What is IoT Asset Management?

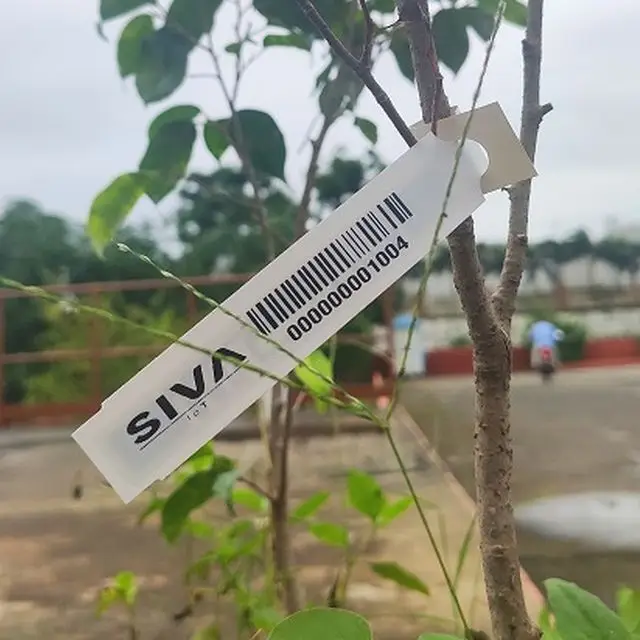

Assets are capital goods or inventories of companies or institutions. These include machines, tools, molds, equipment, and objects such as furniture or fire extinguishers, as well as roll containers, vehicles, or elevators. Collectively, movable or immovable fixed assets belong to the group 'assets'. Management stands for administration, maintenance, control, and localization. To ensure that assets can be identified and located, they must be clearly labeled. This is the only way to digitize asset management. This is the beginning of asset management and inventory of the future in the IoT.

Wireless IoT Technologies and Asset Management

Integration of Hardware and Software for Asset Management

The integration of asset management hardware and asset management software technologies plays a key role in IoT asset management. On the hardware side, stationary and mobile wireless RFID readers, RFID portals, antennas, robots, LoRaWAN, BLE or RTLS gateways, BLE-enabled tablets and smartphones, as well as barcode scanners and wireless label printers are used. Different hardware systems are implemented depending on the technology used (RFID, BLE, LPWAN, and RTLS).

In addition, a variety of components such as GPS trackers, transponders, labels, sensors, actuators, and embedded systems can be used. They capture, monitor and control the assets. These sensors can continuously measure data such as temperature, pressure, vibrations, and operating states, and transmit them to central data storage or cloud platforms via wireless networks.

On the asset management software side, the technology portfolio includes solutions for data management, analytics, and applications for visualizing asset data. Databases and big data platforms are used to store and process large volumes of asset data, while advanced analysis techniques such as machine learning and artificial intelligence help to identify patterns and deviations in the data. Based on this, predictive maintenance models are developed, decision support systems are created, and performance indicators are generated. Furthermore, IoT platforms and middleware provide interfaces for the integration of hardware and software components.

Facts & Figures

According to the strategic management firm ‘Virtue Market Research’, the global market for asset management with IoT solutions was worth 24 billion USD in 2022. This number is expected to grow to over 40 billion USD by 2030. This growth is fueled by the increasing demand for remote asset management solutions and predictive maintenance, and the decreasing cost of IoT sensors. In 2021, the largest market share by industry for the implementation of IoT-based asset management solutions was held by the manufacturing industry at 35 percent.

Asset Management Solutions with IoT

The management of assets is crucial for success for companies in many industries. The following solutions, based on real-life success stories, show different asset management solutions in different industries: The film industry, industrial production, and in healthcare. These solutions reveal the methods, like industrial identification, and resulting benefits of asset management solutions with IoT.

Film Equipment Supplier Rentex Tracks Assets with UHF RFID

The use of RFID tags on rental objects makes product identification much easier. US film equipment rental company Rentex, for example, has worked with HID to equip over 200,000 items with RFID tags to track them. RFID technology enables the quick identification and tracking of objects, which increases the efficiency of work processes. Passive RFID tags can be applied to the surface of equipment and read from a distance of up to ten meters. The identification number of the item being searched for is retrieved via a software system. A handheld reader acts as a kind of Geiger counter and provides feedback when approached. Several RFID tags can be read simultaneously, even if the objects are packed in containers.

