RFID Yarn in Uniforms

The French railroad company SNCF has been ordering uniforms for its employees from French manufacturer Cepovett for decades. What is new is that the first uniforms with embedded RFID yarn will be delivered from 2024. The pilot project which involves a quantity of 40,000 uniforms.

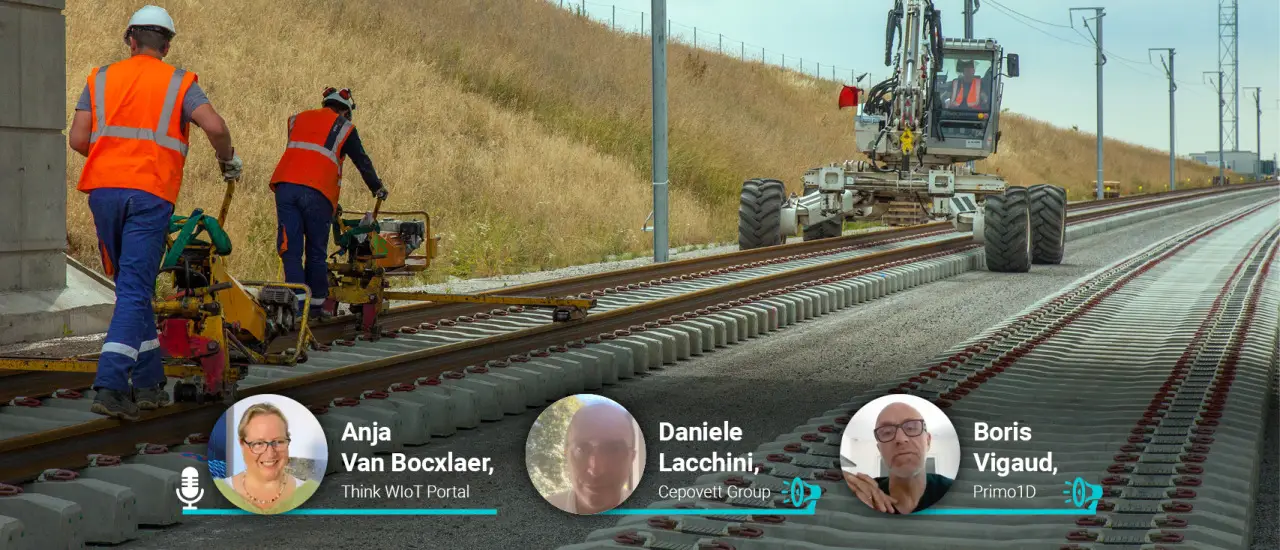

The pilot project is currently in the start-up phase and will enable SNCF to manage its uniforms inventory in real time. In this interview, Daniele Lacchini, Key Accounts and Services Project Manager at the Cepovett Group, and Boris Vigaud, CEO of Primo1D, explain the benefits for SNCF. Why is RFID yarn suitable for integration into garments and how many wash cycles can they withstand?

1. Daniele, could you briefly outline what services and products Cepovett offers?

Cepovett is a French family-run company. We specialize in the manufacture of uniforms and workwear. Cepovett is a European leader in the production of workwear. The international Cepovett Group delivers a total of 11 million garments per year. 40 percent of these are for major customers such as SNCF.

2. What is the project for SNCF about?

The project aims to optimize the traceability and inventory management of SNCF uniforms by integrating E-Thread RFID tags. Identification via RFID makes it possible to allocate uniforms to their respective wearers more efficiently and to better manage the flow of clothing during all handling phases (delivery, cleaning, storage, repair, maintenance, recycling).

The main objective of the project is to create improved traceability and optimized solutions for customer service. To be more specific, we want to be able to closely monitor the various stages of the entire process.

We also want to open up future-oriented perspectives, for example by exchanging information with various technical players such as manufacturers, laundries and recycling companies. Our aim is to build a kind of global infrastructure based on RFID technology.

3. One more question for you, Daniele: What advantages does SNCF expect from “RFID in uniforms”?

Daniele Lacchini started in the textile department at Cepovett Group in 2011. It is interesting to note that he worked both as Key Account Manager and Key Account Department Manager. He has held these positions for 12 years.

SNCF will initially be using RFID technology exclusively, i.e. the unique number of each item of clothing garment stored on the RFID tag. This will allow SNCF to track and monitor the uniforms. The time saved in all handling and logistics processes is enormous, since all processes can be automated. In addition to saving time, which is SNCF's top priority, the RFID yarn also offers other advantages.

The E-ThreadTM RFID yarn is resistant to high temperatures and mechanical stress. As the RFID label is discreetly integrated as a thread directly into the fabric, the wearing comfort of the uniform is not affected.

In addition, the label cannot be removed or tampered with. This ensures traceability and inventory management. Conclusion: The direct integration of the RFID thread enables the continuous and reliable tracking of uniforms throughout their entire lifecycle, from production and use, to disposal or recycling.

SNCF will initially be using RFID technology exclusively, i.e. the unique number of each item of clothing garment stored on the RFID tag. This will allow SNCF to track and monitor the uniforms. The time saved in all handling and logistics processes is enormous, since all processes can be automated. In addition to saving time, which is SNCF's top priority, the RFID yarn also offers other advantages.

The E-ThreadTM RFID yarn is resistant to high temperatures and mechanical stress. As the RFID label is discreetly integrated as a thread directly into the fabric, the wearing comfort of the uniform is not affected.

