Extreme Temperature Fluctuations Between Storage and Analysis

Automated Sample Handling

Richard Aufreiter, VP Product Marketing, Identification Technologies, HID Global.

The samples are stored in analysis tubes at negative 196 degrees Celsius. Examinations and tests are partly carried out at room temperature. The temperature fluctuations are enormous and components used, such as sample containers and sample holders, must withstand more than 500 cycles in individual cases.

The increasing number of samples per year presented EMBL with the decision to develop an automated sample handling system in 2018. A new sample holder standard in combination with a robot allows testing the growing number of samples without additional manual effort.

Richard Aufreiter explains why the use of RFID tags is the best performing solution to ensure that not a single sample is lost in the automated process due to a missing tag:

The samples are stored in analysis tubes at negative 196 degrees Celsius. Examinations and tests are partly carried out at room temperature. The temperature fluctuations are enormous and components used, such as sample containers and sample holders, must withstand more than 500 cycles in individual cases.

The increasing number of samples per year presented EMBL with the decision to develop an automated sample handling system in 2018. A new sample holder standard in combination with a robot allows testing the growing number of samples without additional manual effort.

Richard Aufreiter explains why the use of RFID tags is the best performing solution to ensure that not a single sample is lost in the automated process due to a missing tag:

Richard Aufreiter, VP Product Marketing, Identification Technologies, HID Global.

"In the test series with more than 200,000 samples per year, RFID technology is essential for efficient and correct handling. The transponders withstand the extreme conditions such as cryogenic temperatures and high temperature fluctuations. HID's Piccolino tags manage the technological balance between smallest design and highest possible robustness. This results in safe and reproducible processes in the laboratory."

Not a Single Sample is Lost Due to a Missing Tag

200,000 Crystalline Samples Evaluated Annually

Inside the Synchrotron – the radiation beamline is the thin silver pipe.

With the objective of researching active ingredients for new pharmaceutical medicines, the European Molecular Biology Laboratory (EMBL) processes more than 200,000 crystalline samples per year. The samples are stored at almost negative 200 degrees Celsius and continuously analyzed in several test series in an electron synchrotron at room temperature.

The sample handling is highly automated and supported by robots. Continuous identification during the test series is ensured by labeling the sample holders with cryo-resistant HF RFID tags.

With the objective of researching active ingredients for new pharmaceutical medicines, the European Molecular Biology Laboratory (EMBL) processes more than 200,000 crystalline samples per year. The samples are stored at almost negative 200 degrees Celsius and continuously analyzed in several test series in an electron synchrotron at room temperature.

The sample handling is highly automated and supported by robots. Continuous identification during the test series is ensured by labeling the sample holders with cryo-resistant HF RFID tags.

Inside the Synchrotron – the radiation beamline is the thin silver pipe.

HF RFID Near Absolute Zero

Patented Method Creates Permanent Connection of Antenna and IC

Sample holder (Puck) being inserted in the probe storage container. Only six millimeters in diameter are available for inserting the tags into the sample holders. EMBL is currently using customized 'Piccolino' tags from HID Global.

HF RFID tags from HID Global are the key element in the highly automated, robot-assisted sample handling processes.

"Not every RFID chip works permanently with consistent performance under these temperature conditions. Unsuitable materials can break, for example," reports Richard Aufreiter.

"The transponder used for permanent identification of the sample holders had to be as robust as possible, but also particularly small. Only six millimeters in diameter are available for inserting the tags into the sample holders."

EMBL is currently using customized 'Piccolino' tags from HID in the sample holders. The tags are manufactured using the patented process, in which the IC is connected directly to the antenna.

"An additional module for connection is not necessary. At the same time, the patented bonding process increases the robustness of the tags."

HF RFID tags from HID Global are the key element in the highly automated, robot-assisted sample handling processes.

"Not every RFID chip works permanently with consistent performance under these temperature conditions. Unsuitable materials can break, for example," reports Richard Aufreiter.

"The transponder used for permanent identification of the sample holders had to be as robust as possible, but also particularly small. Only six millimeters in diameter are available for inserting the tags into the sample holders."

EMBL is currently using customized 'Piccolino' tags from HID in the sample holders. The tags are manufactured using the patented process, in which the IC is connected directly to the antenna.