As a result, process efficiency has increased considerably. A process that used to take two and a half hours with two employees can now be completed by one person in just 15 minutes. This has made the process 95 percent more efficient. With stationary readers or RFID gates, the check-in process for rental equipment can also be reduced from 22 minutes to 10 seconds. The result: a time saving of 99.24 percent.

The use of RFID tags on rental objects makes product identification much easier. US film equipment rental company Rentex, for example, has worked with HID to equip over 200,000 items with RFID tags to track them. RFID technology enables the quick identification and tracking of objects, which increases the efficiency of work processes. Passive RFID tags can be applied to the surface of equipment and read from a distance of up to ten meters. The identification number of the item being searched for is retrieved via a software system. A handheld reader acts as a kind of Geiger counter and provides feedback when approached. Several RFID tags can be read simultaneously, even if the objects are packed in containers.

As a result, process efficiency has increased considerably. A process that used to take two and a half hours with two employees can now be completed by one person in just 15 minutes. This has made the process 95 percent more efficient. With stationary readers or RFID gates, the check-in process for rental equipment can also be reduced from 22 minutes to 10 seconds. The result: a time saving of 99.24 percent.

“With barcode, assembling the kit is very time consuming. Some pieces of equipment are heavy and manipulating them for clear line of sight is cumbersome. Finding exactly the right kind of cable of the correct length also usually took a very long time.”

Richard Aufreiter

VP Product Marketing

Injection Moulding Tools from Hasco with a Digital ID

Hasco has been labeling two-stage ejectors with RFID tags from production since 2023. These enable optimized process design in mould making worldwide. The 8 millimeter RFID tag turns the two-stage ejector into a digital and smart component. With the introduction of RFID mold tags from Neosid, Hasco offers its customers a digital option for forgery-proof identification of products, as well as quick access to relevant product information. The solution therefore is also used as a counterfeit protection measure.

Access to important data such as 3D models, installation and maintenance instructions as well as technical limit values is granted. The Hasco app confirms the originality of the products when the tag is scanned. This is done using an NFC-enabled smartphone or an RFID reader. The unique identifier (UID) consists of 64 bits and enables authenticity verification and traceability. This ensures that the customer receives the guaranteed quality, service and warranty.

Hasco has been labeling two-stage ejectors with RFID tags from production since 2023. These enable optimized process design in mould making worldwide. The 8 millimeter RFID tag turns the two-stage ejector into a digital and smart component. With the introduction of RFID mold tags from Neosid, Hasco offers its customers a digital option for forgery-proof identification of products, as well as quick access to relevant product information. The solution therefore is also used as a counterfeit protection measure.

Access to important data such as 3D models, installation and maintenance instructions as well as technical limit values is granted. The Hasco app confirms the originality of the products when the tag is scanned. This is done using an NFC-enabled smartphone or an RFID reader. The unique identifier (UID) consists of 64 bits and enables authenticity verification and traceability. This ensures that the customer receives the guaranteed quality, service and warranty.

"Our aim is to always be one step ahead of the curve and to offer innovative solutions for injection molds. Hasco's portfolio now includes more than 100,000 different components. All of them are designed for plastics processing industries, toolmaking and injection molding shops."

Andre Brandt

Executive Vice President Mould Base Technology

RFID RTLS at Hull University Teaching Hospital

At Hull University Teaching Hospitals NHS Trust, a large hospital in England, a cloud-based solution enables the tracking of medical equipment. Over 72,000 items have already been tagged with passive RFID tags. In addition, 2,700 sterile trays are tagged every week. 640 stationary RFID readers and over 400 antennas have already been installed at two large hospital sites. 320 mobile computers from Zebra Technologies enable the tracking of assets and patient items. The main objective of the asset management solution is to reduce the search time for medical equipment.

The result: The RFID solution reduces staff search times from 4 hours to 4 minutes.

