Automated Logistics

The term logistics can be found in almost every professional analysis by experts, as all processes in our economic life are impacted by logistical movements.

The official definition of logistics varies depending on the context. Most scientific studies are based on the definition of the Council of Supply Chain Management Professionals (CSCMP). This is an organization that is primarily concerned with supply chain management. The CSCMP's definition of logistics is as follows: "Logistics management is the part of supply chain management that plans, implements, and controls the efficient and effective forward and reverse movement and storage of goods, services, and related information between the point of origin and the point of consumption to meet the requirements of customers or businesses."

The definition emphasizes the importance of logistics for planning, implementing, managing, and controlling the movement and storage of goods and information to meet the needs of customers and business. It also makes it clear that logistics cannot be viewed as an isolated concept, but is seen as an integral part of overall supply chain management.

In Germany, the term "intralogistics" was coined specifically for this purpose. Intralogistics was introduced in Germany around the turn of the millennium, i.e. towards the end of the 1990s. Intralogistics encompasses the internal logistics of companies, i.e. all logistics processes that take place within a plant or warehouse, such as incoming and outgoing goods.

Different Sub-Sectors of Logistics and Their Tasks

The logistics industry plays an essential role in the efficient movement, storage, and handling of goods, and is therefore an important part of the global economy. Without logistics, the economy would grind to a halt. The most important sub-sectors of logistics are listed below to illustrate which sub-sectors are included and how they differ.

The following section also illustrates that all sub-sectors are closely interrelated and complement each other. This illustrates the relevance of big data solutions in logistics. In order to create digital twins of warehouses or to optimize the logistics cold chain with artificial intelligence, it is essential to integrate cloud computing and the Internet of Things (IoT) into all future planning. In general, quality assurance in logistics aims to strengthen or expand the position of companies.

Conclusion: The sectors presented illustrate the complexity and diversity of the logistics industry and its crucial role in the organization of global supply chains.

- Procurement Logistics comprises the procurement of raw materials and goods required for production or direct sales. This involves selecting suppliers, clarifying key procurement data and organizing the physical procurement and logistics of materials.

- Production Logistics comprises the processes relating to resources, production control, and material flows within a production company. Its aim is to make the production process as efficient as possible in order to achieve the production targets. Production logistics works closely with procurement logistics, as production depends on the correct supply of raw materials. Otherwise, the production lines come to a standstill.

- Distribution Logistics is responsible for the distribution of finished products to end consumers or retailers. This includes warehousing, warehouse management, asset management, container management, load carrier management, transportation management, order processing, and the selection of distribution channels.

- Warehouse Logistics is a sub-sector of distribution logistics and focuses on the efficient storage of goods, the organization of the warehouse, and the optimization of warehouse processes. This also includes the implementation of warehouse management systems. Real-time localization solutions or indoor positioning systems are frequently used in the warehouse sector.

- Transport Logistics is a sector that, alongside logistics, is also part of the "traffic and transportation" industry. It includes all activities related to the physical transportation of goods, whether by road, rail, air, or water. This includes the organization, execution, and monitoring of transport routes, goods, and transport operations. The real-time localization of load carriers, bins, or containers also plays a crucial role in this logistics sector.

- Transshipment Logistics is aimed at the loading, unloading, and onward transportation of goods, often using transshipment terminals such as ports, marshalling yards, or airports. The distances are short, which is why AGVs or conveyor systems are often used. For this reason, the optimal planning of the processes is required to avoid costly delays in loading or unloading, time-consuming searches, or traffic jams in onward transportation.

- Disposal Logistics involves the logistics surrounding the disposal and recycling of materials and products. The collection, transportation, processing, and disposal of waste are the core processes of waste disposal logistics. In the future, level measurements on waste containers will enable demand-oriented control of waste disposal logistics, which can save costs and CO2.

- Reverse Logistics involves the return of products and materials from the end user back to the manufacturer or to a special disposal center. This often takes place as part of recycling programs or for reprocessing. Returns management is also part of this. This is an area that requires a lot of effort in e-commerce and will need to be more strictly regulated in the future in order to achieve sustainability goals.

- Information Logistics is the IT infrastructure for all operational processes. This is where the efficient management and transmission of information required to control physical logistics flows takes place. The use of IT systems such as SCM (supply chain management) software should also be mentioned in this context. One of the sections below explains software solutions in logistics in more detail.

