What are Labeling Machines?

A labeling machine is designed to apply and dispense labels to various products, containers, or packages. The main purpose of a labeling machine is to affix labels that provide essential information, such as product names, ingredients, and expiration dates. This enables product identification, branding, track and traceability, as well as legal compliance. Some labeling machines can also produce labels, in addition to applying them.

Labeling machines are an important part of every industry that requires product labeling. These machines are commonly used in the following industries: Food and beverage, pharma and chemical industry, cosmetic manufacturing, electronics and battery industry, agriculture, and construction.

What Kinds of Labeling Machines Are There?

In the labeler industry, labeling machines are typically either categorized as label dispensers or label printing dispensers. Label dispensers can only apply labels to products and packaging. Label printing dispensers can print and apply labels. Labeling machines are classified according to five main factors: The degree of automation, the labeling application method, the label type, and the running direction of the container and machine.

Degree of Automation

Depending on the level of automation, companies can choose between manual labelers, semi-automatic labeling machines, and automatic labeling machines.

Manual labelers are simple, hand-operated devices used to manually apply labels to products. They are not electrically powered. They are often used in small-scale operations or for labeling tasks that do not require high throughput. The operator is required to physically handle the product and label in order to align them.

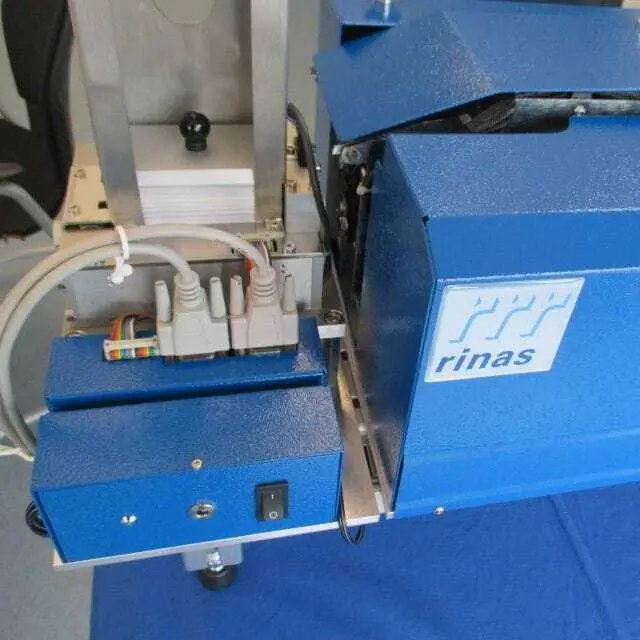

Semi-automatic labeling machines offer increased labeling efficiency but still require operator involvement. These machines are tabletop equipment and are designed to apply labels to the top or bottom surface of a product. The operator must place the product in a designated area or fixture, so that the machine can apply the label, often using vacuum pumps. The labeling application process is initiated and controlled via a foot pedal or hand switch.

Automatic labeling machines are used for large-scale and high-speed production. These machines can operate continuously with minimal human intervention. Operators are only required to place the labels reels into the machine. Automatic labelers work by integrating with the production or packaging line, where products are transported via conveyor belts. As products pass through the labeling station, sensors detect their presence and automatically apply the labels with precision.

Labeling Application Method

There are four different application methods: side labeling, wrap-around labeling, corner wrap labeling, or top & bottom labeling.

Side labeling machines are designed to apply labels to the front, back, or the sides of a product or packaging. Labels can be applied to more than one side. These machines are typically used for labeling rectangular or cylindrical objects, such as bottles and boxes.

Wrap-around labeling machines are specifically designed for cylindrical products, such as bottles, cans, and jars. These machines wrap a label completely around the circumference of the product. This enables a 360-degree coverage.

Corner wrap label applicators are used to apply labels around the corner of a product, such as the edge of a box or carton. This method is particularly useful for labeling cases or shipping boxes, where the label needs to be visible on two adjacent sides. This labeling method is commonly used to enable tamper-evident labeling.

Top & bottom labeling machines are designed to apply labels to both the top and bottom surfaces of a product simultaneously. These machines are commonly used for flat or slightly curved products such as trays, boxes, and containers.

Label Type

There are four main types of labeling machines according to label type. These are the self-adhesive labeling machine, wet glue labeling machine, shrink sleeve labeling machine, and the hot melt glue labeling machine.

Self-adhesive labeling machines, also called pressure-sensitive labelers are designed to apply labels that have an adhesive backing. These labels are supplied on a roll and are ready to stick to the product surface upon contact. The adhesive properties of the label ensure it sticks firmly to the product's surface.

Wet glue labeling machines use liquid glue to apply paper labels to products. As the product passes through the machine, a roller or brush applies a thin layer of liquid glue to the back of the label. The label is then pressed onto the product, and the glue secures it in place.

Shrink sleeve labeling machines are designed to apply shrink sleeves, which are plastic labels that fit around the entire circumference of a product and shrink to its shape when heat is applied. This type of labeling enables full-body labeling and is ideal for products with unique shapes or those requiring tamper-evident packaging.

Hot glue labeling machines use hot adhesive to apply labels to products. As the product moves along the conveyor, hot melt adhesive is applied to the back of the label using a heated roller or nozzle. The label is then immediately pressed onto the product, and the hot glue solidifies to secure it in place.

Running Direction of the Container

Labeling machines can either be vertical labeling machines or horizontal labeling machines. Vertical labeling machines are designed to apply labels to products that are transported in an upright or vertical position. Horizontal labeling machines are designed to apply labels to products that are transported in a horizontal position.

Running Direction of the Machine

This subcategory is divided into inline labeling machines and rotary labeling machines. Inline labeling machines are designed to be integrated into existing production lines, where products move along a conveyor system in a straight line. Rotary labeling machines utilize a rotating mechanism to position products for labeling. In these machines, products are placed on a rotating carousel or turret that moves them through various labeling stations in a circular motion.

Labeling Machines Products

What are Labeling Systems?

Labeling machines are part of labeling systems. A labeling system refers to the entire setup or process used for applying labels to products, packages, or containers. It includes not only the machinery involved but also the software, hardware, and processes that work together to achieve efficient and accurate labeling.

A labeling system includes labeling machines, label software, printers (thermal transfer, injet, or laser), converyors and handling equipment, sensors and cameras, and programmable logic controllers (PLCs). Label software is used to create different label types, such as QR codes, RFID labels, barcodes, and data matrix codes. RFID labeling systems are used to produce, print, and apply RFID labels, for example.