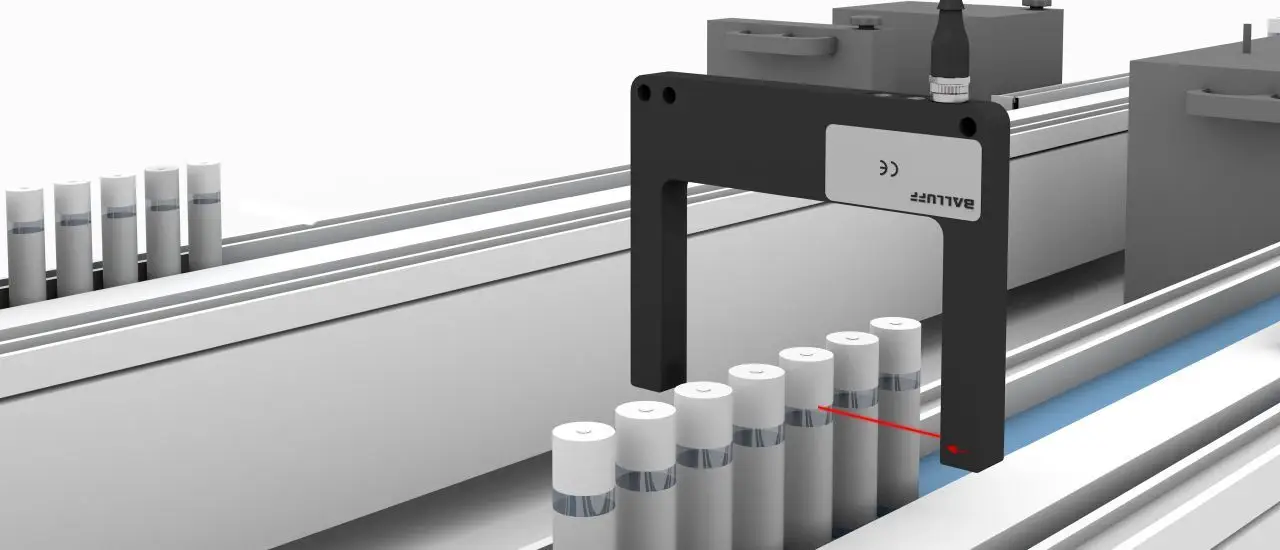

Versatile and reliable: New BGL fork light barriers from Balluff

Florian Hermle

Managing Director

"We improve our customers' competitiveness by accompanying them long-term in their business processes and opening up new perspectives through our passion for automation. With our comprehensive portfolio of high-quality sensor, identification, and image processing solutions as well as software, we offer holistic solutions, connecting OT with IT and guiding our customers step by step to the smart factory."

Global Leader with Industry-Proven RFID LF, HF, UHF Solutions

With more than 6 years of experience in industrial automation and over 40 years of competence in the area of RFID, Balluff is a committed partner with industry proven LF, HF and UHF solutions for rough environments. The product portfolio includes stationary and mobile read / write devices, controllers, antennas, and transponders.

Our Product Portfolio Includes:

Balluff Automation Solutions for Efficient Intralogistics

Product Cluster Manager Identification

Events

Livestream on Wireless IoT in Healthcare. Livestream delayed – new schedule coming soon.

Date

June 11th 2025

Location

Online

International Exhibition | Think WIoT Conference

Date

22-23 October 2025

Location

Wiesbaden, Germany