Rinas Gerätetechnik

We are Rinas Gerätetechnik

Armin Rinas

Managing Director

"High-precision "Made in Germany" hardware components are combined with a proprietary modular software suite that allows machine control according to exact customer requirements."

We Don‘t Just Make Devices. We Set Standards!

Making top-quality devices and machines is one thing. Developing technologies is another, and that is exactly what has always driven us: the continuous search for new and optimum solutions to suit the requirements of our customers. It comes as no surprise then, that our team in D-88634 Aftholderberg, Germany is always coming up with innovations that set standards.

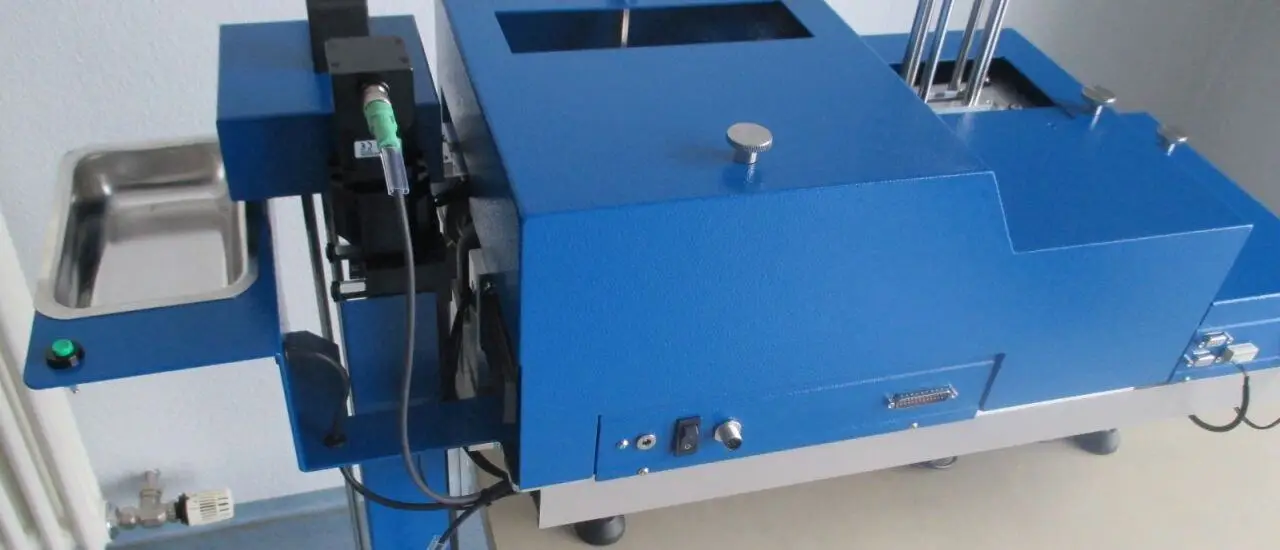

Whether wishing to integrate a drop-in (OEM) encoding system in an already existing manufacturing line or deciding to purchase a stand-alone solution, capable of handling all aspects of the personalization process, Rinas can assist with the all-important yet often challenging decision-making task.

The Rinas legacy has always been at the heart of the personalization environment – where the encoding takes place – and, because of its success and hard-earned reputation in this field, Rinas has moved forward, breaking away from being ‘ just’ a component supplier, and developed its own range of peripheral equipment to complement its encoder family and create a personal environment that is not only environmentally friendly but also extremely compact.