Logistics Including Liability and Warranty

Contract logistics is a special form of logistics, as it covers almost all areas of logistics and is carried out on behalf of a customer. The services are therefore comprehensive and individually tailored to the respective customer. Contract logistics includes procurement, transport, fulfillment, storage, distribution, and returns.

In general, contract logistics is a business model within the logistics industry in which a company (the client) commissions a logistics service provider for the comprehensive and long-term handling of its logistics processes. The services go beyond pure transportation or storage, and encompass a wide range of activities. Depending on the agreement, liability and warranty may also be included.

Due to the complexity of the processes that a contract logistics provider is responsible for in the context of contract logistics, the use of monitoring technologies that provide data in real time is of great importance. In contract logistics in particular, the quality of performance for the customer and the customer's trust in the contract logistics provider are crucial.

Contract logistics comprises a variety of tasks that can be divided into five main areas:

- Warehousing and inventory management

- Picking and packing

- Transport management

- Returns management

- Value-added services (assembly of products)

One of the advantages for the client is that by outsourcing these tasks to a specialized service provider, the company can focus on its core competencies. It can also benefit from the expertise and existing networks of the logistics partner. Furthermore, cost benefits can often be observed through economies of scale and the optimization of the entire supply chain. The collaboration is usually based on long-term contracts that guarantee a customized service including warranty and liability.

Wireless IoT Technologies in Intralogistics

Intralogistics refers to all logistical processes within a company that focus on the flow of materials, goods, and information within storage or production facilities. The term therefore stands for logistics processes for which a company is responsible, and which take place within a closed cycle and are spatially limited. The essential aspects and activities include warehouse management and inventory management to ensure the proper storage and availability of products. Picking and packing also play an important role, as they involve compiling orders according to customer requirements and packing the goods for dispatch.

Incoming and outgoing goods are checked and logged, while outgoing products are loaded and dispatched. Material flow management plans and controls the movement of materials within the production facilities. Conveyor technology, such as conveyor belts, automated transport systems, and cranes, enables the movement of materials.

Warehouse technology and warehouse management uses shelving systems, robotics, and software to manage the warehouse. Automation plays another important role by using autonomous vehicles, robotics, and other automated systems to increase efficiency. Efficient returns management involves organizing the return, reprocessing, and disposal of unsold or defective goods.

IT systems such as warehouse management systems (WMS) and enterprise resource planning systems (ERP) are used to track, control, and optimize internal logistics. Quality control ensures that the stored and transported goods are checked for quality through inspections and monitoring systems.

Safety and environmental management ensures compliance with safety regulations and the reduction of waste and energy consumption. Employee planning and management are crucial for the organization of human resources and the planning of work processes.

Wireless systems based on IoT are becoming increasingly important in intralogistics as they increase efficiency, optimize material flow, and improve transparency. Some of the most important technologies used in this area are presented below.

- Intralogistics systems often use Wi-Fi for fast and reliable data transmission, especially in warehouses, where they connect mobile devices, warehouse management software, and machine control systems.

- For precise location tracking within warehouses or production facilities, Bluetooth LE or UWB technology is often used for asset tracking, indoor navigation and the localization of goods, machines, or devices.

- RFID is often used in intralogistics to record information on the basis of passive or active tags that are attached to goods, containers, or load carriers. The tags are read by wireless RFID readers to quickly capture information such as product location, condition, or status. If goods and devices need to be tracked over longer distances, for example in extensive warehouse and production environments, LoRaWAN or NB-IoT are used. Both LPWAN technologies offer the connection of sensors, are suitable for long distances, and have advantages due to their energy efficiency.

- Zigbee is a wireless mesh network protocol for monitoring sensors and controlling automated processes. It is particularly suitable for networked devices that need to communicate with each other over short distances.

