CS-DOD System by Rinas in Use at PAV Card

Use Cases for Card Personalization

Thomas Keller heads card personalization at PAV Card, bringing over 25 years of experience. He oversees order processing, ensures smooth operations, and steps in at the machines when needed.

The Rinas machine is used to personalize a wide range of card types, including gift cards, membership IDs, and health insurance cards. Designed for high-volume production, it is deployed by businesses, banks, insurance companies, and municipal institutions.

Large-scale orders involving several million cards are a key part of the production process. At the same time, smaller orders are also handled efficiently — often consisting of just 200 to 300 cards. These typically come from sports clubs or smaller organizations and are processed on a weekly or monthly basis. The system is configured even for low volumes, ensuring both one-time and recurring jobs can be carried out with maximum efficiency.

For a private health insurance provider, the machine produces membership cards with printed names, membership numbers, and additional data. While these cards currently do not include RFID functionality, a transition to RFID is technically feasible.

Cities and municipalities also rely on this technology — for example, the City of Hamburg uses it for administrative purposes, while the City of Lübeck employs it for fire and police department cards. In the retail sector, gift cards are produced for customer loyalty programs and promotional campaigns.

The Rinas machine is used to personalize a wide range of card types, including gift cards, membership IDs, and health insurance cards. Designed for high-volume production, it is deployed by businesses, banks, insurance companies, and municipal institutions.

Large-scale orders involving several million cards are a key part of the production process. At the same time, smaller orders are also handled efficiently — often consisting of just 200 to 300 cards. These typically come from sports clubs or smaller organizations and are processed on a weekly or monthly basis. The system is configured even for low volumes, ensuring both one-time and recurring jobs can be carried out with maximum efficiency.

For a private health insurance provider, the machine produces membership cards with printed names, membership numbers, and additional data. While these cards currently do not include RFID functionality, a transition to RFID is technically feasible.

Cities and municipalities also rely on this technology — for example, the City of Hamburg uses it for administrative purposes, while the City of Lübeck employs it for fire and police department cards. In the retail sector, gift cards are produced for customer loyalty programs and promotional campaigns.

Thomas Keller heads card personalization at PAV Card, bringing over 25 years of experience. He oversees order processing, ensures smooth operations, and steps in at the machines when needed.

