Interview with Yilmaz Benzer

Yilmaz Benzer is Managing Director of Neosid.

1. RFID in dental technology: What are the advantages?

There are over 1,200 dental practices in Germany with many different tools such as mouth mirrors, tweezers and drills that need to be managed efficiently. RFID transponders can be integrated into these tools to make management easier. RFID-supported systems help to ensure precise tool selection and error prevention. Individual settings such as speed and feed rate can minimize wear and increase efficiency. Tool life monitoring enables timely maintenance.

2. How can the construction industry benefit from RFID integration?

RFID enables digital construction processes. RFID tags can be used to simplify the tracking of building materials and equipment. This facilitates tool and component tracking as well as construction inspections and maintenance. Accessible information on raw materials, material stocks, construction progress and usage increases transparency. Overall, RFID integration increases productivity, reduces costs and improves efficiency in the construction industry.

1. RFID in dental technology: What are the advantages?

There are over 1,200 dental practices in Germany with many different tools such as mouth mirrors, tweezers and drills that need to be managed efficiently. RFID transponders can be integrated into these tools to make management easier. RFID-supported systems help to ensure precise tool selection and error prevention. Individual settings such as speed and feed rate can minimize wear and increase efficiency. Tool life monitoring enables timely maintenance.

2. How can the construction industry benefit from RFID integration?

RFID enables digital construction processes. RFID tags can be used to simplify the tracking of building materials and equipment. This facilitates tool and component tracking as well as construction inspections and maintenance. Accessible information on raw materials, material stocks, construction progress and usage increases transparency. Overall, RFID integration increases productivity, reduces costs and improves efficiency in the construction industry.

Yilmaz Benzer is Managing Director of Neosid.

RFID for Identification and Traceability

Neosid

- Manufacturer of ferrite components, inductors, and RFID antennas and transponders

- Customers: End users in healthcare, industry, logistics, and more

- Products: Ferrite and antenna development for RFID transponder and reader solutions

- Solutions: Asset management and tracking, traceability, labeling & identification

3. How does RFID support the legal requirements for load handling and slinging equipment?

The maintenance and maintenance documentation of load handling attachments and slings are required by law in accordance with DGUV Rule 109-017 and DIN 685-5. RFID transponders in the lifting equipment allow the required data to be collected easily, consistently and securely. Maintenance processes are logged and the information can be read quickly and securely using an external reader. In addition, the use of RFID enables quick identification and traceability of the equipment, which enables efficient documentation and tracking in the event of inspections or accidents.

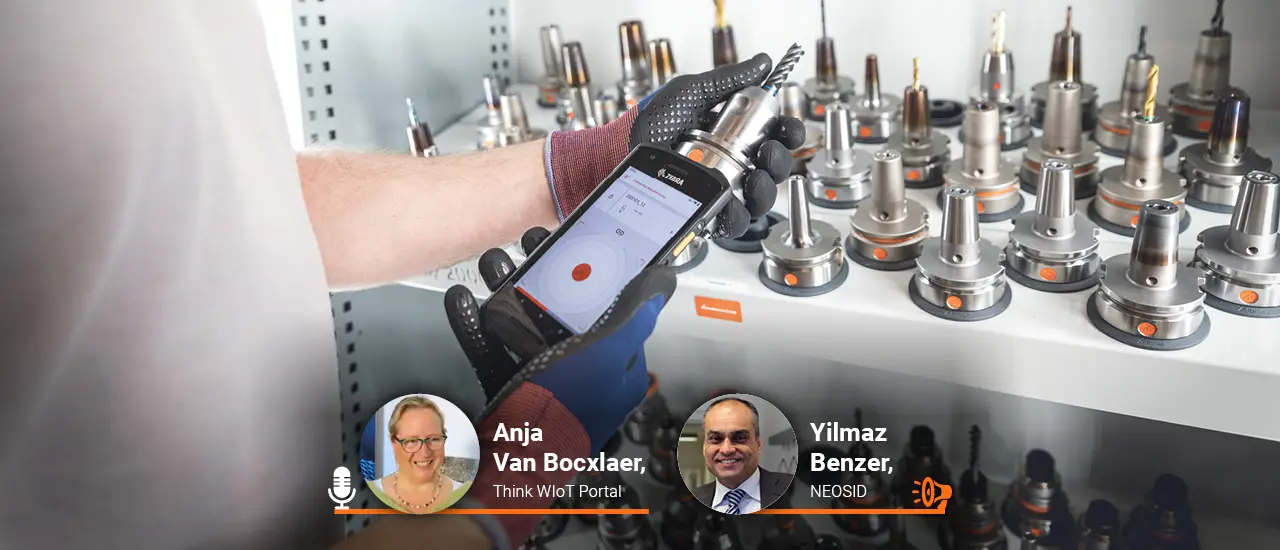

4. What role does RFID technology play in tool management?

RFID offers a more efficient solution for tool management compared to optical identification. It speeds up tool search and setup, minimizes errors and reduces the risk of machine damage. In conjunction with suitable software, RFID also enables secure and digitized production. In 2019, for example, the Hoffmann Group used our RFID transponders in combination with the "Connected Manufacturing" software for tool identification.

3. How does RFID support the legal requirements for load handling and slinging equipment?

The maintenance and maintenance documentation of load handling attachments and slings are required by law in accordance with DGUV Rule 109-017 and DIN 685-5. RFID transponders in the lifting equipment allow the required data to be collected easily, consistently and securely. Maintenance processes are logged and the information can be read quickly and securely using an external reader. In addition, the use of RFID enables quick identification and traceability of the equipment, which enables efficient documentation and tracking in the event of inspections or accidents.

4. What role does RFID technology play in tool management?

RFID offers a more efficient solution for tool management compared to optical identification. It speeds up tool search and setup, minimizes errors and reduces the risk of machine damage. In conjunction with suitable software, RFID also enables secure and digitized production. In 2019, for example, the Hoffmann Group used our RFID transponders in combination with the "Connected Manufacturing" software for tool identification.

Neosid

- Manufacturer of ferrite components, inductors, and RFID antennas and transponders

- Customers: End users in healthcare, industry, logistics, and more

- Products: Ferrite and antenna development for RFID transponder and reader solutions

- Solutions: Asset management and tracking, traceability, labeling & identification

-über-Wi-Fi-HaLow-400.webp)

-über-Wi-Fi-HaLow-responsive.webp)