Workwear Available for Use in Any Situation

Workwear Management

The German Red Cross in Schwenningen uses an RFID cabinet system to manage workwear.

The GRC local society in the town of Schwenningen uses an RFID cabinet system to manage workwear. The management software stores how many items of clothing each employee is allowed to withdraw. Employees can access the clothing using an RFID membership card. The badge is scanned at the cabinet door, which is then authorized for opening. Employees can freely select the required size and withdraw the workwear.

The workwear itself is equipped with RFID tags so that its removal is registered in the management software. Used workwear is returned by depositing it at the flap of an RFID-enabled return cabinet. The RFID tag of each garment is captured and the return registered in the system.

The laundry pool is accessed by 70 volunteers and 3 part-time ambulance staff. The number of deployments varies greatly. While a mission in the area of emergency response or blood donation takes place once or twice a month, the ambulance service is deployed twice a week on average and the patient transport service is deployed every night. The number of personnel required also varies from two to ten, depending on the mission. In the case of ambulance services for major events, the number of volunteers deployed can rise to as many as 30. Equipping the volunteers with the necessary workwear must be ensured for each deployment.

The GRC local society in the town of Schwenningen uses an RFID cabinet system to manage workwear. The management software stores how many items of clothing each employee is allowed to withdraw. Employees can access the clothing using an RFID membership card. The badge is scanned at the cabinet door, which is then authorized for opening. Employees can freely select the required size and withdraw the workwear.

The workwear itself is equipped with RFID tags so that its removal is registered in the management software. Used workwear is returned by depositing it at the flap of an RFID-enabled return cabinet. The RFID tag of each garment is captured and the return registered in the system.

The laundry pool is accessed by 70 volunteers and 3 part-time ambulance staff. The number of deployments varies greatly. While a mission in the area of emergency response or blood donation takes place once or twice a month, the ambulance service is deployed twice a week on average and the patient transport service is deployed every night. The number of personnel required also varies from two to ten, depending on the mission. In the case of ambulance services for major events, the number of volunteers deployed can rise to as many as 30. Equipping the volunteers with the necessary workwear must be ensured for each deployment.

The German Red Cross in Schwenningen uses an RFID cabinet system to manage workwear.

Over 300 Garments Tagged with RFID

RFID Tagging of Workwear

The RFID laundry tag is patched into a piece of fabric and thermomechanically printed into the clothing. The tags are applied to the collars of workwear tops like sweaters, polo shirts and jackets, as well as to the waistband of workwear pants, and are applied by a textile services company in Schwenningen, which is also responsible for washing the workwear.

The glued-in RFID tags are flexible and designed to withstand up to 250 wash cycles and not to interfere with employees wearing the clothing.