Automation Technology in Logistics

Products Designed for the Logistics Sector

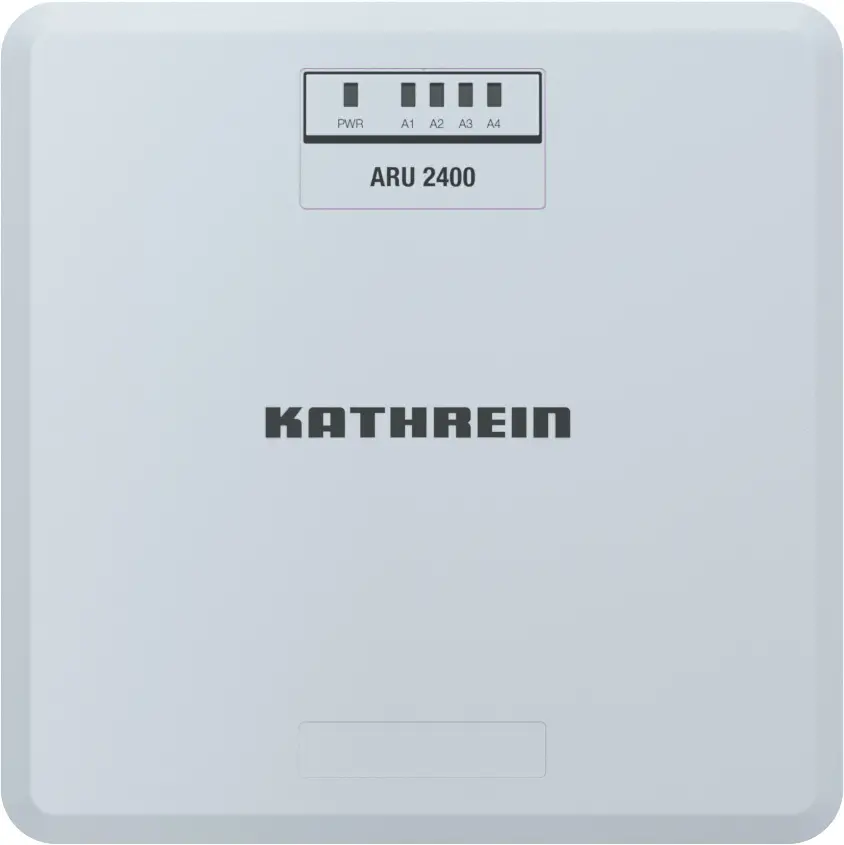

Numerous products are used in the logistics industry with the aim of increasing efficiency, optimizing supply chains, and improving transparency. Among the products actively used are RFID read/write devices, which enable the individual tracking of goods or assets via RFID tags attached to products and pallets, and ensure fast detection and localization in the warehouse or during transport. Bluetooth LE and LoRaWAN gateways play an important role: While Bluetooth LE is used for precise location determination in warehouses for indoor navigation and asset tracking, LoRaWAN's long range and low energy requirements make it ideal for tracking over long distances, for example in container logistics, container management, or when monitoring vehicle fleets

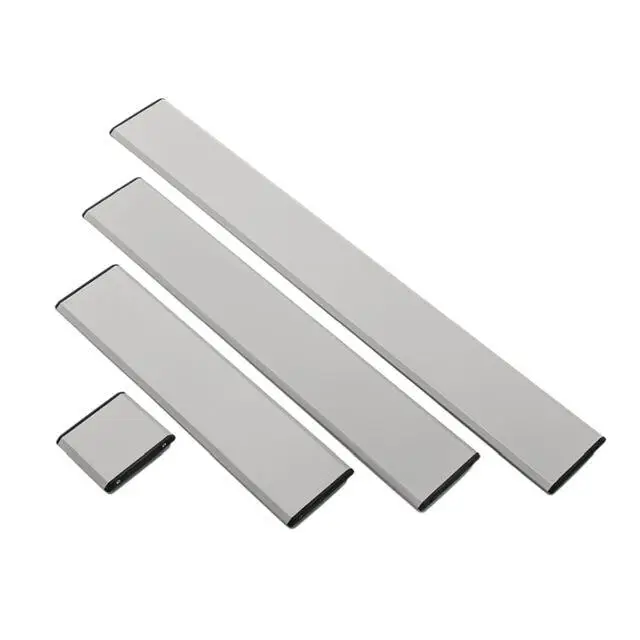

Scanners are another indispensable tool in logistics. They can be used to quickly and accurately capture goods entering and leaving the warehouse. Advanced systems also use image recognition technologies to check the condition of goods. Antennas, on the other hand, are a core component of RFID tracking systems, as they capture the signals of RFID tags and thus determine the position of goods in real time. Surveillance cameras contribute to the security and monitoring of storage and operating areas. Intelligent camera systems can also carry out automated checks and sorting of goods.