"An additional module for connection is not necessary. At the same time, the patented bonding process increases the robustness of the tags."

Sample holder (Puck) being inserted in the probe storage container. Only six millimeters in diameter are available for inserting the tags into the sample holders. EMBL is currently using customized 'Piccolino' tags from HID Global.

Robots Realize Highly Automated Sample Handling

1. Model of the Test Chamber with X-Ray Beamline Entering the Room from the Right

The X-ray tube (beamline - on the right) of the ESRF (European Synchrotron Radiation Facility) produces a focused X-ray beam about 100 billion times brighter than an X-ray machine in a hospital, creating a "shadow image" of the molecules of the sample crystal.

The X-ray tube (beamline - on the right) of the ESRF (European Synchrotron Radiation Facility) produces a focused X-ray beam about 100 billion times brighter than an X-ray machine in a hospital, creating a "shadow image" of the molecules of the sample crystal.

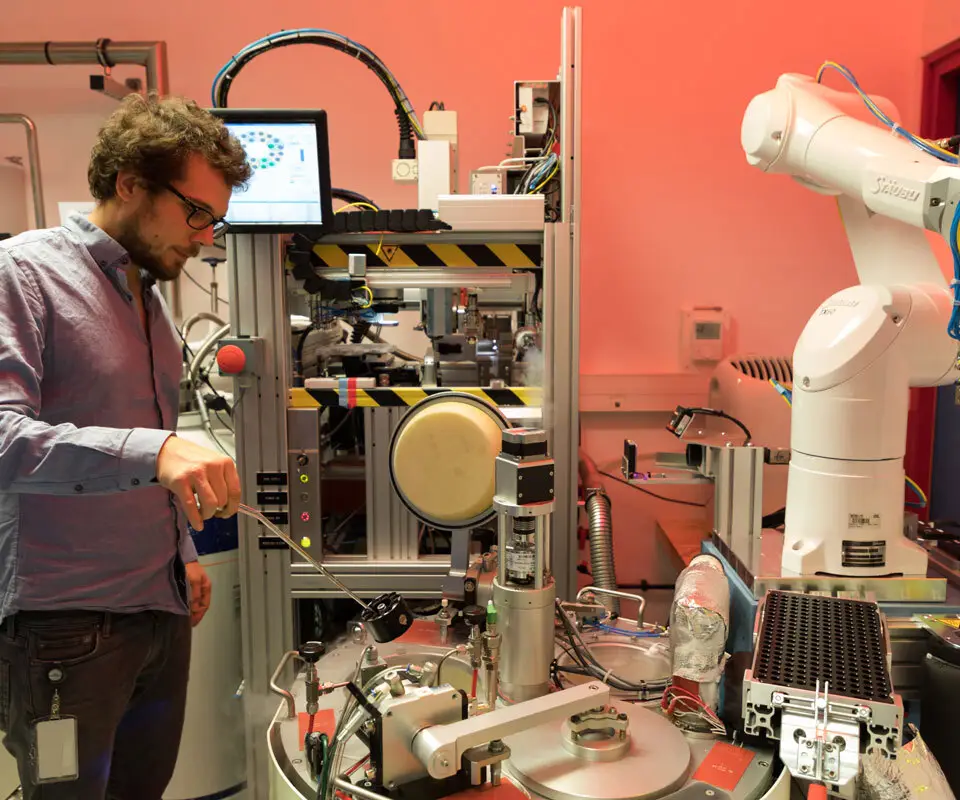

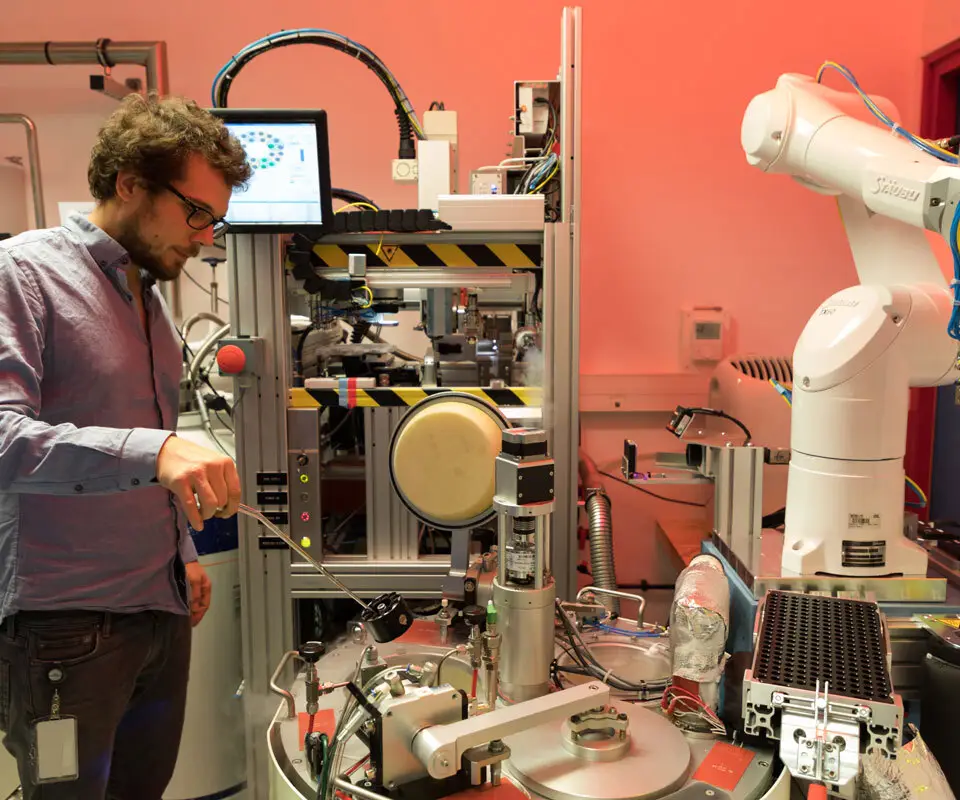

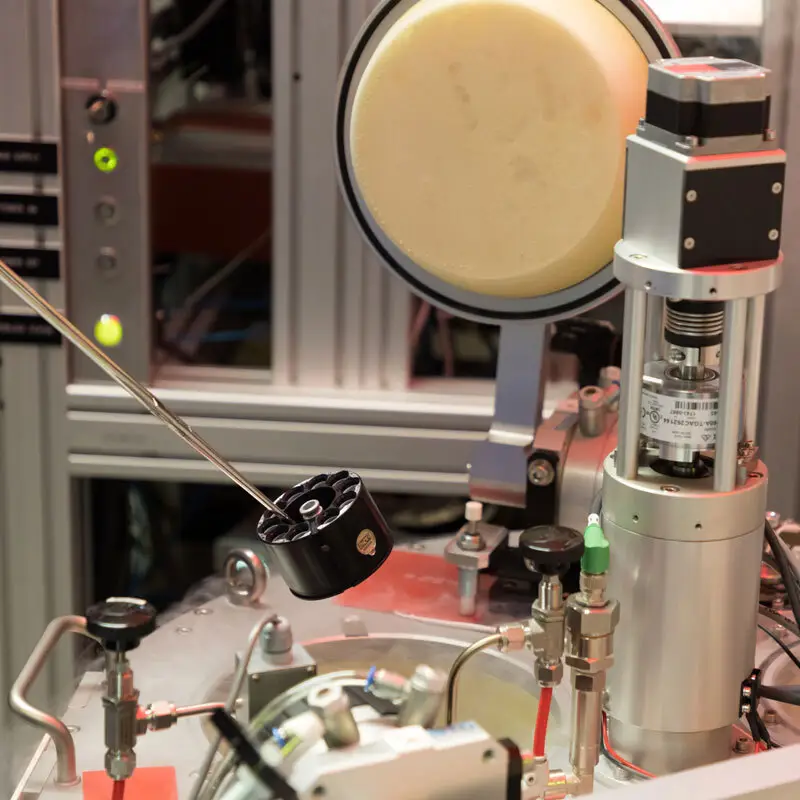

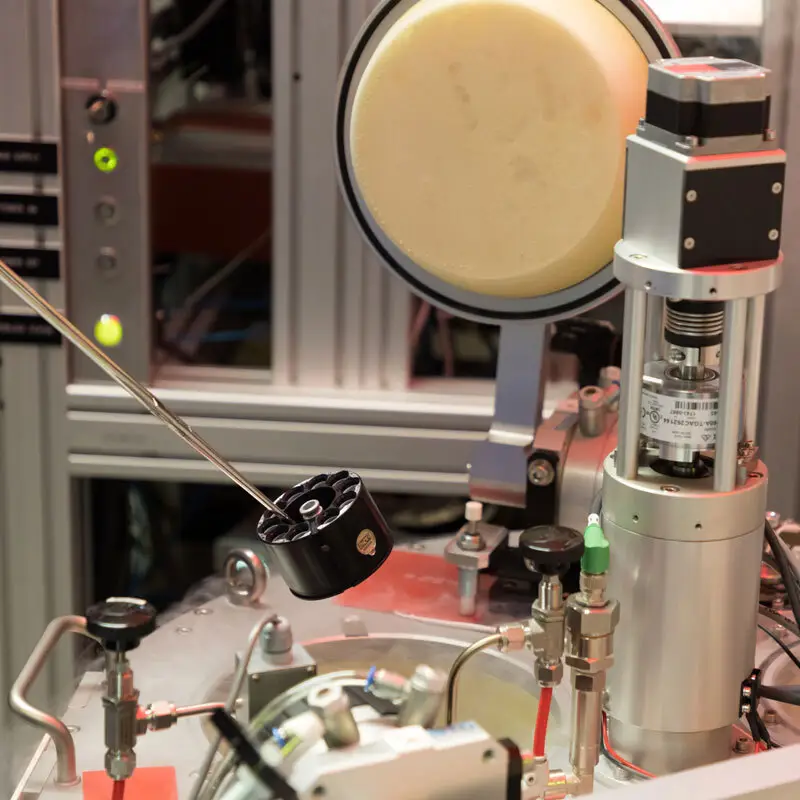

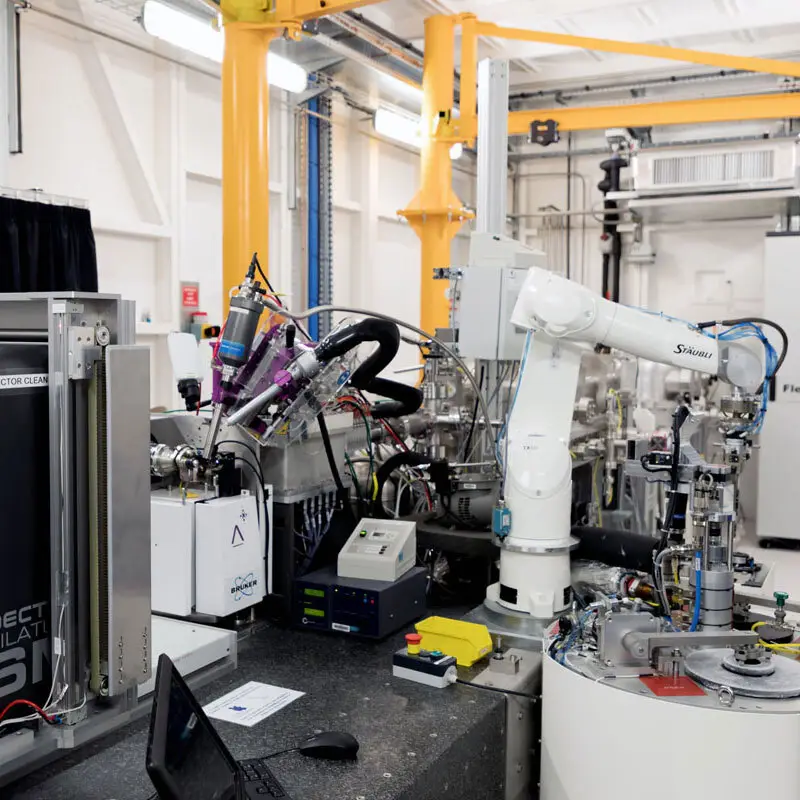

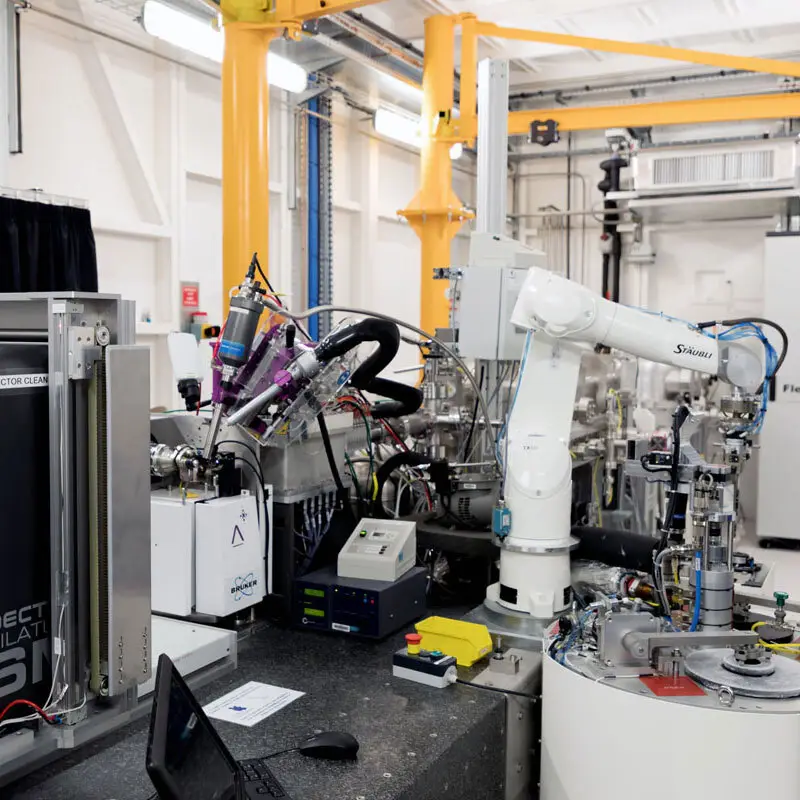

2. Probe Storage Container and Sample Handling Robot

Up to 200,000 sample crystals are evaluated in the laboratory per year. Automated handling increases throughput and helps to avoid human error.

Up to 200,000 sample crystals are evaluated in the laboratory per year. Automated handling increases throughput and helps to avoid human error.

3. Sample Holder (Puck) Being Inserted in the Probe Storage Container

Up to 10 sample crystals are stored together in cylindrical containers called "pucks" for convenient handling and storage. For clear identification, these are provided with cryo-resistant RFID tags.

Up to 10 sample crystals are stored together in cylindrical containers called "pucks" for convenient handling and storage. For clear identification, these are provided with cryo-resistant RFID tags.

4. Puck with Samples in Liquid Nitrogen

In liquid nitrogen at -196 °C (-321 °F), the grown sample crystals are stored frozen until analysis. Several pucks are stored together in one container, making identification via RFID important here as well.

In liquid nitrogen at -196 °C (-321 °F), the grown sample crystals are stored frozen until analysis. Several pucks are stored together in one container, making identification via RFID important here as well.

5. Puck with Samples in Reader

A puck with samples outside the cryo-container.

A puck with samples outside the cryo-container.

