UHF RFID

Pierre Muller is the RFID Business Unit Manager at EM Microelectronic, responsible for overseeing all RFID-related activities within the company. His career began as a digital design engineer in mixed-signal environments, progressing to roles in technical leadership, project management, and team management. With 12 years of experience in the wireless industry, he has worked with key connectivity standards, including Bluetooth, Wi-Fi, GSM, 3G, and LTE.

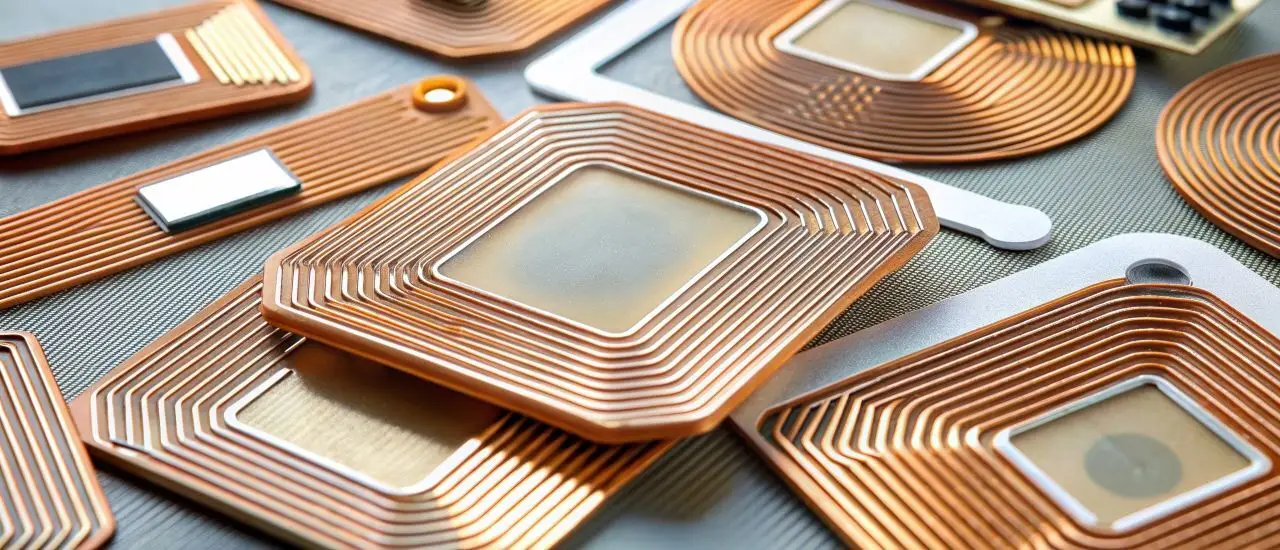

Over the years, RFID systems have evolved from their infancy to sophisticated solutions. Today's RFID chips offer improved performance, greater functionality and have become more cost-effective.

According to the RAIN Alliance's Global Markets & Applications for RAIN Solutions report of June 2024, UHF RFID chip shipments are expected to reach 115 billion units by 2028. The compound annual growth rate of UHF RFID chip shipments is 20.4 percent. Another Gartner report predicts that next-generation RFID will be a fundamental part of 20 percent of all supply chain technology solutions.

Recent developments for the UHF RFID sector include the release of the Gen2v3 air interface protocol for UHF RFID technology in 2024 and the recent introduction of Gen2X by Impinj in January 2025. UHF RFID is also expected to be a key technology supporting the Digital Product Passport initiative. Mandatory implementation of the Digital Product Passport (DPP) in the EU is expected by 2027/2028.

These advances have driven and continue to drive widespread adoption, with applications extending beyond retail into industries such as tyre manufacturing and industrial logistics, where adoption has surged in recent years. In fact, more than two billion RFID tags will be sold in the tyre industry in 2024 alone.

Another challenge in industrial projects is the complexity of the environment. From the variety of machinery to the presence of metals, liquids and stringent requirements for tracking equipment and consumables, there are many variables to consider. Some challenges are mitigated at the tag and inlay level, such as the development of on-metal tags. Others, however, require advanced or customised integrated circuits (ICs) to meet the diverse requirements.

Over the years, RFID systems have evolved from their infancy to sophisticated solutions. Today's RFID chips offer improved performance, greater functionality and have become more cost-effective.

According to the RAIN Alliance's Global Markets & Applications for RAIN Solutions report of June 2024, UHF RFID chip shipments are expected to reach 115 billion units by 2028. The compound annual growth rate of UHF RFID chip shipments is 20.4 percent. Another Gartner report predicts that next-generation RFID will be a fundamental part of 20 percent of all supply chain technology solutions.

