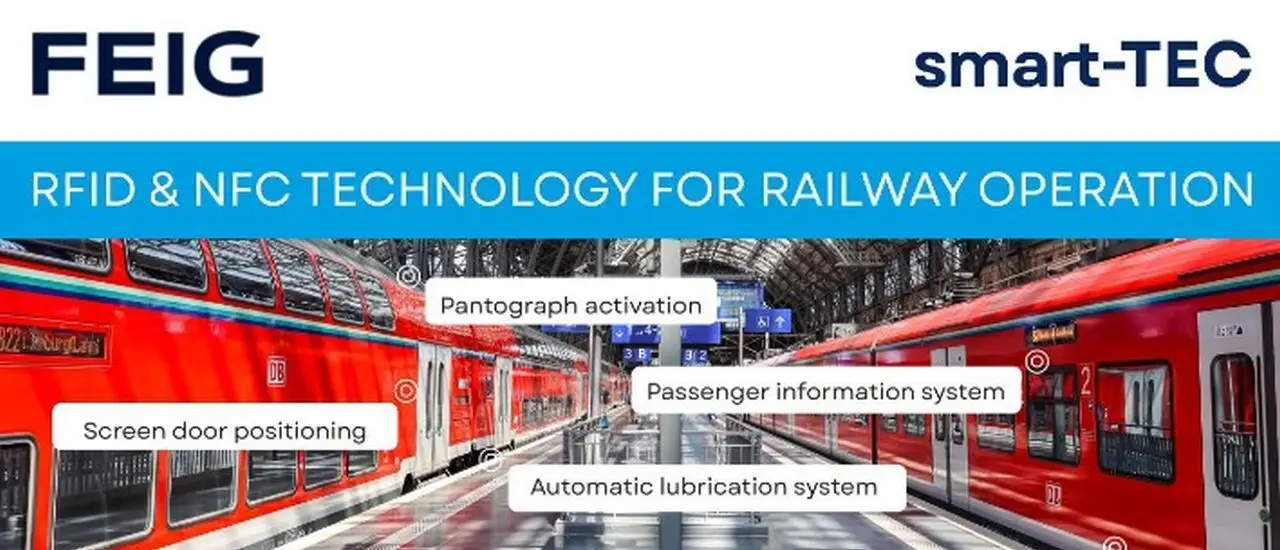

FEIG Presents Innovative Auto-ID Solutions for Railways

Revolutionizing Railway Operations with Auto-ID Technologies

Public transport is in a state of upheaval. A lot is happening on the railway lines, because digitization is continuing to be the keyword in 2024! The maintenance and repair, the day-to-day operation, the infrastructure, timetable optimization, passenger information systems and many other processes should not only become better, safer, more cost-effective and more efficient, but also be optimally coordinated with each other.The secure and complete identification and marking of rails, trains, buildings, and components are the basis for the success of the digitization project.

At this year's InnoTrans from September 24 - 27, the companies FEIG ELECTRONIC, smart-TEC and Wilmsmeier Solutions will jointly show (Hall 2.1 / Booth 245) what modern Auto-ID technology can do. RFID/NFC technology and 2D codes have been used worldwide for over 25 years in a wide variety of applications, companies, and industries.

Digitally marked components, rails, switches, machines, trains, wagons, and tools can be digitally recorded fully automatically, error-free and in a short time.

Maintenance measures and histories are automatically recorded, documented, and clearly assigned to the corresponding components. Entire train configurations are detected even during the journey and synchronized with the data from axle counting systems.

Through wayside monitoring with robust and reliable UHF RFID readers and antennas as well as RFID rail markings attached along the track or on the vehicle, trains automatically detect the platforms and stop precisely in the right place. The position of trains, trams and subways is determined extremely accurately by the vehicle itself. Systems for rail head treatment work fully automatically and activate or deactivate themselves independently on the right track sections.

Marking of Rails and Welds with AUTO-ID Technology

RFID and 2D code identification solutions with a new clamping mechanism and integrated barbs can be used to identify switches, rails, and welds in the track bed safely and easily. A simple hammer blow is enough to attach the clamping solution quickly and easily to the rail foot.

The clamps offer an exceptionally high holding force but can also be easily removed thanks to their special design.

These solutions are extremely robust and can withstand adverse environmental conditions such as extreme cold, heat, mechanical stress, and compaction of the ballast bed.

We Will Show You What Has Proven Itself in Practice for Many Years

Live applications vividly demonstrate what is possible and has proven itself in practice for many years. Of course, innovations will not be neglected: From robust RFID/NFC transponders for installation in the track bed or on the bogie, from wayside monitoring, from rail clamps, from special transponders for concrete sleepers and the wheelset brand to the robust UHF RFID reader for train assembly, everything will be shown live.

25 Years of smart-TEC

smart-TEC, the specialist for customer-specific RFID/NFC transponders and Auto-ID technology for over 25 years, will be showing solutions and designs specially developed for the railway industry. Optimally tailored to the respective requirements of the railway industry in terms of mechanical, thermal, and chemical resistance, smart-TEC offers RFID/NFC transponders for almost every application. Whether welds in the rail network, safety-relevant components in the wagon or the entire wagon need to be clearly and traceably marked... smart-TEC offers the appropriate solution.

RFID Components for Use in Rail and Bus Transport

FEIG has been developing and manufacturing RFID technology for more than 30 years, offering a wide range of UHF products. Long-range readers for use along the route and onboard solutions enable a wide range of applications to make transport systems more efficient, safer, and more reliable. RFID readers and detectors generally transmit the read/detected data to the respective higher-level control system. Loop detectors are also offered for traffic monitoring.