Versatile Personalization Process

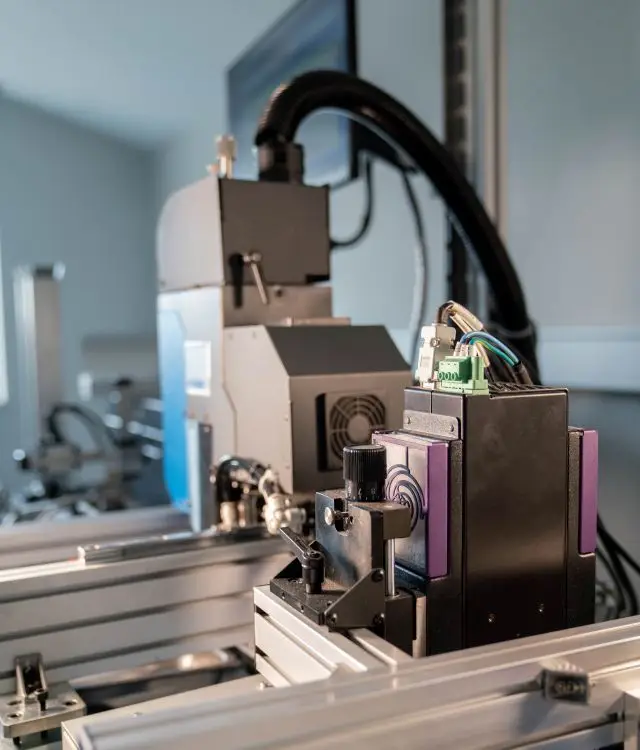

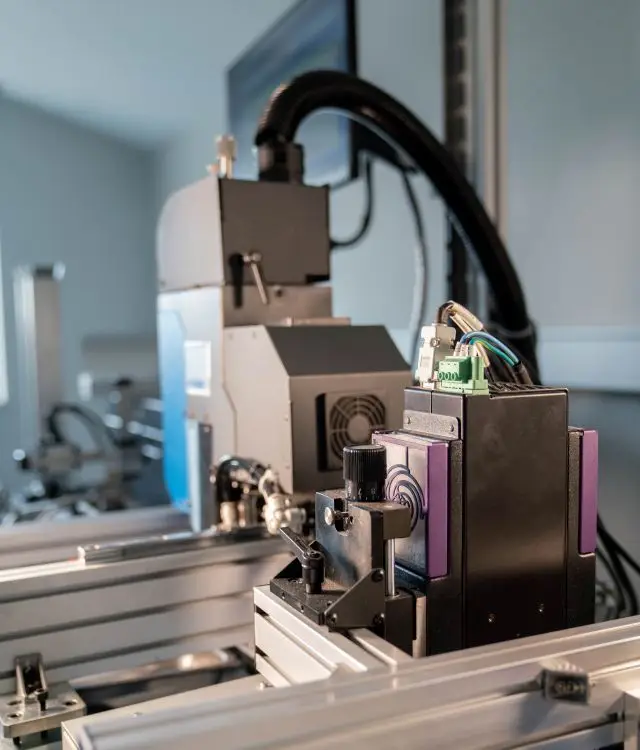

The RINAS CS-Laser system provides a scalable and versatile solution for encoding and labeling cards made from materials like polymers, wood, and metal. (Image: Rinas Gerätetechnik)