At Hull University Teaching Hospitals NHS Trust, a large hospital in England, a cloud-based solution enables the tracking of medical equipment. Over 72,000 items have already been tagged with passive RFID tags. In addition, 2,700 sterile trays are tagged every week. 640 stationary RFID readers and over 400 antennas have already been installed at two large hospital sites. 320 mobile computers from Zebra Technologies enable the tracking of assets and patient items. The main objective of the asset management solution is to reduce the search time for medical equipment.

The result: The RFID solution reduces staff search times from 4 hours to 4 minutes.

"In our opinion, this is the largest deployment of RFID in healthcare for real-time asset location tracking in Europe. It is certainly the most complex. We are already seeing improvements in patient care as well as huge time savings and a reduction in procurement costs."

Rachael Ellis

Scan4Safety Program Director

Smart Asset Management Stories

IT is the Driving Force Behind Asset Management

In the context of asset management, information technology (IT) acts as the core engine that drives and optimizes the entire process. IT offers a comprehensive range of tools and platforms that make it possible to efficiently capture, monitor, analyze, and manage assets. Through the use of databases, sensors, and analytics technologies, IT can provide a comprehensive real-time overview of the condition, scope, and location of assets.

In addition, IT enables the automation of routine tasks, resulting in increased productivity and reduced operating costs. By integrating machine learning and artificial intelligence (AI) in companies, advanced analytical models can be developed to provide predictive maintenance capabilities and optimized decision support. Overall, IT acts as a driving force that enables organizations to modernize existing asset management to generate benefits and operate more sustainably.

Synergies Through Connecting IT and Assets

Advantages of Wireless IoT

- Precise monitoring of assets

- Extensive asset data records

- Real-time localization of assets

- Maintenance history of the assets

- Cost savings

Physical assets are connected to digital IT systems. The result: comprehensive data sets are created that enable precise monitoring, localization, analysis, and control of assets in real time. This paradigm shift in the management of fixed assets promises to increase efficiency in all branches of industry.

Why? Because there are advantages: Resources are optimally utilized, predictive maintenance and servicing run more efficiently, inventories achieve results at the push of a button, and strategic decisions are more informed based on data analysis. Stock levels are monitored closely, digitalized supply chains are managed more efficiently, and bottlenecks are identified more quickly. The real-time monitoring and tracking of assets also enables a faster response to losses, theft, or unauthorized movements.

An example of this is printer asset management (PAM). PAM is a module of an IT asset management software that enables companies to manage printer fleets. With PAM, companies are provided with an overview of printings costs, and can plan, monitor, and automate printing processes.

The synergy between IoT and asset management opens up potential for proactive and data-driven operational management that can even replace traditional asset management models. As a highlight, IoT in asset management also enables the development of new business models. Artificial intelligence (AI), big data, and machine learning can help to analyze large amounts of data, identify patterns, and make predictions. In asset management, for example, they can be used for risk assessment and process automation.

Physical assets are connected to digital IT systems. The result: comprehensive data sets are created that enable precise monitoring, localization, analysis, and control of assets in real time. This paradigm shift in the management of fixed assets promises to increase efficiency in all branches of industry.

Why? Because there are advantages: Resources are optimally utilized, predictive maintenance and servicing run more efficiently, inventories achieve results at the push of a button, and strategic decisions are more informed based on data analysis. Stock levels are monitored closely, digitalized supply chains are managed more efficiently, and bottlenecks are identified more quickly. The real-time monitoring and tracking of assets also enables a faster response to losses, theft, or unauthorized movements.

An example of this is printer asset management (PAM). PAM is a module of an IT asset management software that enables companies to manage printer fleets. With PAM, companies are provided with an overview of printings costs, and can plan, monitor, and automate printing processes.

The synergy between IoT and asset management opens up potential for proactive and data-driven operational management that can even replace traditional asset management models. As a highlight, IoT in asset management also enables the development of new business models. Artificial intelligence (AI), big data, and machine learning can help to analyze large amounts of data, identify patterns, and make predictions. In asset management, for example, they can be used for risk assessment and process automation.

