated warehouse systems and drones for stocktaking enable precise and efficient inventory management. This reduces errors and increases the speed of order picking and delivery.

- Transport Management: Intelligent transport management systems optimize route planning and freight consolidation. This lowers transport costs and reduces CO2 emissions through more efficient use of transport capacities.

Industry 4.0 in Facility Management

Industry 4.0 also brings significant improvements to facility management through intelligent building management and automated processes:

- Energy and Resource Management: By networking building systems, energy consumption and resource use can be monitored and optimized in real time. This leads to cost savings and sustainable building management.

- Smart Maintenance: Predictive maintenance enables the early detection of maintenance requirements in buildings. This reduces downtimes and extends the service life of installations and systems.

- Security Management: Networked security systems monitor buildings around the clock and can automatically take action in the event of security incidents. This increases the security and protection of buildings and their residents.

What Does Industry 4.0 Have To Do With IoT?

The Internet of Things (IoT) is an essential component of Industry 4.0 and forms the basis for networking and communication between machines, systems, and products. IoT makes it possible to equip physical objects with sensors, software, and other technologies to collect and exchange data. Here are some important connections between Industry 4.0 and IoT:

- Machine Control: IoT enables the wireless networking of machines and devices within a production plant. This networking creates an integrated system that collects and processes data in real time in order to optimize production processes.

- Data Management and Decision-Making: IoT devices continuously collect data on the condition and performance of machines. This data is analyzed to identify patterns and perform predictive analyses. This supports decision-making and improves the efficiency and reliability of production processes.

- Remote Monitoring and Control: With IoT, production processes can be monitored and controlled remotely. This is particularly useful for globally operating companies that want to monitor and optimize their production facilities worldwide in real time.

- Supply Chain Integration: IoT not only connects production facilities, but also the entire supply chain. This enables seamless communication and coordination between suppliers, manufacturers and customers, resulting in a more efficient and transparent supply chain.

- Increased Security: By networking and monitoring production processes, security risks can be detected and rectified at an early stage. IoT-based security solutions improve occupational safety and protect against cyber threats.

How Does Industry 4.0 Improve Digitalization?

Industry 4.0 improves digitalization by introducing cutting-edge technologies and digital solutions into production processes. Here are some key areas where Industry 4.0 is driving digitalization:

- Real-Time Data Processing: By networking machines and systems, data can be captured and analyzed in real time. This enables faster and more informed decisions, leading to greater efficiency and productivity.

- Automation: Industry 4.0 relies on advanced automation technologies such as robotics and AI to take over repetitive tasks and minimize human error. This improves the accuracy and speed of production processes.

- Smart Factories: With the help of cyber-physical systems (CPS) and IoT, factories are being transformed into intelligent production facilities. These systems can independently exchange data and react to changes in the production environment.

- Predictive Maintenance: By continuously monitoring machines and systems, potential problems can be detected and rectified at an early stage before they lead to breakdowns. This significantly reduces downtime and maintenance costs.

- Flexibility and Adaptability: Digitalized production systems can react quickly to changes in demand or production requirements. This enables customized production and shortens the time to market for new products.