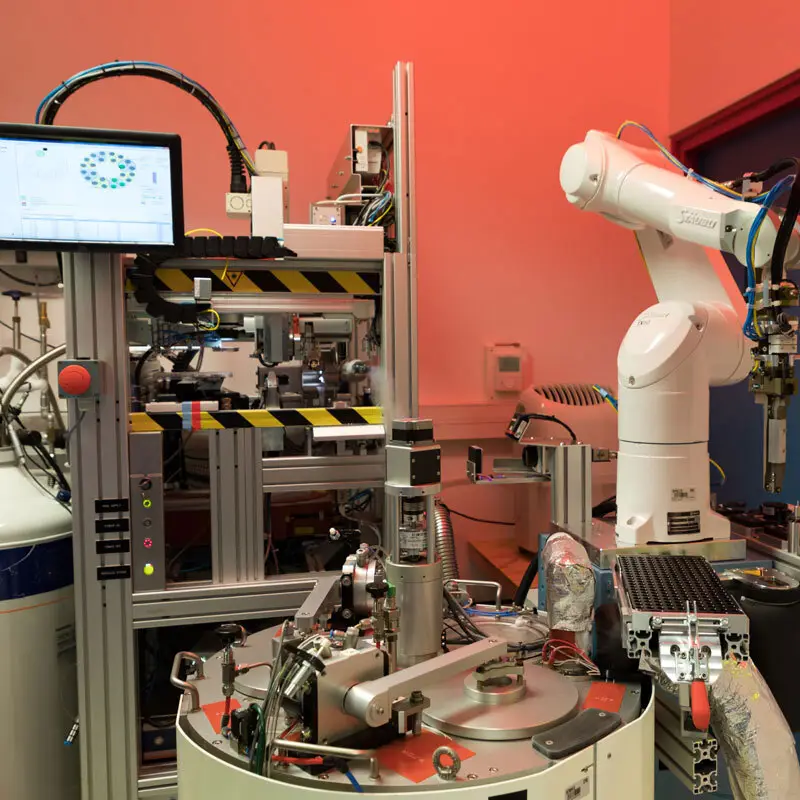

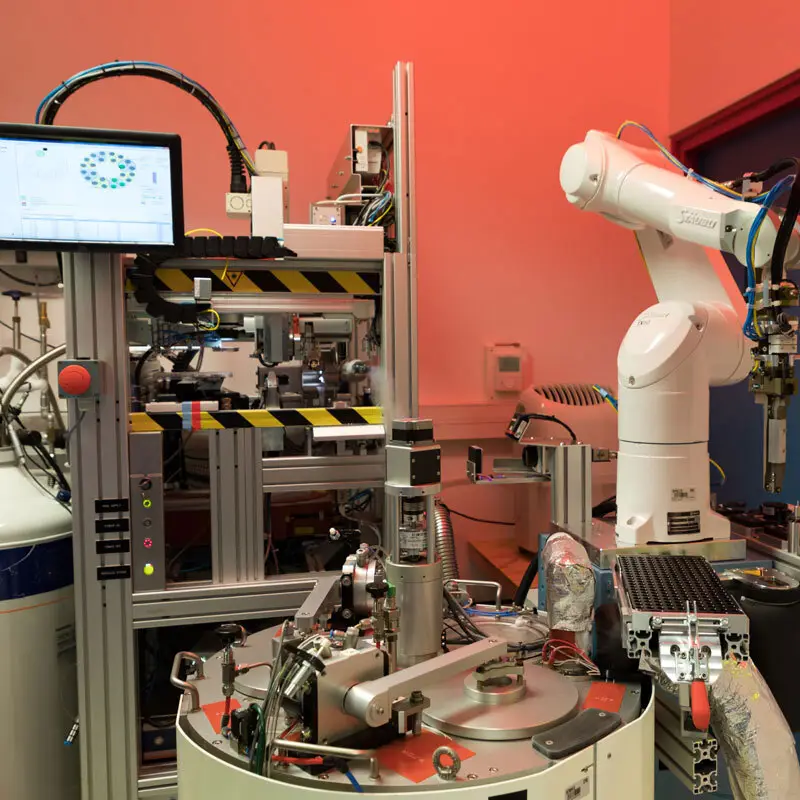

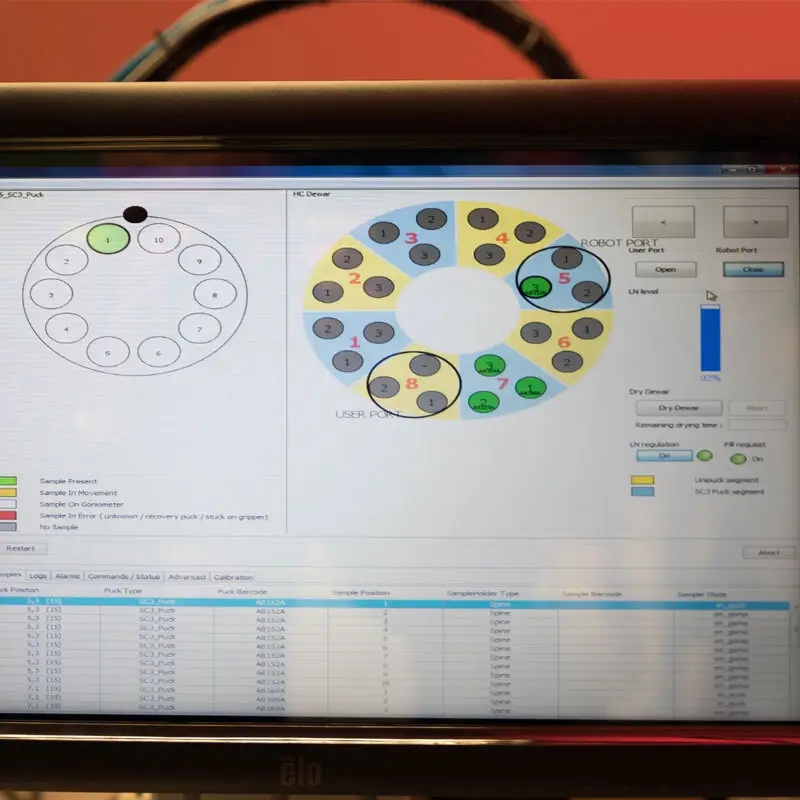

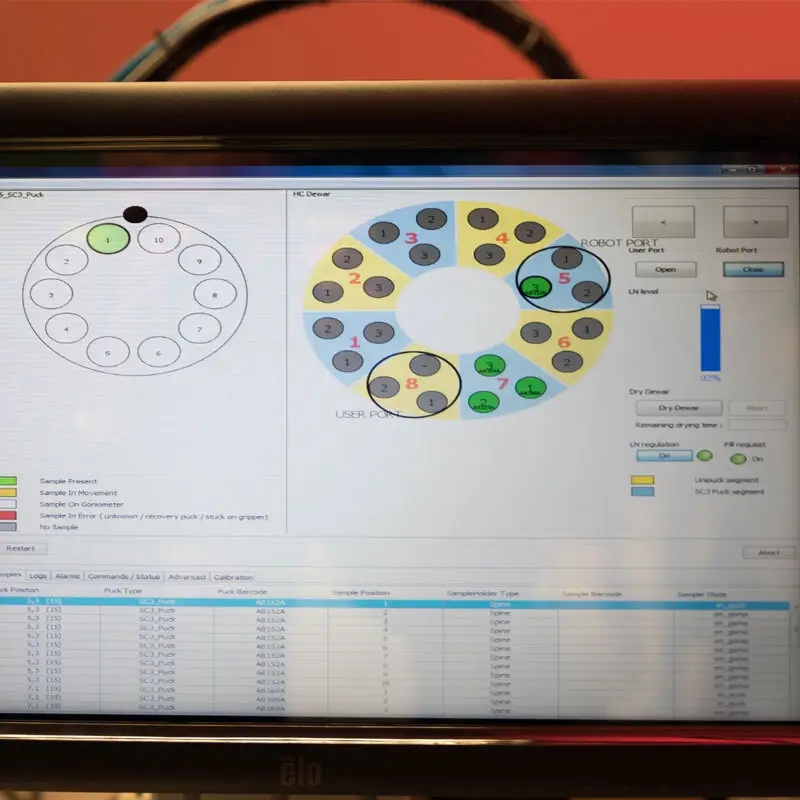

6. Screenshot of a Sample Positioning System Robot

The robot identifies the individual samples in the puck fully automatically and can also insert them into or remove them from the analyzer.

The robot identifies the individual samples in the puck fully automatically and can also insert them into or remove them from the analyzer.

7. Imaging Chamber with Detector, Probe Holder and Sample Handling Robot (FLTR)

The robot takes the desired sample from the cryo container (right) and places it with precision into the cooled sample attachment (left) on which the sample is then targeted with the X-ray beam and the molecular image generated in the detector.

The robot takes the desired sample from the cryo container (right) and places it with precision into the cooled sample attachment (left) on which the sample is then targeted with the X-ray beam and the molecular image generated in the detector.

8. Crystal Probe Fixation in Front of the Beamline Exit

The sample crystal, which is analyzed with the X-ray beam of the synchrotron, sits on the small pin (at the bottom of the image), barely visible to humans.

The sample crystal, which is analyzed with the X-ray beam of the synchrotron, sits on the small pin (at the bottom of the image), barely visible to humans.

-über-Wi-Fi-HaLow-400.webp)

-über-Wi-Fi-HaLow-responsive.webp)