The Use of BIM and IoT Technologies

The results of a study by ‘McGraw Hill Construction’ show that 97 percent of Japanese construction companies that use Building Information Modeling (BIM) achieve a positive return on investment (ROI). Benefits include a 21 percent increase in project estimating accuracy, 23 percent more efficient waste management, a 31 percent reduction in rework, and a 41 percent reduction in error rates.

The Asia-Pacific region, led by China's robust infrastructure and manufacturing sector, is cited as a major player in the IoT construction market in the same report by ‘Allied Market Research’. An estimated 83 percent of contractors see the potential of wearable IoT technologies to improve safety on construction sites and to reduce fatal injuries.

Overall, the IoT market in the construction industry is expected to grow significantly. According to a report by ‘Stellar Market Research’, this sector will grow from 11.42 billion USD in 2023 to 32.29 billion USD in 2030, almost tripling in size. Key players such as Alice Tech, IBM Corp. and Caterpillar play an important role in this growth. ‘Allied Market Research’ forecasts even higher growth. According to the report, the market value of the IoT construction industry is expected to reach 44.2 billion USD by 2031.

The Construction Industry is Complex – Which Sub-Sectors are Included?

The construction industry comprises a large number of sub-sectors that deal with the planning, actual construction, renovation, and operation of buildings and infrastructure projects. When it comes to digitalization for companies in the construction industry, it makes sense to connect to the Internet of Things (IoT) and integrate wireless IoT solutions.

Construction Planning

Before the groundbreaking ceremony takes place, the architects' concept work begins. This includes not only the design of the building and its statics, but also schedules, resource planning, and the application for the construction permit. For larger projects such as airports, tunnels, or building complexes, construction plan management and overall project control are crucial to the success of the construction project and adherence to the schedule. Construction planning encompasses the entire management and control of the construction project, including the monitoring of all trades, the coordination and scheduling of work, and the procurement of resources. Managing big data in construction projects is a very important task.

Structural Construction

By structural construction we mean the construction of buildings. These can be individual residential buildings, as well as multi-unit dwellings, or office buildings. It also includes the construction of commercial buildings, hotels, or apartment blocks. Projects in structural construction primarily concern space for living or working. The majority of these buildings are located above ground level. Towers are also included.

Civil Engineering

In contrast to structural construction, civil engineering deals with projects below the ground line. This includes projects such as road construction, sewer construction, water and wastewater infrastructure, and tunnel construction. It also includes bridge construction, railroad construction, and the construction of dams. These construction projects are characterized by the fact that they involve a very high proportion of earthworks.

Structural Engineering

This sub-area of civil engineering deals with extensive and complex structures and large construction sites, such as power plants, airports, container ports, oil refineries, or other industrial plants. This area of the construction industry benefits greatly from the digitalization of individual construction processes. Digitization secures the control, management, quality management, and schedule of the construction project.

Ancillary Building Trades

This sub-sector is also referred to as the finishing trade. It includes trades that are involved in the entire finishing of construction projects. These include, for example, floor and screed layers, plasterers, painters, electricians, glaziers, joiners, and carpenters.

Digitalization in the Construction Industry

Digitalization strategies are therefore primarily used for quality assurance in the construction industry, the networking of different project teams, the transparent transfer of information, and ultimately the conservation of resources and budgets. The digitalization of the construction industry is based on IT tools and wireless IoT hardware for the identification of construction vehicles, tools, components, and materials.

The interaction of software and hardware generates efficiency, productivity, and safety for the entire construction project. The digitalization of the construction industry is therefore an important market. For companies in the construction industry, the digitalization of processes can represent a competitive advantage, as they are able to monitor, control, and document process flows.

Wireless radio-based systems in particular, is significantly changing processes in the construction industry. Radio-frequency identification (RFID)-based networking of construction equipment, machines, or components in the construction industry enables sensors to send status data and locations directly to IoT platforms. This networking of equipment on construction sites allows construction companies to influence the distribution of materials or machines in real time. Machine deployment can be significantly optimized.

Overall, the use of wireless IoT technologies significantly improves the monitoring and analysis of processes in the construction industry. If components are equipped with sensors, it is even possible to use these data carriers as information carriers even after the component has been installed. The information on the component can play an important role in the context of maintenance or settlement claims.