Recent developments for the UHF RFID sector include the release of the Gen2v3 air interface protocol for UHF RFID technology in 2024 and the recent introduction of Gen2X by Impinj in January 2025. UHF RFID is also expected to be a key technology supporting the Digital Product Passport initiative. Mandatory implementation of the Digital Product Passport (DPP) in the EU is expected by 2027/2028.

These advances have driven and continue to drive widespread adoption, with applications extending beyond retail into industries such as tyre manufacturing and industrial logistics, where adoption has surged in recent years. In fact, more than two billion RFID tags will be sold in the tyre industry in 2024 alone.

Another challenge in industrial projects is the complexity of the environment. From the variety of machinery to the presence of metals, liquids and stringent requirements for tracking equipment and consumables, there are many variables to consider. Some challenges are mitigated at the tag and inlay level, such as the development of on-metal tags. Others, however, require advanced or customised integrated circuits (ICs) to meet the diverse requirements.

Pierre Muller is the RFID Business Unit Manager at EM Microelectronic, responsible for overseeing all RFID-related activities within the company. His career began as a digital design engineer in mixed-signal environments, progressing to roles in technical leadership, project management, and team management. With 12 years of experience in the wireless industry, he has worked with key connectivity standards, including Bluetooth, Wi-Fi, GSM, 3G, and LTE.

Custom ICs for Specialized Applications

Tailoring an RFID IC to specific customer requirements or needs enables innovative and highly specialized solutions. Semiconductor manufacturer EM Microelectronic, for example, has developed the world's smallest and thinnest RFID tags, measuring 1.6mm x 1.6mm with a thickness of 150µm.

This was achieved by integrating an IC core on silicon wafers in combination with a coil-on-chip antenna. The result is a complete tag solution on wafer with a near field communication range of approximately one centimeter. Such a compact form factor is highly advantageous for applications that require minimal space while still providing reliable near-field performance.

A booster antenna can be integrated to extend the tag's range up to four meters, enhancing its functionality for use cases such as PCB track-and-trace in industrial, automotive and aerospace applications. This is an example of an application where an extremely compact form factor is essential. In this scenario, the booster antenna can be printed directly on the PCB, with the RFID IC mounted on the same board. This design maximizes range and enables identification and tracking capabilities while maintaining an extremely compact profile.

Such configurations demonstrate how custom RFID IC solutions can be applied to highly specialized use cases in various industries.

UHF RFID and NFC operate in different frequency bands. UHF uses the 860-960 MHz band, while NFC uses the 13.56 MHz band. By combining the two technologies, a combination of diverse applications are made possible.

Dual Frequency

Because industrial projects have large infrastructure investments and long life spans, this often results in a mixed supply chain management infrastructure where UHF RFID operating in the 860 to 960 MHz band is used for certain processes, while HF RFID tags address specific needs in others.

In this context, different technologies are critical to meet the unique needs of different industries. Dual frequency technology has emerged as a transformative solution, bridging the gap between different systems and enabling companies to optimize operations in diverse environments.

EM Microelectronic was the first to bring dual-frequency chips to market with the RAINFC chip combination. The em|echo was introduced in 2016 and was replaced in 2020 by the second chip generation: the em|echo-V.

Whether a legacy infrastructure is built on HF technology or on UHF RFID, dual-frequency solutions can ensure seamless integration. You can implement UHF RFID where it aligns with business objectives, while leveraging HF or NFC technology to enable enhanced product interaction.

However, applying these technologies across different use cases is not without its hurdles. Technologies designed for specific applications, such as retail, often fail to meet the unique and demanding requirements of industrial use cases.

With longer decision cycles, lower production volumes and highly specific requirements, industrial sectors often face challenges when attempting to adapt off-the-shelf RFID solutions. This underscores the importance of tailored approaches to ensure the effective implementation of technologies in industrial applications.

The next section of this article will focus on specific use cases for UHF RFID and dual frequency technologies.

RFID and NFC Technology in Use at SBB

The rail industry presents unique challenges for RFID deployments, particularly in scenarios involving long lifecycles and changes in ownership of assets such as train wagons. Unlike consumer products, rail vehicles require reconfigurable Electronic Product Codes (EPCs) to adapt to new ownership or operational requirements in different countries. This challenge has been addressed in a collaboration between semiconductor manufacturer EM Microelectronic and the Swiss Federal Railways (SBB).

SBB has been using UHF RFID for more than a decade. The railway company is gradually building an efficient system around the technology for continuous condition monitoring and maintenance planning of its rail vehicles.

UHF RFID is used for high-speed (250 km/h), long-range vehicle identification, while NFC technology is now being used for maintenance operations.

Typical use cases for UHF RFID in rail maintenance, repair, and operations (MRO) include wheel load and hot box detection, acoustic measurement systems for axle and traction motor bearings, wayside wheelset measurement systems, and confirmation and billing of automated vehicle exterior cleaning.

