Interview with CEO Etsuro Inamoto

Innovative Product Developments in Japan

E-Garde has expanded its product offerings since 2007.

CEO Etsuro Inamoto talks about the innovative developments of the portfolio in an interview with RFID & Wireless IoT Global.

Inspired by the potential of RFID, Etsuro Inamoto founded E-Garde in 2007. The company has 50 employees and is based in Nihonbashi, Toyko. E-Garde delivers a wide range of RFID products to customers from various industries worldwide, many of which focus on access control applications. The goal is to expand the portfolio to cover IoT with Human-Machine Interfaces (HMI). All products are assembled in Japan and China. Parts are supplied from Japan, China and Europe.

"After the Tōhoku earthquake and the resulting nuclear disaster in 2011, we saw the importance of expanding our business abroad. Now, we serve customers worldwide."

Interview

CEO Etsuro Inamoto

1. Mr. Inamoto in 2007 you founded E-Garde. At that time, the company only produced smartcards. What outstanding events or milestones can you look back on in the company's 15-year history?

Inamoto: Since 2007, we have always been active in innovative product development. In 2010, we expanded our portfolio to include printing technologies. Between 2012 and 2014, we secured major OEM partnerships in Hong Kong and China, and introduced the production of silicon products and plastic housing designs.

Other milestones include a dual tag patent we obtained in 2015 and the launch of the wristband tag “Que Bangle” in 2016. Our first smart paper cards were sold to the North American market in 2018. In 2021, we developed the biodegradable paper smartcard. In 2022, we started producing printed circuit boards.

2. Can you briefly describe the product portfolio?

We have a diverse product range. We produce dual tags, hard tags, RFID sensor tags and RFID data loggers. We also have multi-functional smart paper and wooden cards, and a selection of RFID keycards, wristbands, and keyfobs.

3. What quality characteristics do the products meet?

Our RFID products are manufactured using sustainable, high-quality materials. All products produced are certified according to the international ISO 9001, ISO 14001 and ISO 27001 standards, and go through strict quality control. We comply with customer specifications, along with domestic and foreign laws and regulations to ensure that the products we supply meet customer expectations.

4. What innovative new developments has E-Garde launched?

We have recently launched two new ranges of sensor ICs. The first are the new acceleration sensor ICs which can synchronize the data transfer of more than 100 chips. The second are the battery-free capacitive sensor ICs that can sense temperature, moisture and pressure. These are suited for applications in water level, load, and screw loosening detection.

The capacitive sensor ICs can measure a minimum resolution of 0.1 pF and a maximum of 4,000 pF. The measurement range is between 0.1 and 100 pF.

5. Which development partners does E-Garde work with?

We are working closely with Japanese semiconductor manufacturer Lapis Technology on the joint development of capacitive sensor ICs and integrated UHF circuits. Development and performance inspections of the IC chips are conducted by E-Garde for every application.

We are also working on a project concerning the development of a unique IC chip in cooperation with the AutoID Lab at Keio University. Here, E-Garde is actively involved in the manufacturing and circuit design of RFID tags.

6. What role does sustainability play in product development?

Our mission is to save time, power and resources. In this sense, all product development at E-Garde is linked to sustainability. By utilizing RFID, we were able to improve working environments and productivity. We established a system for the management of chemical substances in our products. This way, we ensure that our products are free of regulated chemical substances. We also use materials that have a low environmental impact.

7. What will be new on the market in 2023?

In 2023, we plan to release two new products. The first is a quantity measurement sensor and the second is a capacitance measurement tag.

1. Mr. Inamoto in 2007 you founded E-Garde. At that time, the company only produced smartcards. What outstanding events or milestones can you look back on in the company's 15-year history?

Inamoto: Since 2007, we have always been active in innovative product development. In 2010, we expanded our portfolio to include printing technologies. Between 2012 and 2014, we secured major OEM partnerships in Hong Kong and China, and introduced the production of silicon products and plastic housing designs.

Other milestones include a dual tag patent we obtained in 2015 and the launch of the wristband tag “Que Bangle” in 2016. Our first smart paper cards were sold to the North American market in 2018. In 2021, we developed the biodegradable paper smartcard. In 2022, we started producing printed circuit boards.

2. Can you briefly describe the product portfolio?

We have a diverse product range. We produce dual tags, hard tags, RFID sensor tags and RFID data loggers. We also have multi-functional smart paper and wooden cards, and a selection of RFID keycards, wristbands, and keyfobs.