One IT tool that supports digitalization is Building Information Modeling (BIM). BMI can be used to digitally represent buildings or structures. This includes geometric data, building materials, costs, schedules, and also operating instructions or information on maintenance and servicing. BIM ensures better collaboration between project participants and optimizes planning steps throughout the entire construction process.

Wireless IoT Technologies Used in the Construction Industry

Products Designed for the Construction Industry

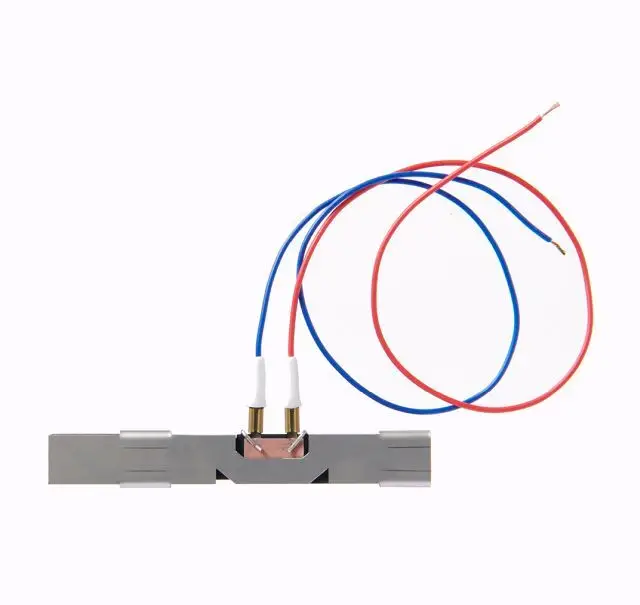

Bluetooth LE sensors are installed on assets or construction machinery to locate and monitor the condition of these assets, indoors and outdoors, in real time. These industrial beacons track the location of assets and people with optional sensors to capture environmental data. Construction site monitoring systems use these wireless sensors and networks to monitor construction sites. In this way, temperature, humidity, air quality, and even noise levels can be monitored to improve working conditions. Construction companies can also use sensors and RFID transponders to track the health and use of their machines, tools, and assets. This monitoring enables efficient resource planning. In addition, theft can be reduced and the maintenance and servicing of equipment can be optimized. This field of application is geared towards tools and equipment. In turn, the control of construction machinery can be optimized via CBS and telematics. Another technology for locating construction machinery on construction sites is the integration of LoRaWAN sensors and gateways. In cooperation with experts, construction companies can determine the optimal IoT technologies and hardware components for their machines, equipment, and building materials. Overall, the range of sensors and transponders based on a wide variety of technologies and the associated read/write devices, gateways, or handhelds is extensive. Depending on the field of application (indoors or outdoors), ambient temperature and the desired identification range, as well as the degree of resistance and robustness, different systems can even be combined with each other. Innovative wireless IoT products in the construction industry include data glasses and robotics. These will transform work areas in the construction industry in the long term.

Wireless IoT Application Areas in the Construction Industry

The areas of application in the construction industry are just as diverse as the sub-sectors of the construction industry and the available wireless IoT technologies. The following examples show that the spectrum can range from asset tracking and the condition monitoring of assets to the predictive maintenance and servicing of machinery. When it comes to safety, wireless IoT technologies can optimize both the work safety of employees on the construction site and the safety of buildings.

For example, the strength of concrete can be measured to determine exactly whether the installed material was processed at the right time. Other areas of application for digitalization in the construction industry include the supply of components and sustainability for companies. The more resource-efficient construction processes are, and the fewer transportation routes are used, the lower the CO2 emissions.

Identification and Localization of Windows with RFID

Toro Aluminum, a Canadian supplier of windows and doors for high-rise buildings, has been using UHF RFID to identify prefabricated aluminum components since 2023. More than 3,000 components are produced every week. The aluminum profiles are cut to size using CNC machines. RFID printers integrated into the CNC machines generate coded RFID tags with production data such as dimensions. These are linked to the ERP system. The aluminum profiles are then assembled on one of 10 assembly lines, each equipped with two RFID ceiling antennas from Feig Electronic. Once the ID of the component has been captured by the antennas, assembly begins.

