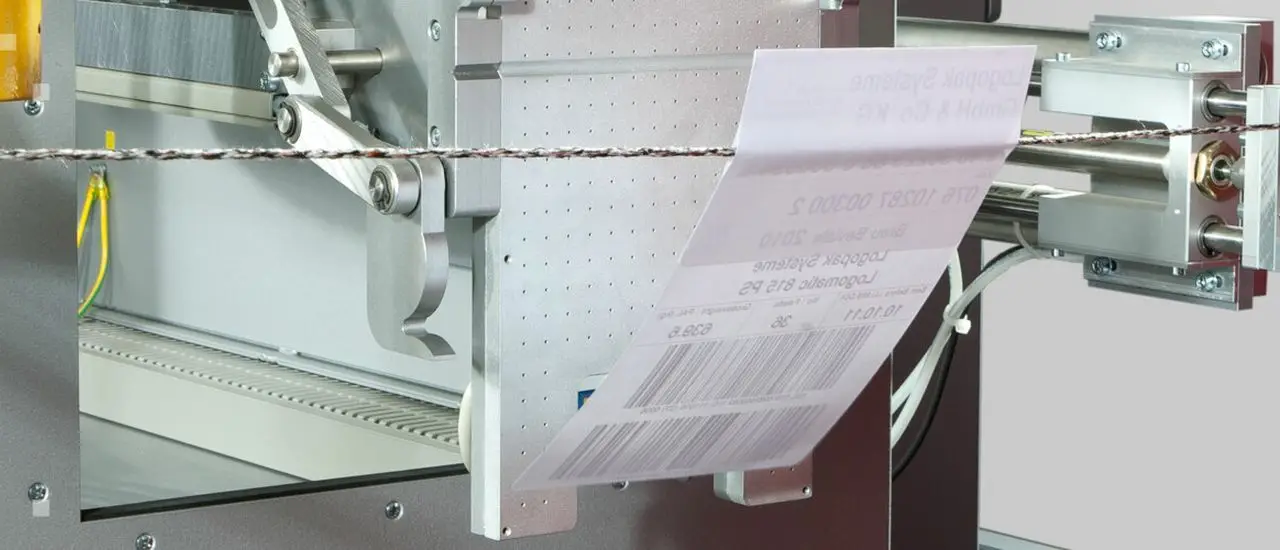

Logopak Launches the New Logomatic 850 PSC Cord Labeling System

Residue-free labeling of returnable beverage crate pallets

For the first time at BrauBeviale, Logopak Systeme is presenting its innovative Logomatic 850 PSC cord Labeling machines, designed for residue-free Labeling and identification of pallets with returnable beverage crates. The labels dispensed by the system are attached to a reusable cord made from recycled textile fibers.

In addition to improved process efficiency - the label is applied in a single step during the strapping process - the Logomatic 850 PSC makes a significant contribution to sustainability by eliminating the need for plastic strapping to secure labels. In addition, reusable crates are free of label material and adhesive residue after use.

By using FSC-certified linerless labels, the system eliminates liner waste and minimizes the carbon footprint of the labeling process.

Breweries, mineral water producers and beverage manufacturers who secure their robust, standardized and stackable returnable crates on pallets with string are ideal candidates for the Logomatic 850 PSC.

However, the system is also suitable for labeling in industries outside the beverage sector, where stable packaging such as cartons or crates are palletized in flush, uniform stacks and secured with string.

Labeling and securing: dual functionality saves process time

The Logomatic 850 PSC is an alternative to the highly successful Logomatic 920 PSCK, which has seen numerous installations since its launch in 2013. The new labeling system offers the following performance characteristics:

Labeling with one label: 120 pallets/hour

Labeling with two labels (front/side): 90-100 pallets/hour

Labeling with two labels (side/back): 100-110 pallets/hour

Labeling with three labels (front/side/back): 70 pallets/hour

The system supports A5-sized labels (150mm x 210mm), with 65mm of the label folded around the tamper-evident strip, allowing application on up to three sides. This is achieved by a telescopic applicator with an effective reach of 550 mm and continuous height adjustment, ensuring fast and accurate labeling on all required surfaces.

The Logomatic 850 PSC has a print speed of 300 mm per second and can handle label rolls of more than 800 m in length for extended changeover intervals. Label roll diameters up to 400 mm are supported.

During operation, a single label is printed and applied in less than 10 seconds, so the system's dual functionality offers significant process time savings. Label readability is verified by 100% code verification directly at the applicator, with automatic replacement of faulty labels.

Debuting at BrauBeviale, the Logomatic 850 PSC offers efficient and sustainable labeling solutions for pallets of returnable beverage crates.

The benefits at a glance:

Residue-free labeling: Folded label sticks only to itself - no adhesive residue

Sustainability: Cord made from recycled textile fibers, linerless labels (FSC certified)

Efficiency: Attach cord and label in one step

Flexibility & performance

Get in touch with me for a personal consultation!

- Lars Thuring, Senior Manager Strategy & Product Management

-über-Wi-Fi-HaLow-400.webp)