Central workshop of the Belgian railway company

Central Workshop in Mechelen

Mechelen is a city between Brussels and Antwerp in northern Belgium. Inside the 13th-century St. Rumbold’s Cathedral is an imposing altar and a work by Flemish artist Anthony van Dyck.

In 1835, one of the first steam-powered railway lines in Europe began operation between Mechelen and Brussels. Today, the central workshop of the Belgian railway company SNCB/NMBS is located in Mechelen.

Mechelen is a small and picturesque city that is big on charm and history, thriving with quaint shops, car-free areas and pleasant little squares. The grace of centuries-old palaces and majestic churches appeals to everyone. There are no less than 336 listed buildings and monuments, including eight gothic and baroque churches from the 14th-17th century.

In the central workshop, essential train components are overhauled. This includes wheelsets, brake controllers, distributors, AC3D units and load proportioning valves. In addition, NMBS/SNCB tests train converters at 3,000 volts in a new high-voltage testing laboratory.

In 1835, one of the first steam-powered railway lines in Europe began operation between Mechelen and Brussels. Today, the central workshop of the Belgian railway company SNCB/NMBS is located in Mechelen.

Mechelen is a small and picturesque city that is big on charm and history, thriving with quaint shops, car-free areas and pleasant little squares. The grace of centuries-old palaces and majestic churches appeals to everyone. There are no less than 336 listed buildings and monuments, including eight gothic and baroque churches from the 14th-17th century.

In the central workshop, essential train components are overhauled. This includes wheelsets, brake controllers, distributors, AC3D units and load proportioning valves. In addition, NMBS/SNCB tests train converters at 3,000 volts in a new high-voltage testing laboratory.

Mechelen is a city between Brussels and Antwerp in northern Belgium. Inside the 13th-century St. Rumbold’s Cathedral is an imposing altar and a work by Flemish artist Anthony van Dyck.

High Voltage Testing Areas

SNCB/NMBS Tests the Converters of the Trains at 3,000 Volts

In order to guarantee safe working conditions, companies must reliably ensure that only persons with appropriate training are allowed access to certain areas and facilities. The Belgian railway company SNCB/NMBS uses an RFID system from Turck to monitor access to the high-voltage test areas of its central workshop in Mechelen. This is where train units are maintained, rebuilt and overhauled. In a new laboratory, SNCB/NMBS tests the converters of the trains at 3,000 volts.

In Belgium, the overhead lines for the trains carry a DC voltage of 3,000 volts. Power converters in the trains convert the high voltage into lower voltages for the drives, air conditioning and other equipment.

"The risks of a 3,000 V installation should not be underestimated. Even when the power is off, there can still be charge in coils and capacitors. That's why the work must always be done systematically, in accordance with established procedures, and by people who are aware of the risks."

The entrances to SNCB/NMBS's high-voltage test room can only be opened by authorized employees using an RFID tag.

Laboratory Power Supply Delivers 3,000 Volts

"In the new lab, we have three test zones to test the converters after they have been overhauled or repaired," Honee explains. "Many components can be tested at lower voltages, but for the final test we use a laboratory power supply that can deliver 3,000 V, just like the overhead line." The tests must be carried out in accordance with strictly regulated procedures, paying close attention to safety risks.

SNCB/NMBS asked the Belgian system integrator Dymotec – specialists in industrial electrical installations and automation – to develop a system capable of managing the test procedures in compliance with all the required safety aspects and to control access. The management of authorizations and the tracking of all processes are crucial here.