In some cases, the windows must be temporarily stored in a holding or quarantine warehouse before being transported to the final assembly and inspection location. Ceiling-mounted antennas enable the localization of all windows in the warehouse in real time. Information about the location of each component and the duration of storage is stored in the ERP system.

Toro Aluminum, a Canadian supplier of windows and doors for high-rise buildings, has been using UHF RFID to identify prefabricated aluminum components since 2023. More than 3,000 components are produced every week. The aluminum profiles are cut to size using CNC machines. RFID printers integrated into the CNC machines generate coded RFID tags with production data such as dimensions. These are linked to the ERP system. The aluminum profiles are then assembled on one of 10 assembly lines, each equipped with two RFID ceiling antennas from Feig Electronic. Once the ID of the component has been captured by the antennas, assembly begins.

In some cases, the windows must be temporarily stored in a holding or quarantine warehouse before being transported to the final assembly and inspection location. Ceiling-mounted antennas enable the localization of all windows in the warehouse in real time. Information about the location of each component and the duration of storage is stored in the ERP system.

"All production and logistics processes, all readers and antennas, and all generated data are connected to Toro Aluminum's ERP system in real time via RFID To Go and RFID Hub. These two software solutions take care of the system status of all hardware and infrastructure, as well as the integration, connectivity, and transfer of data to the application database."

Khaled Elshimy

CEO

Geolocalization on the Construction Site with LoRaWAN

The French construction company Bouygues Construction Group uses geolocation to track equipment, building materials, load carriers, and personnel. By the end of 2021, 10,000 sensors are to be integrated. In the meantime, 20,000 devices are equipped with LoRaWAN sensors for remote management and location in real time. The connection of 50,000 smaller devices is planned. The trackers have embedded sensors with a combination of different location technologies. These include GPS, low-power GPS, Wi-Fi sniffer, Bluetooth LE, and LoRaWAN TDoA geolocation technologies.

These trackers enable close-range detection. The geo-fencing function divides the device into specific zones, and position updates can be retrieved at the beginning and end of each movement. The location of each device is visualized in real time on the IoT platform. Geolocation data and activities are captured in real time. This enables the construction process to be monitored in real time.

The French construction company Bouygues Construction Group uses geolocation to track equipment, building materials, load carriers, and personnel. By the end of 2021, 10,000 sensors are to be integrated. In the meantime, 20,000 devices are equipped with LoRaWAN sensors for remote management and location in real time. The connection of 50,000 smaller devices is planned. The trackers have embedded sensors with a combination of different location technologies. These include GPS, low-power GPS, Wi-Fi sniffer, Bluetooth LE, and LoRaWAN TDoA geolocation technologies.

These trackers enable close-range detection. The geo-fencing function divides the device into specific zones, and position updates can be retrieved at the beginning and end of each movement. The location of each device is visualized in real time on the IoT platform. Geolocation data and activities are captured in real time. This enables the construction process to be monitored in real time.

"The location of each device is visualized in real time. The real-time capture of geolocation and activity data from machines enables us to monitor construction processes in real time."

Nicolas Lemaire

CEO

Real-Time Remote Worker Support with Data Glasses

Roofing company Sebastian Lohrer uses data goggles for remote support on construction sites. Drones are used to photograph roofs from the air. The detailed image data is transferred to an iPad. The company has been using the remote maintenance solution since 2022. It allows employees to communicate and work hands-free.

The solution involves the RealWear HMT-1 data glasses from COT. The data glasses are dustproof, waterproof, shockproof, and can be used at temperatures between -20 and 50 °C. The data glasses are voice-controlled and use software called Teamviewer. When employees wear the data glasses, they receive real-time support via live video transmission from any location. This is made possible by Wi-Fi connectivity. All vehicles are equipped with Wi-Fi hotspots to ensure a stable Internet connection. Employees activate the hotspot on their company mobile phone. The glasses are then connected and the application is started by voice command. The video connection is established immediately and automatically. A live feed is transmitted from the glasses to the manager's tablet. The manager can set visual markers and upload them to the glasses to provide the employee with clear guidance.

In addition to maintenance and installation on the construction site, the remote maintenance solution can also be used for quality assurance. Any discrepancies can be documented immediately in real time by remote support in the form of photos or videos. Seamless documentation is particularly important for warranty claims. Problems can be analyzed and rectified more effectively, quickly, and accurately.