Advantages of Wireless IoT

- Precise monitoring of assets

- Extensive asset data records

- Real-time localization of assets

- Maintenance history of the assets

- Cost savings

Integrated Facility Management and Asset Management

The combination of facility management and asset management is crucial for the efficient management and optimization of company resources. By integrating these two areas, companies can comprehensively monitor, maintain, and manage their plants and facilities. This leads to improved transparency, an optimized use of resources and a reduction in operating costs. The close integration of facility management and asset management thus ensures smooth and cost-efficient operation.

Challenges: Asset Types and Cyber Attacks

One challenge lies in the complexity and heterogeneity of asset types, which makes uniform and consistent management difficult. Furthermore, limited resources, both financial and human, as well as structural requirements, can pose a challenge, especially with regard to the implementation of modern technologies.

Another challenge is ensuring data management, security, and integrity, particularly with regard to the increasing digitalization and networking of assets. The risks associated with cyberattacks and data loss require a proactive security strategy and suitable protective measures.

Trusted Partners

Suppliers for Asset Management Solutions

Next-Level Asset Management

A range of IT tools will increasingly optimize asset management in the future. Asset Performance Management (APM), for example, is a holistic approach to maximizing the performance and value of assets in an industrial context.

Other trends include the integration of RTLS solutions and systems for predictive maintenance and servicing.

Asset Performance Management (APM)

The goal of APM is to optimize asset life and availability by implementing preventive maintenance strategies based on continuous monitoring and analysis. By integrating data from various sources, including sensors, historical data sets, and operational data, APM can accurately assess the current condition of assets and predict potential failures.

Based on these insights, precautionary decisions can be made to optimize maintenance, minimize downtime, and maximize asset efficiency. APM incorporates a variety of technologies and methods, including data analytics, machine learning, and artificial intelligence.

Maintenance and Predictive Maintenance

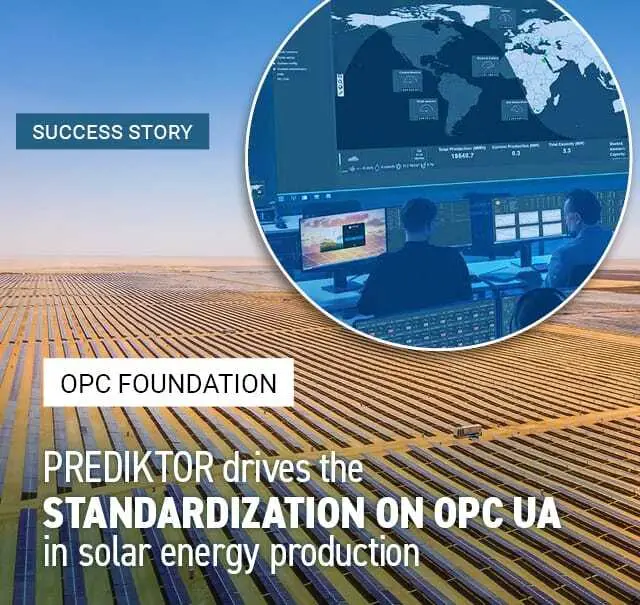

Predictive maintenance and asset management are closely linked. Predictive maintenance is an advanced method of asset management based on data-driven analysis to predict potential asset failures and initiate preventive maintenance measures.

By integrating sensor technology, data analysis and machine learning, predictive maintenance enables early detection of deviations in the operating behavior of assets before they lead to serious malfunctions. This predictive approach aims to minimize unplanned downtime, maximize uptime, and optimize asset efficiency. By analyzing historical operational data and real-time information, accurate models can be developed to predict future performance and asset condition.

Based on these forecasts, maintenance activities can be better planned. This reduces costs and increases plant availability. In addition, predictive maintenance enables a gradual shift from time-based or condition-based maintenance strategies to a demand-oriented approach based on the actual needs of the assets. Overall, the integration of predictive maintenance into asset management offers companies the opportunity to optimize operations and increase competitiveness by focusing on preventive and data-driven maintenance practices.

Real-Time Localization

The integration of RTLS with BLE, RFID, or UWB technology in the management of goods generates a variety of benefits. Real-time localization enables the continuous monitoring and capture of real-time data. This way, companies can achieve a more accurate inventory management and resource utilization. The ability to remotely monitor and control goods that can be located enables faster response to changes in demand and optimized supply chain management.

-13-3-25-responsive.webp)