On the other hand, SBB uses NFC technology for underfloor lathes and similar production machines, portable wheelset measuring systems in the workshop, confirmation of technical checks and interior cleaning in marshalling yards, registration of corrective work orders in operations and maintenance.

A critical requirement is to ensure accurate identification of individual components, such as bogies or wheels, which are often swapped between vehicles during maintenance operations.

Maintenance records need to be associated with these components, rather than the train itself, to support effective lifecycle management. A combination of UHF RFID and NFC technology is used for vehicle and component identification in maintenance and in the supply chain. The result: real-time diagnostics of rolling stock and 100% vehicle identification.

Train maintenance must be properly managed and executed. Trains cannot be left for long periods of time in the workshop for maintenance. RFID and NFC technologies can be used to monitor the condition of train components to ensure that parts that require maintenance are detected early on, so that maintenance can be carried out before the damage escalates.

Digital Twin for Predictive Maintenance

In practice, SBB maintains a digital twin of each train in its ERP system, which is key to predictive maintenance. SBB is currently using UHF RFID and QR code technology. QR codes are currently used to identify components during maintenance. However, QR codes often become soiled and difficult to read. This led SBB to investigate NFC as an alternative solution.

One of the key benefits of this use case is data consistency with the shared memory architecture and seamless access via both UHF RFID and NFC interfaces. This eliminates the need for duplicate programming during maintenance operations.

SBB was also on the search for a solution that could better identify the tag through the NFC interface. They also wanted to enable shared passwords between both interfaces in order to simplify the infrastructure and access rights management. As result, we customized our latest generation of dual-frequency em|echo-V chips to meet SBB’s specific operational needs. Our latest product, the em|echo-I has already been successfully tested, and we are eager to see this product on the Swiss railroad starting from Q1 in 2025.

EM Microelectronic's new em|echo-I chip integrates a larger tag memory, which is often required when seamless network connectivity is not available in the application. With larger memory comes the challenge of accessing data efficiently. As a solution, the recent Gen2v3 standard on the UHF side provides new capabilities such as dynamic power adjustment for improved tag identification and system efficiency.

It is also fully backward compatible with existing readers. With the introduction of the em|echo-I as a full Gen2v3 product, EM Microelectronic is driving the adoption of the new standard and has provided SBB with future-proof solutions for long-term reliability and performance.

Combining UHF RFID and HF RFID in Healthcare

Similar to the industrial sector, healthcare presents unique challenges for inventory management and process automation due to the complexity of its supply chain and critical operating environments. Dual-frequency technology can be used to address these challenges.

For example, WaveMark, a division of Cardinal Health, has deployed both UHF and HF RFID solutions across the healthcare supply chain, from large-scale inventory tracking to point-of-use applications.

UHF RFID is primarily used for supply chain and inventory management, providing long-range and high-volume reading capabilities. Meanwhile, HF RFID is used in smart cabinets and operating rooms. In the surgical environment, HF RFID enables automated documentation of equipment usage, verification of expiration dates, and identification of recalled items. This not only minimizes medical errors, but also potentially saves lives. The data collected is simultaneously logged into patient records, ensuring accurate documentation and reducing administrative burden.

Combining RFID with Sensor Technology

em|aura-sense

- EPC and UHF RFID IC from EM Microelectronic

- A chip combining capacitive sensing with UHF RFID technology

- Applications: Smart manufacturing, industry 4.0, predictive maintenance, IoT applications, industrial sensing, home automation

- Compliant with ISO/IEC 18000-63 and EPC Gen2v2

The integration of sensing capabilities into RFID technology has transformed the potential applications of completely passive RFID systems. Consider scenarios such as detecting moisture in automotive manufacturing, managing environmental conditions in large greenhouses, or monitoring industrial machinery for overheating. All of these use cases can be addressed using standard passive RFID technology combined with sensors.

By combining both UHF RFID infrastructure and advanced sensing capabilities, companies can perform capacitive sensing. This opens up a wide range of applications, including moisture detection, light intensity monitoring and proximity sensing. EM Microelectronic's em|aura-sense is an example of how a conventional passive RFID chip has been upgraded to a fully functional sensing device.

The integration of sensing capabilities into RFID technology has transformed the potential applications of completely passive RFID systems. Consider scenarios such as detecting moisture in automotive manufacturing, managing environmental conditions in large greenhouses, or monitoring industrial machinery for overheating. All of these use cases can be addressed using standard passive RFID technology combined with sensors.