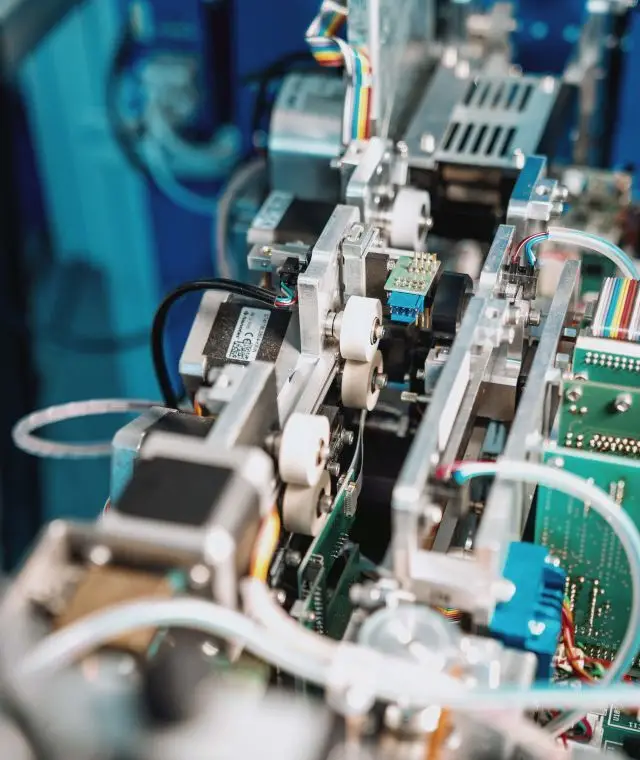

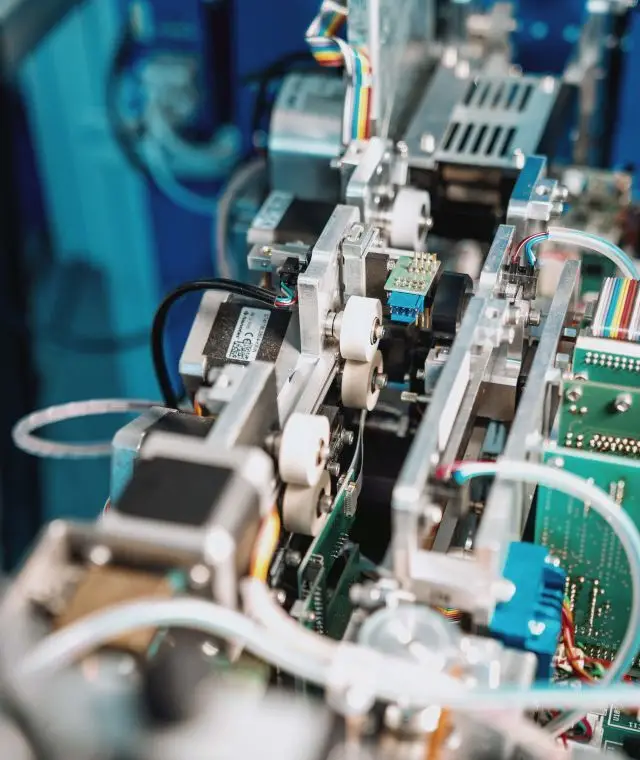

The personalization of RFID cards on the 6-meter-long Rinas machine begins with the feeding of blank cards. As soon as a card enters the system, it passes through two RFID stations equipped with contactless readers. At these stations, the card’s UID is read and logged. This data is used, for example, for verification or to search corresponding records in a database. Immediately afterward, magnetic stripe encoding takes place, writing relevant data to the magnetic stripe.

Following encoding, the card undergoes plasma treatment, which optimally prepares the surface for the subsequent inkjet drop-on-demand (DOD) printing. Plasma treatment alters the surface structure of the card so that the ink adheres better and the print appears sharper. The card is then printed using a black-only inkjet printer. A UV dryer ensures that the ink cures quickly, allowing the card to proceed directly to the next production step.

At the end of the process, a labeling unit applies a scratch-off label to conceal a previously printed PIN code, which has been verified against a database. A camera system then checks the correct placement of the label.

The personalization of RFID cards on the 6-meter-long Rinas machine begins with the feeding of blank cards. As soon as a card enters the system, it passes through two RFID stations equipped with contactless readers. At these stations, the card’s UID is read and logged. This data is used, for example, for verification or to search corresponding records in a database. Immediately afterward, magnetic stripe encoding takes place, writing relevant data to the magnetic stripe.

Following encoding, the card undergoes plasma treatment, which optimally prepares the surface for the subsequent inkjet drop-on-demand (DOD) printing. Plasma treatment alters the surface structure of the card so that the ink adheres better and the print appears sharper. The card is then printed using a black-only inkjet printer. A UV dryer ensures that the ink cures quickly, allowing the card to proceed directly to the next production step.

At the end of the process, a labeling unit applies a scratch-off label to conceal a previously printed PIN code, which has been verified against a database. A camera system then checks the correct placement of the label.

The RINAS CS-Laser system provides a scalable and versatile solution for encoding and labeling cards made from materials like polymers, wood, and metal. (Image: Rinas Gerätetechnik)

Modular Design for Customized Configuration

The Rinas encoding system features a modular design, allowing individual components—such as the plasma treatment module—to be added or removed as needed. This flexibility makes the machine highly adaptable and future-proof for a wide range of personalization requirements.

Quality Assurance Through Advanced Inspection Technology

The personalization machine from Rinas Gerätetechnik relies on advanced camera technology to monitor the production process in real time. Multiple cameras are installed at various points in the system, capturing the cards from both above and below. They verify that each step is carried out correctly, detect errors, and allow for rapid data matching.

If a card requires double-sided printing, a QR code is applied during the first pass. During the second pass, the machine reads this code to ensure accurate personalization on the reverse side. The cameras ensure that all process steps are performed correctly, providing a high level of production security.