RFID System Secures Access to the Test Area

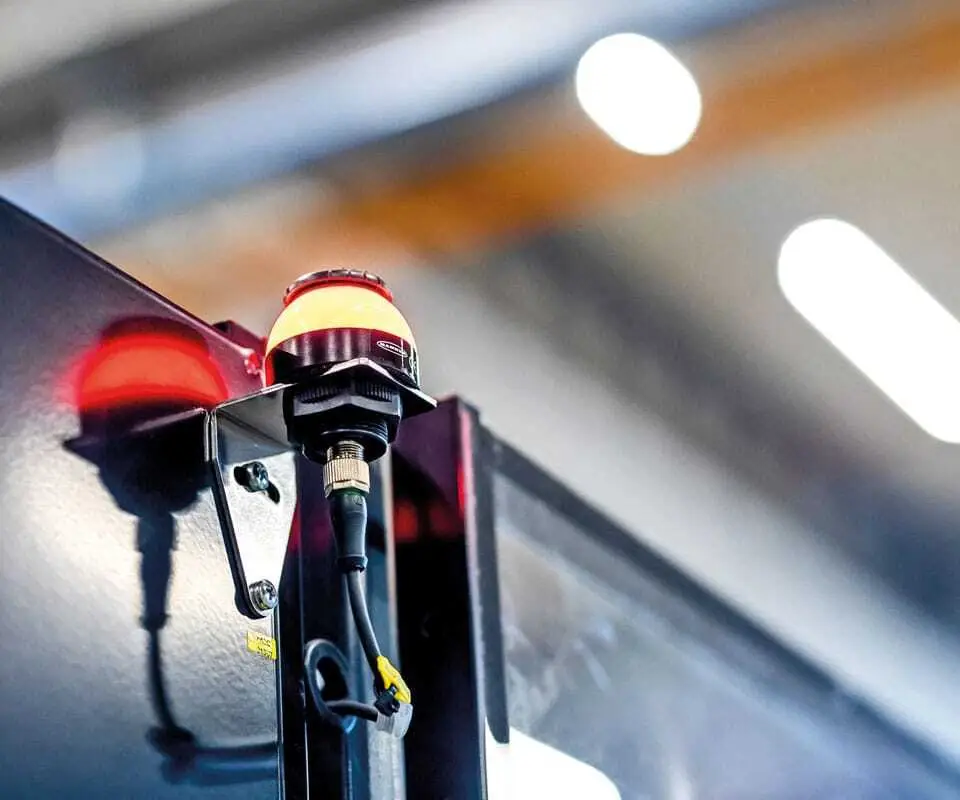

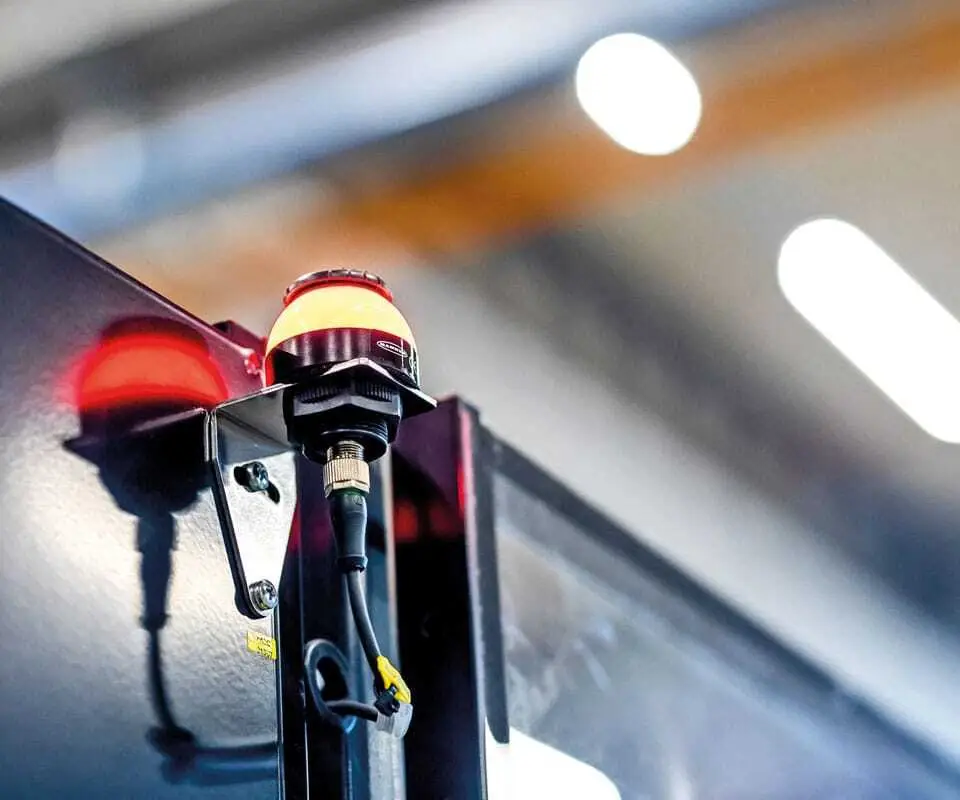

LED Indicators Showing the Status of a Zone

The K50 LED indicator with an acoustic signal changes to red as soon as the test procedure is active.

