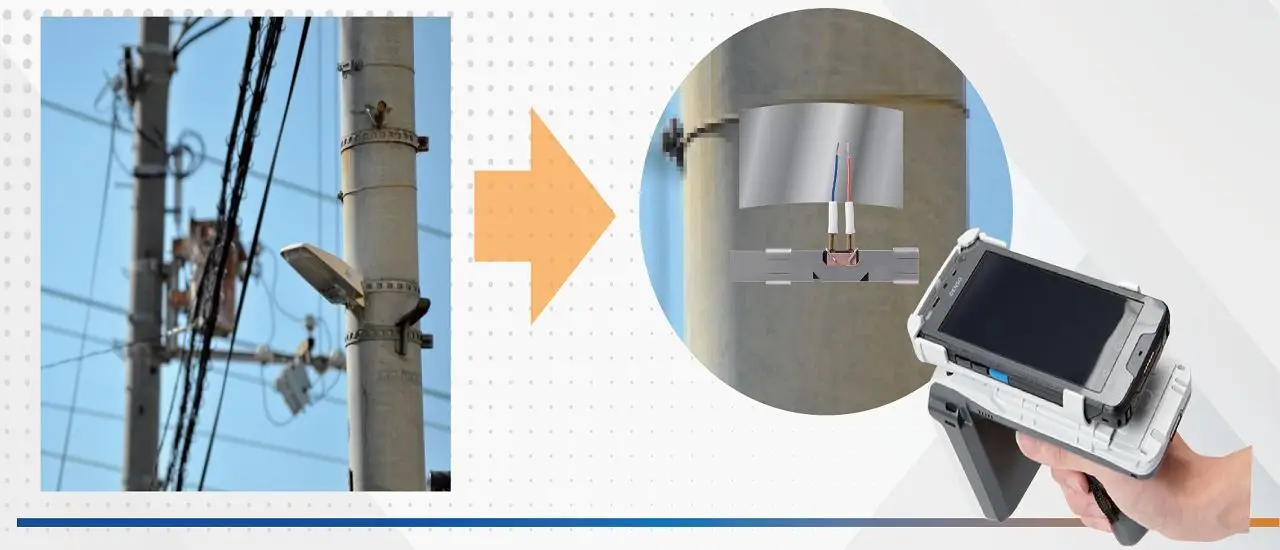

New Infrastructure Health Tag by E-Garde

Tag Based on Sacrificial Corrosion Protection for Steel Beams and Bridges

At a glance:

Tag detects conduction

Will detect corrosion in protective layers

Battery-less tag in UHF (840 MHz to 960 MHz)

Nominal tag lifetime of +20 years

In regions with substantial tectonic activity like Japan, the structural health of large buildings or bridges is usually monitored using strain sensors so as to detect cracks in buildings early on. However, it is also important to detect general corrosion as this also weakens the structural integrity of buildings. E-Garde has created an UHF RFID tag which performs this task on steel beams and posts. It will be launched in April 2024.

Sacrificial Corrosion Protection

E-Garde’s Infrastrucutre Health Tag detects electrical currents in metal structures which overlay the actual metal construction. These additional layers of metal are performing what is called sacrificial corrosion protection. They consist of highly active metal which will be corroded quicker than the metals they are protecting, which is why they are referred to as "sacrificial" metals. Corrosion in metals can be detected quickly as (partially) corroded metals are not as conductive as healthy metals. The method of using sacrificial metals is commonly used for detecting damages in the hulls of ships, water heaters, pipelines, distribution systems, above-ground tanks, underground tanks, and refineries. E-Garde introduces this as an easy-to-install RFID tag for other industrial uses, too.

Electricity Conduction Confirmation

This new tag could also be called Electricity Conduction Confirmation Tag, because this is what it does: the tag mechanism detects electrical currents based on resistance values in the sacrificial metal layer. The information which the tag transmits is determined by the value in a specific area of the tag memory. Changes to that value represent changes in conductivity.

Infrastructure Health Tag

Whilst the new tag mainly monitors corrosion, it will also detect leaks and cracks. The metal structures of large buildings and bridges which have a nominal lifetime of 20 years or more are the main use cases. The tag is battery-less and will endure as long as the structure it is attached to does. It can be powered whenever necessary by an RFID reader. Prototyping for the Infrastructure Health Tag started three years ago. It is about to be fully tested in a large municipality in Japan.