Labels and transponders are essential for tracking and stock taking. This is especially the case with RFID and barcode labels, which serve as the basis for these systems in logistics. Special label printers print the necessary barcode and RFID labels for product identification. GPS trackers make it possible to track transport vehicles in real time, which is particularly important for international deliveries. Finally, logistics software also plays a crucial role in the modern supply chain. This includes warehouse management systems (WMS), transport management systems (TMS), supply chain management software (SCM), and route optimization systems.

Logistics Automation to Grow by Almost 15 Percent Between 2023 and 2030

According to a report by LM Ericsson, the number of IoT connections in the transportation sector will increase from 100 million in 2020 to 292 million in 2030. The COVID-19 pandemic has accelerated the adoption of IoT technologies in logistics, with IoT, automation and robotics playing a central role in monitoring shipments and vehicles. The integration of cloud-based application interfaces has taken hold, enabling seamless connectivity to e-commerce platforms, which has been used by 90 percent of logistics companies surveyed in response to the pandemic, in order to accelerate IoT implementation and drive market recovery.

Another report by ‘Grand View Research’ predicts that the global market for automation in logistics will grow by almost 15 percent between 2023 and 2030. Logistics automation includes hardware and software solutions that aim to optimize processes such as transportation, warehousing, retrieval, and data management to increase efficiency, reduce errors, and shorten lead times. These technology solutions support the scalability of companies by efficiently managing larger volumes with the help of autonomous robots, conveyor systems, autonomous driverless vehicles, and automated warehouse systems.

Advances and Technological Innovations in Logistics

Intralogistics is on the verge of a profound change, which is being driven to a large extent by the use of innovative wireless solutions. These technological advances are not only helping to reduce costs, but are also revolutionizing the way logistics processes are carried out.

With the advent of self-driving vehicles in warehouses, the question arises as to how they can operate autonomously. The answer lies in the integration of AI systems and advanced sensor technologies that enable the vehicles to orient themselves independently in the warehouse and carry out tasks efficiently. Robots that replace warehouse employees are no longer a vision, but a reality. They work faster, with fewer errors, and can be deployed around the clock, which significantly increases productivity.

The introduction of smart clothing for warehouse employees with 5G network connectivity and an integrated display optimizes communication and processes in the warehouse. Such innovations enable employees to work more efficiently while always being informed about important information. Another forward-looking innovation is self-organizing pallets that are controlled by IoT technologies and enable autonomous warehousing.

At the supply chain level, wireless solutions enable demand-oriented and stable operations even in times of crisis. By using real-time data and networked systems, companies can react quickly to changes and adapt their supply chains.

Sustainability for companies and the reduction of CO2 emissions are also coming into focus. Advances in electromobility and improved logistics routes are helping to reduce emissions on the road and in the air. Increased rail transport is another approach to minimizing environmental impact and increasing efficiency at the same time.

Asset management and container management are reaching the next level through the use of intelligent technologies. The tracking and management of goods is becoming more precise, leading to optimized processes and fewer losses. Load carrier and pallet management also benefits from these technologies, making the entire logistics process more efficient.

Pool systems could be the future, especially in terms of sustainability and cost efficiency. These systems enable flexible use of resources and reduce unnecessary redundancies and investments.

In summary, wireless solutions in intralogistics not only help to reduce costs, but also to increase efficiency, reduce environmental impact, and to improve the resilience of supply chains. These technologies are fundamentally changing the logistics landscape and opening up new avenues for innovation and progress.

RFID for Pallet Tracking in the Warehouse

An RFID-based pallet tracking solution has been introduced in the warehouse of KEB Automation. The load carriers are identified via RFID tags with a unique handling unit (HU) number. This number is stored in SAP Extended Warehouse Management (EWM). The picked pallets are made available in the warehouse for the automated guided vehicles (AGVs). 20 Q5X sensors from Turck detect the presence of the pallets during transportation to the production halls. The sensors are installed at the transfer points.

As soon as a pallet is detected, a transport order is generated for the AGV. The DTS picks up the pallet and transports it through an RFID gate. Each pallet with an RFID transponder is detected by external antennas at the hall gates with a read rate of almost 100 percent. These antennas are connected to a Q300 UHF RFID reader. The load can be identified regardless of the position of the pallet.

An RFID-based pallet tracking solution has been introduced in the warehouse of KEB Automation. The load carriers are identified via RFID tags with a unique handling unit (HU) number. This number is stored in SAP Extended Warehouse Management (EWM). The picked pallets are made available in the warehouse for the automated guided vehicles (AGVs). 20 Q5X sensors from Turck detect the presence of the pallets during transportation to the production halls. The sensors are installed at the transfer points.