"The field of vision of the glasses is transmitted to a tablet in real time. The video call can be recorded and saved for documentation purposes."

More Articles on the Construction Industry

How is Digitalization Progressing in the Industry?

Digitalization in the construction industry is, in fact, progressing rather slowly compared to logistics or industry. There are many reasons for this. On the one hand, deviations from the schedule and the delivery of construction materials are a particular reason for the integration of digital control elements, while on the other hand, the complexity of the processes does not make the integration of wireless IoT hardware and identification technologies easy. These technologies often have to be used both indoors and outdoors. They need to enable long ranges, be able to be used by different developers, which means interoperability, and work in environments where transmission networks are limited. Low Power (LP) solutions are particularly suitable in remote regions. For suppliers of building materials, where the exact time and correct delivery of the goods is absolutely essential, identification solutions for the labeling of components are ideal. UWB technology supports construction companies in localizing their assets.

Overall, the construction industry is a challenging field for wireless IT integration. This is due to complex supply chains, deviations in project planning, the need to network many different construction companies, and the cost explosion in the construction industry. Despite this challenge, the pressure to digitalize is also increasing in the construction industry, and the use of wireless IoT technologies is steadily growing.

The Future Potential of the Digital Construction Industry

The greatest future potential of digital construction lies in increasing efficiency. Automated processes and workflows increase the speed and efficiency of the entire construction project and the entire value chain. This starts with construction planning and material procurement, through to the use of equipment on the construction site, and the monitoring of construction processes. Increased efficiency also means cost savings. The intelligent use of resources, including building materials and equipment, as well as the deployment of personnel, leads to the intelligent planning of time and materials. Costs are also saved because construction machinery can be comprehensively monitored through the use of sensor technology, and predictive maintenance reduces the risk of breakdowns.

Digital technologies secure the entire construction process, i.e. the equipment and systems on the construction site, as well as the employees. If all the different parties involved in construction are interoperably networked with each other on a digital level, the added value of digital processes is not just for one company, but for all companies involved in construction. By using digital collaboration tools and a communication platform, project teams can work together more efficiently and access the same data via a team platform.

Challenges in Digital Construction Now and in the Future?

There are many challenges when it comes to digitalization in the construction industry. These include the complex process steps involved in constructing a building, a tunnel, or a power plant. A large number of trades, building materials, and suppliers have to work together. Even if numerous assets such as construction machinery, tools, or building materials are identified via transponders or sensors, the various construction companies must be able to access this data interoperably in order to derive the greatest possible benefit from the technology. This is no trivial task, as it often involves sensitive information. For data protection reasons, this information cannot be made generally accessible.

The increasing networking of construction processes also increases the risk of cyberattacks. Protecting the digital infrastructure is therefore of great importance. Another hurdle in the digitalization of the construction industry is the investment costs in hardware and software as well as employee training and the cost-benefit ratio. The shortage of skilled workers also poses a challenge for digitalization in the construction industry. These reasons mean that although the construction industry is steadily moving towards digital transformation, this development is not progressing quickly.

Partners Spezialized in Construction Solutions

Innovative Trends on the Path Towards the Digital Construction Site

Robots

Robots and automated construction equipment are increasingly being used to carry out repetitive tasks on construction sites. This increases productivity and transforms work processes. Automated processes reduce the workload in times where there is a shortage of skilled workers.

Artificial Intelligence

The integration of identification technologies and IT platforms not only generates big data, but also enables companies to evaluate and interpret the available sensor data in the form of statuses or locations, and draw conclusions about expected developments. Analysis tools help to identify patterns and algorithms, and activate maintenance intervals with foresight, for example. Artificial intelligence can be used to assess the risk of material bottlenecks.

Digital Twin

By creating digital twins of buildings and infrastructure, planners and operators can optimize performance over the entire life cycle by using data from real operations to make predictions and improvements.

Virtual Reality (VR) and Augmented Reality (AR)

VR and AR are increasingly being used in the construction industry with the aim of virtually inspecting construction sites. This saves time and costs, and reduces the carbon footprint, while allowing changes to be made in real time. Virtual construction site visits also make it possible to visualize construction models in 3D, and provide training programs for construction workers.