In addition, the label cannot be removed or tampered with. This ensures traceability and inventory management. Conclusion: The direct integration of the RFID thread enables the continuous and reliable tracking of uniforms throughout their entire lifecycle, from production and use, to disposal or recycling.

Daniele Lacchini started in the textile department at Cepovett Group in 2011. It is interesting to note that he worked both as Key Account Manager and Key Account Department Manager. He has held these positions for 12 years.

We are currently undergoing an initial test phase, which is expected to last until the end of 2025 if everything goes according to plan. That may seem like a long time, but you have to bear in mind that we are talking about equipping more than 70,000 carriers, which is a considerable number. That is why we want to make sure that no mistakes are made. If all goes well, we hope to convince SNCF of the benefits of the project and integrate RFID functionality from 2026.

RFID Technology in Textile Threads

4. Boris, how does the RFID yarn work?

Our product differs in that we use the same chip as conventional RFID solutions, but we have developed a manufacturing process to integrate it into textile yarn with a high level of RFID performance.

The final product is the result of intensive research and development, for which we have 26 different patents for the protection of our intellectual property.

We are the only ones in the world who can integrate RFID chips into a yarn that can withstand numerous washing cycles.

The special form factor of the E-Thread RFID tags allows the RFID functionality to be integrated discreetly and invisibly at any area of the garment. They can be integrated when manufacturing a garment under overlock stiches with a standard overlock machine or inserted under thermopatch labels. Once integrated, E-Thread RFID tags are completely invisible.

Features of an RFID Yarn?

I’ve been CEO of Primo1D since April 2024. Primo1D is actually still a startup, since the biggest challenge was to produce the RFID thread industrially and in large quantities. We’ve achieved this. Now, we focus on all customers who want to fully map the lifecycle of textile products. It is our goal to open new paths for the textile lifecycle.

E-ThreadTM RFID tags offer a distinct advantage over competitors by being fully embedded within the product, very performant and designed to withstand washing, harsh environments and high temperatures.

RFID is a very common and well-known technology. More than 40 billion RFID chips are sold worldwide every year. What makes our product unique is that we can easily integrate the chip into textile yarn. This yarn can withstand the stress of numerous washing cycles.

This is especially important for garments and distinguishes our product from the traditional RFID labels. The product can withstand around 100 domestic washing cycles and about 50 washing cycles in industrial settings.

E-ThreadTM RFID tags offer a distinct advantage over competitors by being fully embedded within the product, very performant and designed to withstand washing, harsh environments and high temperatures.

RFID is a very common and well-known technology. More than 40 billion RFID chips are sold worldwide every year. What makes our product unique is that we can easily integrate the chip into textile yarn. This yarn can withstand the stress of numerous washing cycles.

This is especially important for garments and distinguishes our product from the traditional RFID labels. The product can withstand around 100 domestic washing cycles and about 50 washing cycles in industrial settings.

I’ve been CEO of Primo1D since April 2024. Primo1D is actually still a startup, since the biggest challenge was to produce the RFID thread industrially and in large quantities. We’ve achieved this. Now, we focus on all customers who want to fully map the lifecycle of textile products. It is our goal to open new paths for the textile lifecycle.

5. Boris, what are the advantages of RFID yarn?

The main advantage is certainly the form factor and the easy integration directly into the garment during manufacturing. The RFID thread cannot be removed, which means that it can remain on the garment throughout its entire lifecycle. It also exhibits a negligible carbon footprint and will help the recycling of the textile material at end of life, without affecting the recycling process neither the quality of the recycle textile fiber.

The wash resistance of our tag is a game-changer, enabling identification of garments throughout their entire lifecycle, right up to recycling. This unlocks significant opportunities, especially in advancing the circular economy. Given that the textile industry is one of the most polluting, our tags provide a powerful solution to meet this critical challenge.

Future Outlooks

6. Daniele, is it possible to integrate clothing cabinets or self-service clothing boxes into the project?

We're going to create databases in which product information will be stored. Each product will then have a unique identification number and will be clearly identifiable. The use of these databases carries certain psychological stakes. Customers like to use their data exclusively and see it as their property, and the same is often true of their suppliers.

I believe that the future will be based on sharing this data, protected against certain malicious attacks, but freely available to the various parties involved in a project. Sharing data, or access to information raises fears of unauthorized access, or even espionage. We will therefore have to convince as much as work on the technical aspects.

7. Daniele, what is the future of textile manufacturing?

I am sure that in a few years, we will have to document the entire lifecycle of a garment. This starts with the raw material through delivery, the entire usage period, through to disposal, and the recycling and reproduction. In order to carry out this process efficiently and rationally on the basis of material information, the garment must be clearly identifiable. It basically comes down to a matter of documenting and calculating the entire lifecycle of each garment. I assume that manufacturers will lay the foundation for lifecycle mapping in the future.

8. Daniele, what do you see as the challenges for customers that want to engage with RFID technology?

We will build a database in which the product information is stored. Each product then has a unique ID and is therefore clearly identifiable. This database has a certain psychological aspect. Customers like to use their data exclusively and consider it to be their property. However, we want the product data to be shared. Sharing the data, or access to information creates the fear of unauthorized access or even espionage.

-über-Wi-Fi-HaLow-responsive.webp)