As soon as a pallet is detected, a transport order is generated for the AGV. The DTS picks up the pallet and transports it through an RFID gate. Each pallet with an RFID transponder is detected by external antennas at the hall gates with a read rate of almost 100 percent. These antennas are connected to a Q300 UHF RFID reader. The load can be identified regardless of the position of the pallet.

"By using this RFID solution, we can deliberately allow a certain amount of chaos here in order to be able to work efficiently. As soon as a pallet leaves the area, the pallet and its destination are automatically detected."

Phillip Hannesen

Digital Transformation Manager for Produktion

Tracking Wool Bales with UHF RFID

From July 2023, all new wool parcels in Australia have been fitted with an RFID eBale tag to track the wool bales throughout the supply chain. The Australian Wool Exchange (AWEX) has introduced the RFID system in collaboration with HID. The eBale tags are resistant to temperature, chemicals, pressure, and torsion. Equipped with an RFID chip and a QR code, each eBale tag has a unique number. This gives each bale of wool a unique identity.

The data on the eBale tags is captured using RFID readers. The data is recorded using the WoolClip program and transmitted to warehouses, logistics and transport centers, sales representatives, and national and international processing centers.

From July 2023, all new wool parcels in Australia have been fitted with an RFID eBale tag to track the wool bales throughout the supply chain. The Australian Wool Exchange (AWEX) has introduced the RFID system in collaboration with HID. The eBale tags are resistant to temperature, chemicals, pressure, and torsion. Equipped with an RFID chip and a QR code, each eBale tag has a unique number. This gives each bale of wool a unique identity.

The data on the eBale tags is captured using RFID readers. The data is recorded using the WoolClip program and transmitted to warehouses, logistics and transport centers, sales representatives, and national and international processing centers.

"With HID's support, AWEX was able to identify a UHF transponder capable of surviving the harsh conditions of the wool supply chain and apply it to wool packaging. The result is commercially available eBales and the world's first nationwide rollout of RFID technology for wool packaging."

Mark Grave

CEO

Wine Logistics Optimized with RFID

The wine producer Symington Family Estates optimizes its internal logistics processes with RFID. Since 2015, semi-finished products have been equipped with hybrid barcode and RFID labels. During the wine bottling process, two labels with GS1-128 barcodes and RFID SSCC-96 are printed. These labels are affixed to metal load carriers that carry around 600 bottles. Around 5,000 load carriers with RFID labels are in circulation every year.

All incoming goods are recorded in the ERP system after filling. The load carriers are then transported to the warehouse. The entrance gate to the warehouse is equipped with an RFID reader. When passing the RFID reader, the information from the RFID transponder, including the location, the load unit ID or SSCC (Serial Shipping Container Code), and the time zone, is sent to the ERP system in accordance with the EPCIS standard. In this way, the RFID transponders enable the load carriers to be tracked in real time.

When the semi-finished product reaches the finishing line for labeling and packaging, two RFID readers along the production lines read the RFID transponder. This enables seamless control and monitoring of the internal process chain and guarantees the exact completion of the product with the corresponding label.

The wine producer Symington Family Estates optimizes its internal logistics processes with RFID. Since 2015, semi-finished products have been equipped with hybrid barcode and RFID labels. During the wine bottling process, two labels with GS1-128 barcodes and RFID SSCC-96 are printed. These labels are affixed to metal load carriers that carry around 600 bottles. Around 5,000 load carriers with RFID labels are in circulation every year.

All incoming goods are recorded in the ERP system after filling. The load carriers are then transported to the warehouse. The entrance gate to the warehouse is equipped with an RFID reader. When passing the RFID reader, the information from the RFID transponder, including the location, the load unit ID or SSCC (Serial Shipping Container Code), and the time zone, is sent to the ERP system in accordance with the EPCIS standard. In this way, the RFID transponders enable the load carriers to be tracked in real time.

When the semi-finished product reaches the finishing line for labeling and packaging, two RFID readers along the production lines read the RFID transponder. This enables seamless control and monitoring of the internal process chain and guarantees the exact completion of the product with the corresponding label.

"The ultimate goal was to be one step ahead of future supply chain requirements. The dynamics within the supply chain are increasingly changing. An increasing number of companies are investing in the digital transformation and standardization of the supply chain. When we switched to RFID in 2015, we also wanted to reduce inventory times."