The personalization machine from Rinas Gerätetechnik relies on advanced camera technology to monitor the production process in real time. Multiple cameras are installed at various points in the system, capturing the cards from both above and below. They verify that each step is carried out correctly, detect errors, and allow for rapid data matching.

If a card requires double-sided printing, a QR code is applied during the first pass. During the second pass, the machine reads this code to ensure accurate personalization on the reverse side. The cameras ensure that all process steps are performed correctly, providing a high level of production security.

Security in Card Personalization

Card personalization and processing are carried out under strict security measures to ensure data integrity and prevent unauthorized access. The entire process begins with the encrypted transmission of data provided by the customer. These personalized details—such as names or identification numbers—are prepared by PAV Card’s internal IT department and then transferred to production.

As the cards being processed do not contain a chip—neither contactless nor contact-based—no RFID personalization takes place. Instead, the cards are personalized visually by printing a QR code and a confidential PIN, which is then covered with a label. This code is linked to a database and serves to identify the card.

Despite the absence of RFID chips, the security standards remain high. Before the label is applied, the confidential number is read and verified against the database to ensure accuracy. In addition, check digits printed on the card help prevent tampering, further enhancing the security and reliability of the personalized cards.

Interview with Thomas Keller

1. What advantages does the Rinas machine offer compared to other systems in your equipment fleet?

Thomas Keller: A key advantage of the Rinas CS-DOD card personalization system is its user-friendly operation. Setting up new jobs is quick and straightforward, which increases overall efficiency. With an impressive processing speed of up to 6,000 cards per hour, the machine offers significant benefits—especially for the personalization of gift cards and similar products.

Another major strength is its reliability. The machine operates consistently and requires only minimal maintenance. While regular servicing is necessary, major breakdowns or unexpected downtimes are rare. This helps keep overall operating costs low and ensures a consistently high production quality.

Thomas Keller: A key advantage of the Rinas CS-DOD card personalization system is its user-friendly operation. Setting up new jobs is quick and straightforward, which increases overall efficiency. With an impressive processing speed of up to 6,000 cards per hour, the machine offers significant benefits—especially for the personalization of gift cards and similar products.

Another major strength is its reliability. The machine operates consistently and requires only minimal maintenance. While regular servicing is necessary, major breakdowns or unexpected downtimes are rare. This helps keep overall operating costs low and ensures a consistently high production quality.

2. Can the Rinas machine also personalize RFID cards, and are there any plans to use this function in the future?

Thomas Keller: In principle, yes! Currently, however, the machine is only used to read RFID cards. A custom software solution was developed for this purpose. Direct encoding is not currently integrated, as these processes are handled by other machines. Technically, an upgrade would be entirely feasible—for example, by adding an external module with a dedicated computer to handle the encoding.

At present, there is no specific demand for this functionality. However, if that changes, upgrading the Rinas machine would be a practical option that could be implemented in collaboration with Rinas Gerätetechnik.

3. You’ve been using the Rinas machine for three years. How do you rate its performance and the support provided?

Thomas Keller: We are very satisfied with the machine. It’s a system that, fortunately, has given us no technical problems. The quality and reliability truly reflect the “Made in Germany” standard. Support from Rinas Gerätetechnik is dependable, efficient, and highly competent. Whenever we do have inquiries, they are usually related to software adjustments for specific customer requirements.

For example, if an additional line of personalization is needed, the Rinas team quickly provides a solution. They develop tailored adaptations to make the machine flexible for new demands. In this sense, we didn’t just acquire a machine—we also gained reliable IT support for long-term operation.

About PAV

PAV Card is a leading full-service provider of high-quality print products, cards, mailings, masks, and software solutions. The company delivers tailored solutions for both large-scale and small-scale projects.

Its range of services includes everything from the personalization of vehicle cards for the automotive industry in large volumes to the processing of smaller orders for clubs, municipal institutions, and various organizations.

-über-Wi-Fi-HaLow-400.webp)

-über-Wi-Fi-HaLow-responsive.webp)