3. What quality characteristics do the products meet?

Our RFID products are manufactured using sustainable, high-quality materials. All products produced are certified according to the international ISO 9001, ISO 14001 and ISO 27001 standards, and go through strict quality control. We comply with customer specifications, along with domestic and foreign laws and regulations to ensure that the products we supply meet customer expectations.

4. What innovative new developments has E-Garde launched?

We have recently launched two new ranges of sensor ICs. The first are the new acceleration sensor ICs which can synchronize the data transfer of more than 100 chips. The second are the battery-free capacitive sensor ICs that can sense temperature, moisture and pressure. These are suited for applications in water level, load, and screw loosening detection.

The capacitive sensor ICs can measure a minimum resolution of 0.1 pF and a maximum of 4,000 pF. The measurement range is between 0.1 and 100 pF.

5. Which development partners does E-Garde work with?

We are working closely with Japanese semiconductor manufacturer Lapis Technology on the joint development of capacitive sensor ICs and integrated UHF circuits. Development and performance inspections of the IC chips are conducted by E-Garde for every application.

We are also working on a project concerning the development of a unique IC chip in cooperation with the AutoID Lab at Keio University. Here, E-Garde is actively involved in the manufacturing and circuit design of RFID tags.

6. What role does sustainability play in product development?

Our mission is to save time, power and resources. In this sense, all product development at E-Garde is linked to sustainability. By utilizing RFID, we were able to improve working environments and productivity. We established a system for the management of chemical substances in our products. This way, we ensure that our products are free of regulated chemical substances. We also use materials that have a low environmental impact.

7. What will be new on the market in 2023?

In 2023, we plan to release two new products. The first is a quantity measurement sensor and the second is a capacitance measurement tag.

CEO Etsuro Inamoto

Customized RFID Cards, Tags, Wristbands & Keyfobs

"E-Garde’s products are divided into two categories. The first: special tags including dual tags, hard tags, RFID sensor tags and RFID data loggers. The second: hotel cards and tags for access control applications including a range of RFID keycards, wristbands, and keyfobs."

Special Tags

RFID Sensor Tag by E-Garde

Dual Tags

- Operational Frequencies: HF (13.56 MHz), UHF (860-960 MHz)

- Long read ranges

- HF and UHF IC chips can be combined freely, allowing easy integration into existing systems with existing hardware.

Hard Tags

- Dimensions: 30 × 45 mm (teardrop) / 34 × 34 mm (square)

- Material: FR4

- Operating Temperature: -20 to 130 ℃

RFID Sensor Tags

- Dimensions: 42 × 92.5 mm / 39 × 81 mm

- Material: PET, Aluminum, ACP

- Operating Temperature: -25 ℃ to 60 ℃

- RFID Chip: MR7930 (UHF) / NTAG223 (HF)

RFID Data Loggers

- Dimensions: 98.5 × 59.0 × 20.5 mm

- Material: ABS (Housing), FR4 (Board), PC (Cover)

- Operating Temperature: -50 ℃ to 80 ℃

- Read Range: 4 to 6 m

Dual Tags

- Operational Frequencies: HF (13.56 MHz), UHF (860-960 MHz)

- Long read ranges

- HF and UHF IC chips can be combined freely, allowing easy integration into existing systems with existing hardware.

Hard Tags

- Dimensions: 30 × 45 mm (teardrop) / 34 × 34 mm (square)

- Material: FR4

- Operating Temperature: -20 to 130 ℃

RFID Sensor Tags

- Dimensions: 42 × 92.5 mm / 39 × 81 mm

- Material: PET, Aluminum, ACP

- Operating Temperature: -25 ℃ to 60 ℃

- RFID Chip: MR7930 (UHF) / NTAG223 (HF)

RFID Data Loggers

- Dimensions: 98.5 × 59.0 × 20.5 mm

- Material: ABS (Housing), FR4 (Board), PC (Cover)

- Operating Temperature: -50 ℃ to 80 ℃

- Read Range: 4 to 6 m

RFID Sensor Tag by E-Garde

Hotel Cards & Tags

RFID Wristband by E-Garde

RFID Keycards

E-Garde offers fully customizable RFID keycards for access control applications in hotels. The cards are available in three different materials: plastic, paper and wood. Both the paper and wooden cards are biodegradable. The company works in close cooperation with the hotel industry to develop tailor-made solutions with expert smartcard technology.