Isabel Freitas

Analyst Developer

More Articles on IoT in Logistics

What Influence Do Robots Have on the Work of People?

At a time when robots are increasingly being used in the world of work, employees remain as the most valuable asset of a stable company. Even if automated systems take over many processes, it is the expertise and innovative strength of people that ensure the long-term success of a company. Therefore, training employees to become IT specialists and skilled workers is crucial. This training ensures that the workforce can keep pace with technological developments and use them effectively.

In this context, the educational activities of governments are particularly important. A proactive education policy that promotes both technical skills and critical thinking skills is crucial for social and economic development. Innovation should not only take place in the technology sector. It is equally important that it also brings about social changes that benefit everyone.

By going beyond what is purely technological and also aiming for positive social change, innovations can create a more inclusive and fairer society. This requires a rethinking of the way education and labor market policies are designed to keep pace not only with the technological, but also the social challenges of our time.

Internet of Things in Logistics

The Internet of Things (IoT) is revolutionizing the logistics industry and driving digitalization in the logistics sector. By networking devices and systems, IoT enables seamless communication and data transmission, leading to a more efficient and transparent logistics chain. Automated transport systems are an essential part of this development. They enable the automation of warehouse processes and the use of driverless transport systems that transport goods precisely and without human intervention.

Another significant advancement is autonomous driving in logistics. By using self-driving trucks, transportation tasks can be carried out in a safer and more efficient manner while reducing operating costs. These vehicles use advanced sensors and artificial intelligence to navigate safely through traffic while collecting real-time data.

Big data in the transport sector makes it possible to analyze large volumes of data and gain valuable insights. This data helps companies optimize their supply chains by identifying trends and patterns that human analysts may not notice. Cloud computing in transportation provides the necessary infrastructure to securely store and process this data, while allowing access to this information from anywhere, at any time.

Artificial intelligence in the transportation sector plays a crucial role in improving the efficiency and predictability of supply chains. AI-supported systems can optimize routes, reduce fuel consumption, and plan vehicle maintenance in advance to minimize downtime.

One specific area in which IoT is particularly useful is cold chain transportation. This involves the transportation of temperature-sensitive goods such as food and medicine. IoT sensors continuously monitor the temperature and other environmental conditions to ensure that the goods remain in optimum condition.

E-learning in the transportation sector provides employees with access to important training and education. By using digital platforms, logistics companies can ensure that their employees are always up to date with the latest technology and best practices.

Telematics in transportation combines GPS technology with onboard diagnostic systems to provide real-time data on vehicle location, speed, and condition. This information is critical for monitoring and controlling transportation fleets and helps to improve the safety and efficiency of logistics operations.

Overall, the Internet of Things has fundamentally changed the logistics industry. By integrating IoT technologies, companies can optimize their processes, reduce operating costs, and increase customer satisfaction at the same time. The ongoing digitalization of the logistics industry will continue to bring new opportunities and challenges that can be mastered through innovative technologies and intelligent solutions.

Software Controls All Logistics Processes

The logistics industry would be inconceivable without software. It increases the efficiency of processes, improves transparency, and optimizes the entire supply chain. The most important purposes and IT solutions used in this area are presented below:

- Transport Management Systems (TMS) help with the planning, execution and optimization of transports. Freight cost management enables precise calculation and invoicing of transportation costs.

- Route optimization ensures the most efficient routing and optimizes vehicle utilization.

- Warehouse Management Systems (WMS) control and optimize warehouse processes such as picking, storage, and retrieval, as well as inventory management. Automatic Identification and Data Capture (AIDC) facilitates permanent stock taking and goods tracking with RFID or barcode technology.

- Supply chain management (SCM) systems coordinate the entire flow of goods along the supply chain. This also includes demand and inventory planning, which can be used to forecast future requirements and optimize stock levels.

- Enterprise resource planning (ERP) systems integrate logistics processes with other areas such as purchasing, sales, and production.

- Fleet management software monitors the status, location, and condition of vehicles. Fleet management also includes telematics systems that provide real-time data for accurate vehicle tracking and maintenance planning.

- Order Management Systems (OMS) are assigned to the sector of e-commerce and customer satisfaction. They manage online orders and provide real-time status information. Track-and-trace software is a service that allows customers to track their orders.

- Returns management systems simplify the processing of returns and increase customer satisfaction.

