NEOSID

We are NEOSID

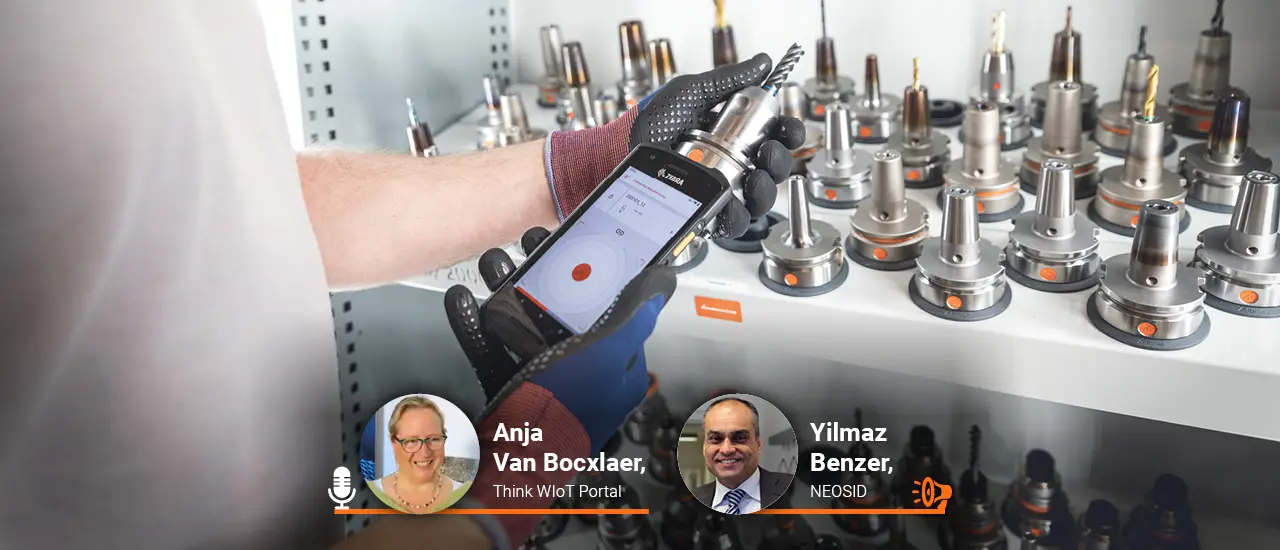

Yilmaz Benzer

Managing Director

"Neosid is a reliable long-term partner for our customers all over the world. With our passion for innovation and our quality requirements for our products, we aim for the highest customer satisfaction. Our fully automated manufacturing system in Halver, Germany made it possible for us to redefine reliable RFID technology."

Redefining Reliable RFID Technology

NEOSID develops, manufactures, and supplies ferrite components, inductors, RFID antennas, and RFID transponders. Upon request, customized products are also available.

NEOSID has redefined reliable RFID technology by developing miniaturised HF transponders at a size of 2.6 x 2.4mm and 2.6 x 5.9mm. The incredibly small NeoTAG® transponders resist the most challenging conditions and have a remarkable reading range – even in metallic environments. The NeoTAG® plug version comes with press-fit case for quick and easy assembly.