RFID Wristbands

The RFID Wristbands from E-Garde contain a tag that is specially designed for optimal performance on the human body. The RFID Wristbands enable hands-free, contactless access control to hotel rooms and amenities for both staff and guests. Cashless payment is also made possible. The company’s range of RFID wristbands include the Que Bangle, Fabric Wristband, Silicon Wristband, the Adjustable Wristband, and the single-use Paper Wristband.

RFID Keyfobs

E-Garde offers hotels RFID keyfobs that function as room keys. The keyfobs are available in small batches from 100 pieces. Different designs, colors and customizations are possible. The company’s RFID keyfobs include the Plastic Keyfob, Wooden Keyfob, Leather Keyfob and the Minica Tag.

RFID Keycards

E-Garde offers fully customizable RFID keycards for access control applications in hotels. The cards are available in three different materials: plastic, paper and wood. Both the paper and wooden cards are biodegradable. The company works in close cooperation with the hotel industry to develop tailor-made solutions with expert smartcard technology.

RFID Wristbands

The RFID Wristbands from E-Garde contain a tag that is specially designed for optimal performance on the human body. The RFID Wristbands enable hands-free, contactless access control to hotel rooms and amenities for both staff and guests. Cashless payment is also made possible. The company’s range of RFID wristbands include the Que Bangle, Fabric Wristband, Silicon Wristband, the Adjustable Wristband, and the single-use Paper Wristband.

RFID Keyfobs

E-Garde offers hotels RFID keyfobs that function as room keys. The keyfobs are available in small batches from 100 pieces. Different designs, colors and customizations are possible. The company’s RFID keyfobs include the Plastic Keyfob, Wooden Keyfob, Leather Keyfob and the Minica Tag.

RFID Wristband by E-Garde

The Latest RFID Developments in Japan

"E-Garde is actively involved in innovative RFID projects throughout Japan. The company offers a one-stop solution from planning, to design, to the mass production of custom RFID tags."

Lapis Technology

E-Garde is working closely with Lapis Technology on the joint development of capacitive sensor ICs and integrated UHF circuits.

Lapis Technology is a Japanese semiconductor manufacturer that belongs to the Rohm Group. Established in 2020 in Yokohama, Japan, the company develops and sells microcontrollers, video LSIs, speech synthesis LSIs, wireless LSIs, wireless charging LSIs, display drivers, and Liion cattery monitoring LSIs.

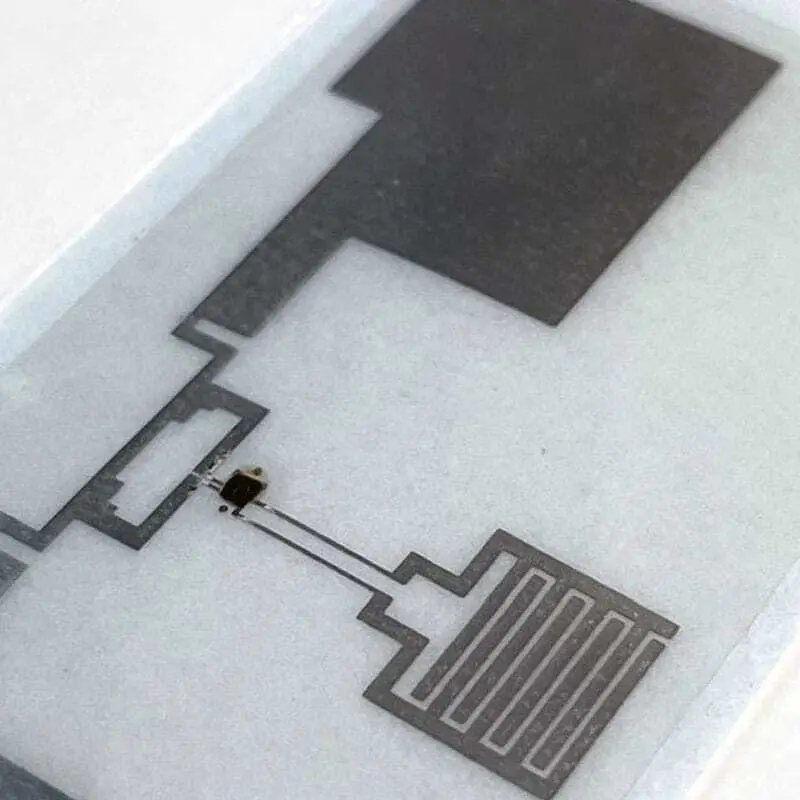

Capacitive Sensor ICs & Integrated UHF Circuits

E-Garde is working closely with Lapis Technology on the joint development of capacitive sensor ICs and integrated UHF circuits. The collaboration between both companies began in 2019. The unique capacitive sensor IC chip was developed by Lapis Technology.