- Business intelligence tools analyze logistics data and support strategic decisions. Artificial intelligence (AI) in companies and machine learning support the optimization of processes and forecasts.

Partners Spezialized in Logistics Solutions

Energy Reduction and the Carbon Footprint Will Become Increasingly Important in the Future

In logistics, the integration and use of wireless IoT technologies leads to significant improvements in many aspects of management and operations. These technologies enable comprehensive optimization of warehouse management and logistics processes, leading not only to an increase in efficiency, but also to a reduction in CO2 emissions, energy consumption, and other operating costs.

The use of smart glasses in logistics centers is revolutionizing the warehouse management process. Employees can call up augmented reality-supported information directly in their field of vision, which significantly speeds up and simplifies order picking and container management. This contributes to a reduction in warehouse space and working capital, as more efficient work processes require less space and resources.

Remote e-learning and a more dynamic design of training programs for logistics employees can also be brought to the same level using smart glasses. Interactive and realistic training scenarios help to make the complexity of logistics processes tangible and promote process optimization through better trained personnel.

Telematics plays a crucial role in optimizing fleet management. By using IoT devices in vehicles, real-time data can be transmitted that not only improves route planning, but also enables fuel savings. These technologies also help to make vehicle maintenance more efficient and minimize downtime.

Asset management, in particular the management of load carriers and pallets, as well as the use of pool systems, is made considerably easier by IoT. Sensors and RFID tags enable seamless tracking and control of logistics resources, which optimizes recycling and returns management and ultimately leads to further cost savings.

In addition, the use of machine vision in logistics enables automated monitoring and analysis of stock levels and shipments. This technology improves inventory accuracy and enables proactive maintenance of warehouse equipment, which in turn leads to a reduction in warehouse space and energy savings.

The integration of these wireless IoT technologies into the logistics of smart cities expands the potential of urban logistics systems. By better connecting and automating urban logistics infrastructure, supply chains can be made more efficient and urban transportation systems can be relieved, contributing to a significant overall reduction in CO2 emissions.

Autonomous vehicles in the logistics sector can operate almost 24 hours a day, shortening delivery times, and increasing productivity. Fuel consumption and maintenance costs are reduced through optimized driving modes.

Computer vision in logistics can be used to automate warehouse management by recognizing, sorting, and tracking items, improving the accuracy and speed of warehouse operations. Visual inspection systems allow products to be checked quickly and accurately for defects or damage.

Visions for Logistics

Big data in transport plays a crucial role here, as the analysis of large volumes of data from various sources enables more precise planning and control of traffic flows. This data helps logistics companies avoid bottlenecks, increase efficiency and shorten delivery times.

Logistics cloud computing provides the necessary infrastructure to store this data securely and make it accessible in real time. By using cloud services, logistics companies can react flexibly to changing market requirements and scale their IT resources efficiently. Artificial intelligence in transport is increasingly being used to automate and optimize complex logistics processes. AI-supported systems analyze data, make well-founded decisions and adapt dynamically to new situations, thereby optimizing the entire logistics chain.

Machine learning in logistics offers the possibility of recognizing patterns in historical data and deriving predictions for future events. This technology is used to forecast demand, manage inventories and optimize routes. An innovative approach is Pick by RFID, which uses radio frequency identification technology to improve the picking process. By automatically identifying and tracking goods, errors are reduced and efficiency is increased.

Predictive maintenance in logistics uses data analysis and machine learning to continuously monitor the condition of vehicles and equipment and identify maintenance requirements at an early stage. This prevents unexpected breakdowns and reduces maintenance costs. Geofencing in logistics makes it possible to set virtual geographical boundaries in order to monitor the movements of vehicles and goods in real time. This technology helps to heighten security and ensure compliance with regulations.

Telematics systems in logistics combine GPS technology with various sensors and communication systems to provide detailed information about the location, movement, and condition of vehicles. These systems are crucial for fleet management and the optimization of transport processes.

The visions for logistics are characterized by end-to-end digitalization and networking, which enables a more efficient, secure and flexible logistics chain. Through the use of big data, cloud computing, artificial intelligence, machine learning, RFID, predictive maintenance, geofencing, and telematics systems, the logistics industry will be able to meet the challenges of the future while opening up new opportunities. These technologies will help to increase customer satisfaction, reduce operating costs, and promote sustainability in logistics.

-über-Wi-Fi-HaLow-400.webp)