Smart RFID Cabinet System

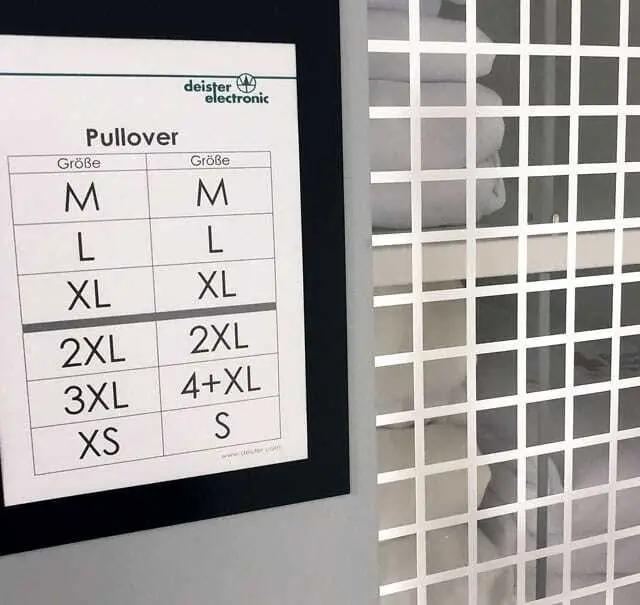

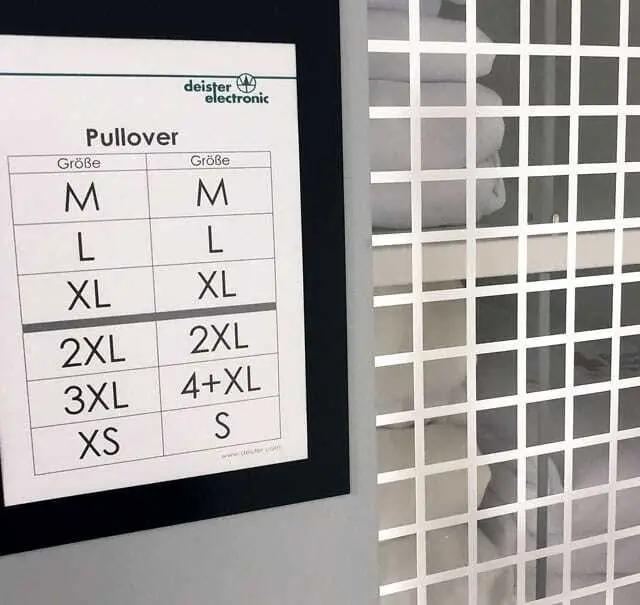

The workwear is registered in the GRC local society's management software using RFID and stored in four cabinets – one cabinet each for polo shirts, sweaters, jackets and pants. The fifth cabinet has a drop flap for the return of used workwear. This accumulates in a laundry bag in the cabinet. Both the storage cabinets and the return cabinet are RFID-enabled.

RFID tags are read both when clothes are withdrawn and when they are returned using RFID readers mounted on the cabinets. These capture the number of garments available as well as the fill level of the laundry bag in the return cabinet. This is displayed in the management system and the timely replenishment of fresh workwear and emptying of the return cabinet is possible.

Clothing Withdrawal with RFID-enabled Member ID Cards

The RFID reader on the cabinet door identifies the RFID chip in the member ID card and the door opens.

An RFID-enabled member ID card is held up to the cabinet door for the withdrawal of the workwear. The RFID reader on the cabinet door identifies the RFID chip in the member ID card and the door opens. The member ID cards have already been in use at the GRC in Schwenningen since the acquisition of an RFID-enabled key cabinet and have been expanded to include the clothing withdrawal application.

During the withdrawal process, the withdrawn item of clothing is booked to the account of the corresponding GRC member on the basis of the RFID tag on the ID card. When the item is returned, the member's account is credited and the quota for fresh clothing is available again.

An RFID-enabled member ID card is held up to the cabinet door for the withdrawal of the workwear. The RFID reader on the cabinet door identifies the RFID chip in the member ID card and the door opens. The member ID cards have already been in use at the GRC in Schwenningen since the acquisition of an RFID-enabled key cabinet and have been expanded to include the clothing withdrawal application.

During the withdrawal process, the withdrawn item of clothing is booked to the account of the corresponding GRC member on the basis of the RFID tag on the ID card. When the item is returned, the member's account is credited and the quota for fresh clothing is available again.

The RFID reader on the cabinet door identifies the RFID chip in the member ID card and the door opens.

Monitoring of Workwear

Proactively Prepared Workwear

With the RFID solution, it is possible to accurately document the loss and deterioration of clothing.

By using the RFID cabinet system, the GRC records the amount of fresh clothing and dirty laundry available. Hygiene is increased because fresh clothing is available to all emergency personnel at all times. Based on the usage and laundry cycles, it is also possible to see exactly which clothing size is most in demand.

A proactive provision of these clothing sizes in larger quantities takes place. The RFID system also makes it quick and easy to issue workwear to new members with an RFID-enabled membership card.

Wear and Tear of Workwear Documented

With the RFID solution, it is possible to accurately document the loss and deterioration of clothing. The deployment jackets and pants, for example, have reflective strips that undergo wear and tear as a result of the washing and disinfection process.

Approximately 70 wash cycles are possible before a change of clothing is required. Documentation of the number of wash cycles and the use of the workwear has not been possible to this extent until now. Demand-based planning for the acquisition of new workwear is being implemented.

By using the RFID cabinet system, the GRC records the amount of fresh clothing and dirty laundry available. Hygiene is increased because fresh clothing is available to all emergency personnel at all times. Based on the usage and laundry cycles, it is also possible to see exactly which clothing size is most in demand.

A proactive provision of these clothing sizes in larger quantities takes place. The RFID system also makes it quick and easy to issue workwear to new members with an RFID-enabled membership card.

Wear and Tear of Workwear Documented

With the RFID solution, it is possible to accurately document the loss and deterioration of clothing. The deployment jackets and pants, for example, have reflective strips that undergo wear and tear as a result of the washing and disinfection process.

Approximately 70 wash cycles are possible before a change of clothing is required. Documentation of the number of wash cycles and the use of the workwear has not been possible to this extent until now. Demand-based planning for the acquisition of new workwear is being implemented.

With the RFID solution, it is possible to accurately document the loss and deterioration of clothing.