Type K50 LED indicators, which change color depending on the status of a zone, are installed at the entrance to the test areas in the laboratory. Each door as well as the control desks is provided with an RFID reader, at which the operators must present for reading their ID card, an RFID data carrier, in order to gain access.

"Our employees receive training to cover all the safety aspects of each type of converter," says Kristof Honee. "Dymotec's system ensures that all safety and security requirements are met at every step of the testing process."

Type K50 LED indicators, which change color depending on the status of a zone, are installed at the entrance to the test areas in the laboratory. Each door as well as the control desks is provided with an RFID reader, at which the operators must present for reading their ID card, an RFID data carrier, in order to gain access.

"Our employees receive training to cover all the safety aspects of each type of converter," says Kristof Honee. "Dymotec's system ensures that all safety and security requirements are met at every step of the testing process."

The K50 LED indicator with an acoustic signal changes to red as soon as the test procedure is active.

RFID Reader Devices Check Who is Logging In

The test procedure can be started after the RFID tag is scanned by the TN-M30-IOL-H1141 read/write head.

The RFID reader devices check who is logging in. The PLC checks whether this person is authorized to have access in a certain situation or to start the next step of an operation.

Finally, the PLC controls the lab's power supply and ensures that the test setup is only turned on when the situation is safe. Operators must confirm each step so that nothing is overlooked.

The RFID reader devices check who is logging in. The PLC checks whether this person is authorized to have access in a certain situation or to start the next step of an operation.

Finally, the PLC controls the lab's power supply and ensures that the test setup is only turned on when the situation is safe. Operators must confirm each step so that nothing is overlooked.

The test procedure can be started after the RFID tag is scanned by the TN-M30-IOL-H1141 read/write head.

RFID Read/Write Heads and Indicator Lights

RFID Readers and Signal Indicators Are Connected

Turck IO Link Master TBEN-L5-8IOL is in charge of signal transmission.

Dymotec uses the RFID system from Turck for this task. The RFID read/write heads read the ID of a pass and transmit it to the PLC via IO-Link.

The TBEN-L5-8IOL IO-Link masters communicate with the PLC via Profinet. The masters form a line topology via the integrated two-port switch of the IO-Link modules, so that only one Profinet line needs to be routed from access door to access door, which in turn saves wiring work.

The test areas are equipped with K50 indicators from Banner Engineering, which are actuated by the PLC to change their color. Unlike conventional color signal indicators in a rod design, one indicator per entrance door is therefore sufficient. Programming need not be limited to the selection of a single color. The LEDs in the light can be controlled individually. The control units were equipped with indicators with a sound function, so that the system can also issue acoustic warning signals.

Thanks to the automation of the test facility, all safety procedures are now implemented effectively – without slowing down the processes through manual procedures. The complete traceability of each action is ensured throughout.

Dymotec uses the RFID system from Turck for this task. The RFID read/write heads read the ID of a pass and transmit it to the PLC via IO-Link.

The TBEN-L5-8IOL IO-Link masters communicate with the PLC via Profinet. The masters form a line topology via the integrated two-port switch of the IO-Link modules, so that only one Profinet line needs to be routed from access door to access door, which in turn saves wiring work.

The test areas are equipped with K50 indicators from Banner Engineering, which are actuated by the PLC to change their color. Unlike conventional color signal indicators in a rod design, one indicator per entrance door is therefore sufficient. Programming need not be limited to the selection of a single color. The LEDs in the light can be controlled individually. The control units were equipped with indicators with a sound function, so that the system can also issue acoustic warning signals.

Thanks to the automation of the test facility, all safety procedures are now implemented effectively – without slowing down the processes through manual procedures. The complete traceability of each action is ensured throughout.

Turck IO Link Master TBEN-L5-8IOL is in charge of signal transmission.

"The RFID system is very easy to implement. The RFID readers and the signal indicators are connected to IO-Link masters via IO-Link. These also provide power, so there's not a lot of wiring involved."

All entrances to the test room are reliably secured via Turck's RFID solution so that only authorized persons are granted access.

-über-Wi-Fi-HaLow-responsive.webp)