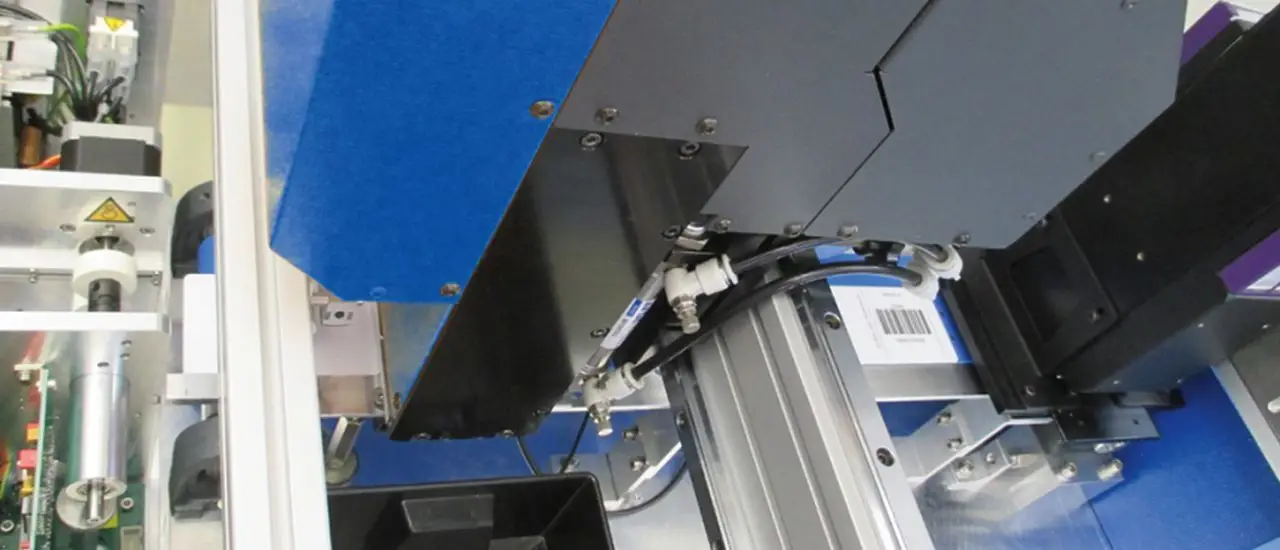

Even the multitude of bespoke solutions working hard around the globe preparing public transport tickets, processing bank books, creating loyalty cards or verifying security certificates all feature the same common, reoccurring elements: thoroughness of design, precision engineering and longevity.

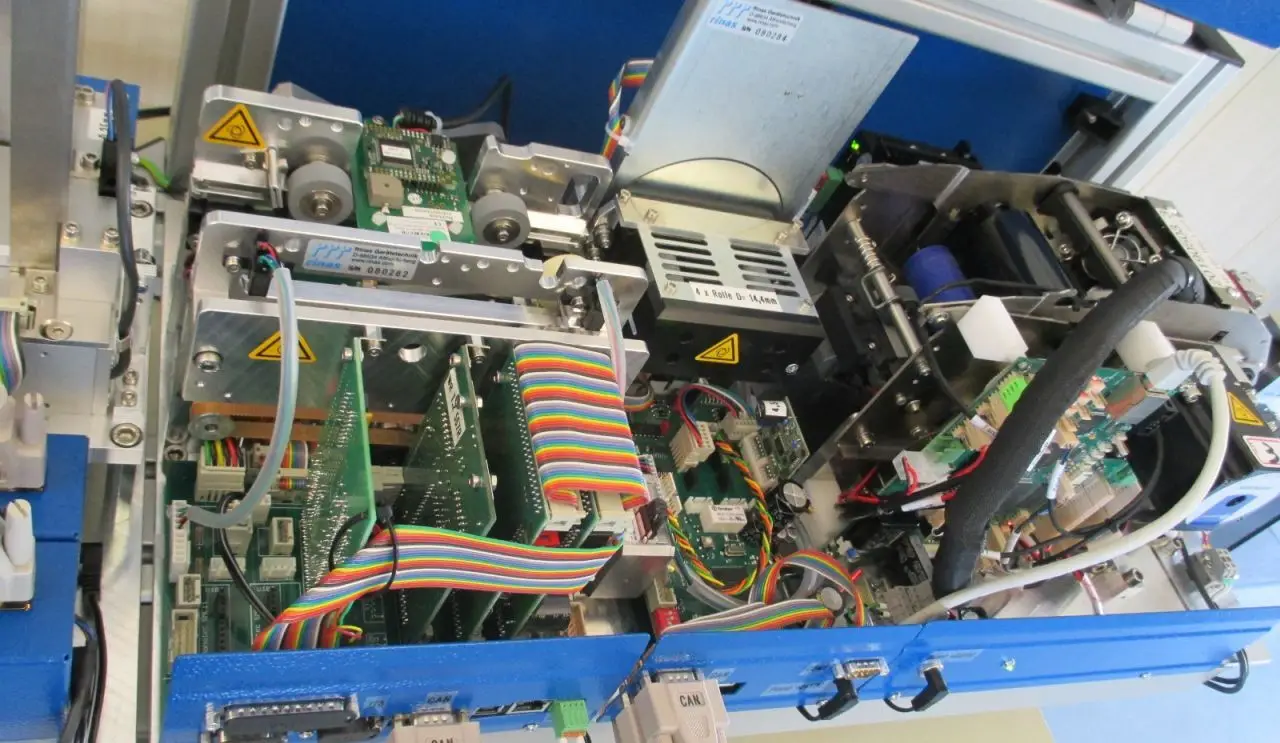

- Production equipment for RFID, magnet and Smart Cards

- Individual or continuous ticket encoding

- Card handling (separating, printing, scanning, sorting, stacking)

- Bespoke machinery / customer-specific engineering

- Electronic component and software development

Success Stories with Rinas

News from Rinas

Products of Rinas

We’re Here For You!

Armin Rinas

Managing Director

-über-Wi-Fi-HaLow-400.webp)