By combining both UHF RFID infrastructure and advanced sensing capabilities, companies can perform capacitive sensing. This opens up a wide range of applications, including moisture detection, light intensity monitoring and proximity sensing. EM Microelectronic's em|aura-sense is an example of how a conventional passive RFID chip has been upgraded to a fully functional sensing device.

em|aura-sense

- EPC and UHF RFID IC from EM Microelectronic

- A chip combining capacitive sensing with UHF RFID technology

- Applications: Smart manufacturing, industry 4.0, predictive maintenance, IoT applications, industrial sensing, home automation

- Compliant with ISO/IEC 18000-63 and EPC Gen2v2

We work at the standard level to ensure that all data is accessible through standardized interfaces and are not bundle-specific. This is why we have integrated the Snapshot Sensor concept into the Gen2v2 standard. Additionally, by fully decoupling the sensing and RF elements, the chip ensures high-quality, reliable data that can be seamlessly integrated into existing systems.

Capacitive Sensing in Automotive Applications

RFID and sensor technologies are widely used in automotive manufacturing, particularly for monitoring critical environmental and operational parameters. Capacitive sensing, a key application in this sector, can be used to detect potential water leaks during the production process. It also facilitates real-time monitoring of machine or engine performance by detecting overheating events.

A real-world example is the multi-temperature digital indicator developed by Thai electronics company Cleantech and Beyond, which integrates the em|aura-sense chip. This technology is used to detect overheating in engines. Capacitive sensors embedded with advanced RFID chips can accurately measure temperature changes.

This is achieved by incorporating materials that exhibit capacitance changes in response to environmental parameters such as temperature fluctuations. This allows the tag to detect temperature changes through capacitive sensing. The tag is also available in an NFC or QR code variant.

A key advantage of this system is the irreversibility of material changes when exposed to extreme temperatures. This ensures that any temperature excursion is recorded, even if the RFID tag is not actively powered. This battery-free design allows for continuous monitoring. In addition, the system provides both visual feedback-through a color change in the material for personnel inspections-and digital data that can be efficiently read during routine inventory scans. The captured sensor data can then be integrated into enterprise resource planning (ERP) systems.

Smart irrigation with RFID and sensor technology is not only limited to smart greenhouses. Farmers can use this method on their crops in fields as well.

Soil Moisture Monitoring with Capacitive Sensors

Another application for capacitive sensing with RFID is environmental monitoring in agriculture. This is where greenhouses get smart.

In practice, capacitive sensing technology is ideal for detecting soil moisture levels, which enables precise irrigation management. Semiconductor manufacturer EM Microelectronic, for example, has teamed up with Microsensys to develop an innovative tag for soil moisture sensing. The em|aura-sense tag is planted with each plant. The tag enables continuous monitoring of soil moisture levels in real time.

This capability allows automated irrigation systems to optimize water delivery to each individual plant based on its specific needs, reducing resource waste while ensuring optimal growing conditions.

Studies have also shown that UHF RFID tags with capacitive sensors have been used to monitor landslides. The sensor tag is planted near the surface of the soil. By monitoring the water content of the soil in at-risk areas, the likelihood of a landslide can be predicted and appropriate evacuation or safety measures can be taken in advance to prevent disaster.

Pick-by-Light Applications

RFID technology, when integrated with sensor-based solutions, can also be used to address complex operational challenges, such as pick-by-light applications in data centers and similar environments. Identifying specific components, such as a faulty cable flagged by an IT system, can often be challenging, especially in dense or disorganized environments. To simplify this task, RFID technology can be adapted to integrate visual indicators directly into the system.

Standard RFID ICs can be reconfigured to integrate application-specific requirements. For example, LEDs can be associated with specific cables or components.

Once the unique identifier (UID) of the desired item is provided, the system activates the corresponding LED, visually pinpointing its location. This approach greatly simplifies the retrieval process and reduces the time required for maintenance or troubleshooting.

Security is Key in Every Industry

Trust is the foundation of any business, and secure solutions are essential to building trust. Security is critical in every industry, and RFID technology plays a critical role in protecting applications from counterfeiting and unauthorized access.

From retail and pharmaceuticals to automotive and industrial, counterfeit and unauthorized parts can have serious consequences, compromising both quality and safety. To address these challenges, RFID IC solutions are often customized to integrate advanced security features and communication protocols tailored to specific customer requirements.

Embedding cryptographic functions in UHF RFID tags is a complex process that requires a combination of expertise in both security and low-power operation. These tags often incorporate algorithms such as the AES Crypto Core and other specialized protocols, such as the one time password algorithm, designed for unique applications such as Web authentication and secure access control.

Security should not be taken lightly as mistakes are easily made and costly. At EM Microelectronic, we customize our IC solutions to embed specific protocols, such as Artefato, P63, and Siniav in Brazil. Our aura-C crypto-enhanced UHF RFID ICs are ISO29167-compliant and have up to six crypto keys. We also deliver the security solutions for HF products, as we did with the EM4237 NFC/HF IC. This makes the IC suitable for closed-loop and access control applications. Brand protection is one of our key focuses.

-über-Wi-Fi-HaLow-responsive.webp)