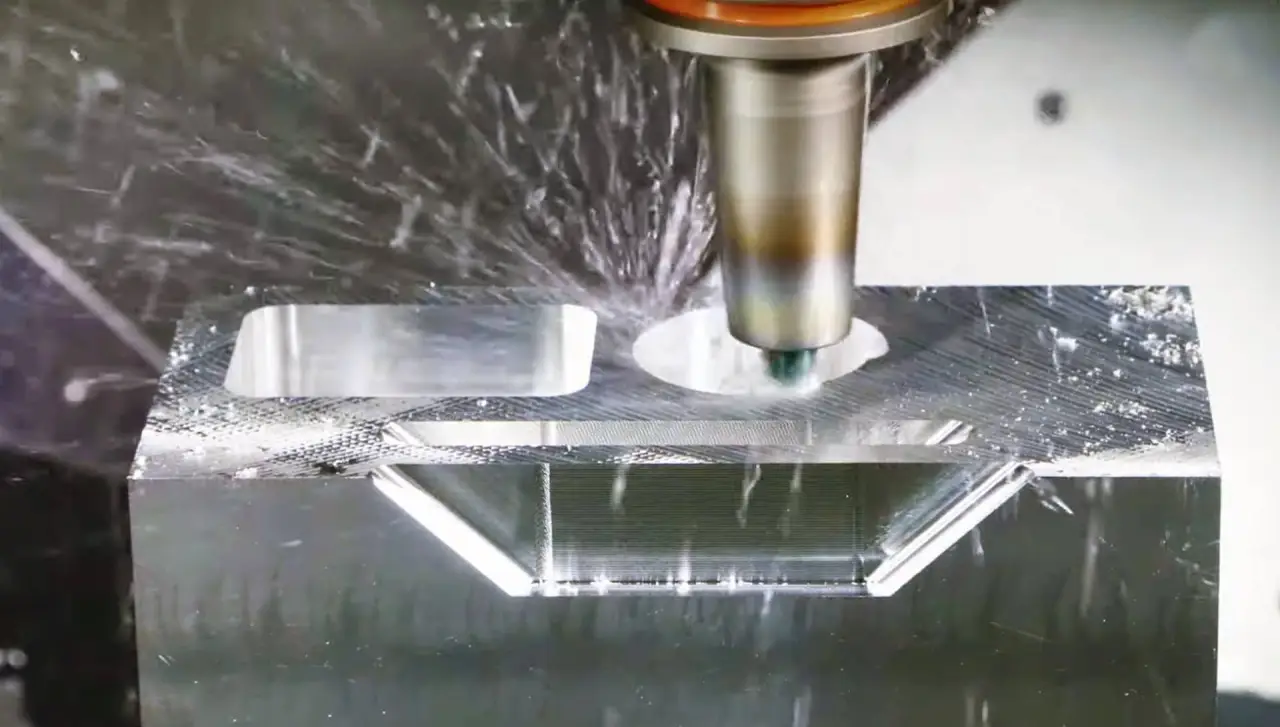

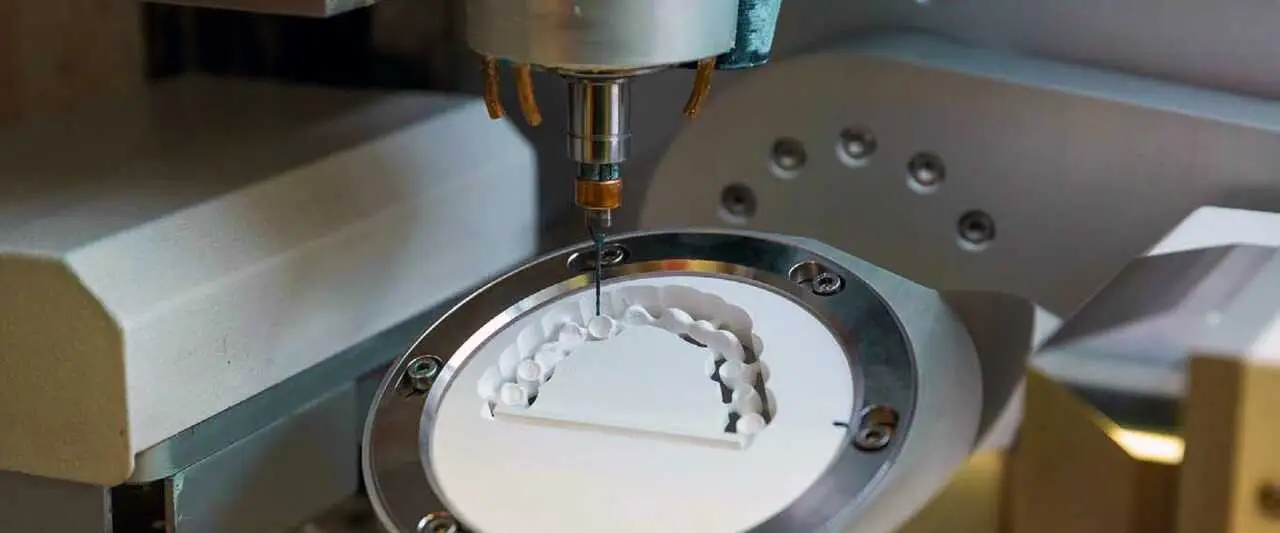

By its notable robustness against environmental influences and sterilisation processes the NeoTAG® transponder is the perfect solution for RFID implementation into a wide range of high-class technologies. A selection of the wide range applications areas is tool making and management, maintenance and upkeep, medical instruments and applications and as well as consumer products. The NeoTAG® transponders are a perfect way to support your IoT application.

The New Dimension in Transponder Technology

NeoTAG® products can resist short term exposure of up to 275°C for 15 minutes, offering a new dimension in transponder technology. For operating temperature range and additional conditions please mind the chip manufacturer’s data sheet.

The NeoTAG is fully automated produced "Made in Germany". Highest quality and reliability is guaranteed. The ISO/TS 16949 certification is NEOSIDs quality standard. The certification according to ISO 14001 standard confirms our environmental responsibility.

We provide ferrites and antenna development for LF, HF and UHF transponders and reader solutions. Miniature RFID-HF transponder used as inlay and plug version for harsh environments are our expertise.

- Logistics

- Industrial Manufacturing

- Retail

- Smart City

- Construction Industry

- Healthcare

- Energy Industry

Success Stories with Neosid

News from Neosid

Products of Neosid

We’re Here For You!

Yilmaz Benzer

Managing Director

Matthias Höß

Manager R&D and Project Management