E-Garde conducts development and performance inspections of the IC chip for applications including water-level detection, weight detection, moisture detection and gas detection. Tag communication is most effective when both chip and antenna characteristics match. Together with Lapis Technology, the company has been working on creating optimal IC communication characteristics based on market demands.

Further contributions to this project include the development and launch of new UHF integrated circuits. E-Garde’s comprehensive know-how in planning, design, prototyping, inlays, performance evaluation and mass production made the company a reliable partner in this project.

Lapis Technology is a Japanese semiconductor manufacturer that belongs to the Rohm Group. Established in 2020 in Yokohama, Japan, the company develops and sells microcontrollers, video LSIs, speech synthesis LSIs, wireless LSIs, wireless charging LSIs, display drivers, and Liion cattery monitoring LSIs.

Capacitive Sensor ICs & Integrated UHF Circuits

E-Garde is working closely with Lapis Technology on the joint development of capacitive sensor ICs and integrated UHF circuits. The collaboration between both companies began in 2019. The unique capacitive sensor IC chip was developed by Lapis Technology.

E-Garde conducts development and performance inspections of the IC chip for applications including water-level detection, weight detection, moisture detection and gas detection. Tag communication is most effective when both chip and antenna characteristics match. Together with Lapis Technology, the company has been working on creating optimal IC communication characteristics based on market demands.

Further contributions to this project include the development and launch of new UHF integrated circuits. E-Garde’s comprehensive know-how in planning, design, prototyping, inlays, performance evaluation and mass production made the company a reliable partner in this project.

E-Garde is working closely with Lapis Technology on the joint development of capacitive sensor ICs and integrated UHF circuits.

Water-Level Detection

A common application of the capacitive sensor IC is water-level detection.

A common application of the capacitive sensor IC is water-level detection. The sensor IC measures the capacitance of an object and detects its state. By attaching the detection electrode and sensor inlay to the exterior of a liquid container, it is possible to detect the change in liquid level. As the water level rises in the container, the area of the sensor electrode covered by water increases. The capacitive sensor tag then reads out the change in the indicated value.

Water levels can be detected even in opaque or colored containers, such as medicine or sake bottles. Water detection applications are widely used in factories and similar environments. The capacitive sensor IC does not require a power supply. Data is transmitted contactlessly via radio waves.

A common application of the capacitive sensor IC is water-level detection. The sensor IC measures the capacitance of an object and detects its state. By attaching the detection electrode and sensor inlay to the exterior of a liquid container, it is possible to detect the change in liquid level. As the water level rises in the container, the area of the sensor electrode covered by water increases. The capacitive sensor tag then reads out the change in the indicated value.

Water levels can be detected even in opaque or colored containers, such as medicine or sake bottles. Water detection applications are widely used in factories and similar environments. The capacitive sensor IC does not require a power supply. Data is transmitted contactlessly via radio waves.

A common application of the capacitive sensor IC is water-level detection.

Auto-ID Lab in Keio University

Auto-ID Lab in Keio University

The Auto-ID Lab was established at Keio University in January 2003 and is a Japan-affiliate of the Auto-ID Lab at MIT. The focus is to create an international standard for Auto-ID technology through research and experimentation.

At the SFC Open Research Forum (ORF) in 2017, the Auto-ID Lab at Keio University introduced its latest developments, including the MSMA concept, a group encoding of RFID that enables the identification of missing items, multi-code filtering and collection with mixed standards of RFID tags, and a product lifecycle management system.

The Auto-ID Lab was established at Keio University in January 2003 and is a Japan-affiliate of the Auto-ID Lab at MIT. The focus is to create an international standard for Auto-ID technology through research and experimentation.

At the SFC Open Research Forum (ORF) in 2017, the Auto-ID Lab at Keio University introduced its latest developments, including the MSMA concept, a group encoding of RFID that enables the identification of missing items, multi-code filtering and collection with mixed standards of RFID tags, and a product lifecycle management system.

Auto-ID Lab in Keio University

Together with the Keio University Auto-ID Lab, E-Garde is working on the development of a unique IC chip with Multi-Subcarrier Multiple Access (MSMA).

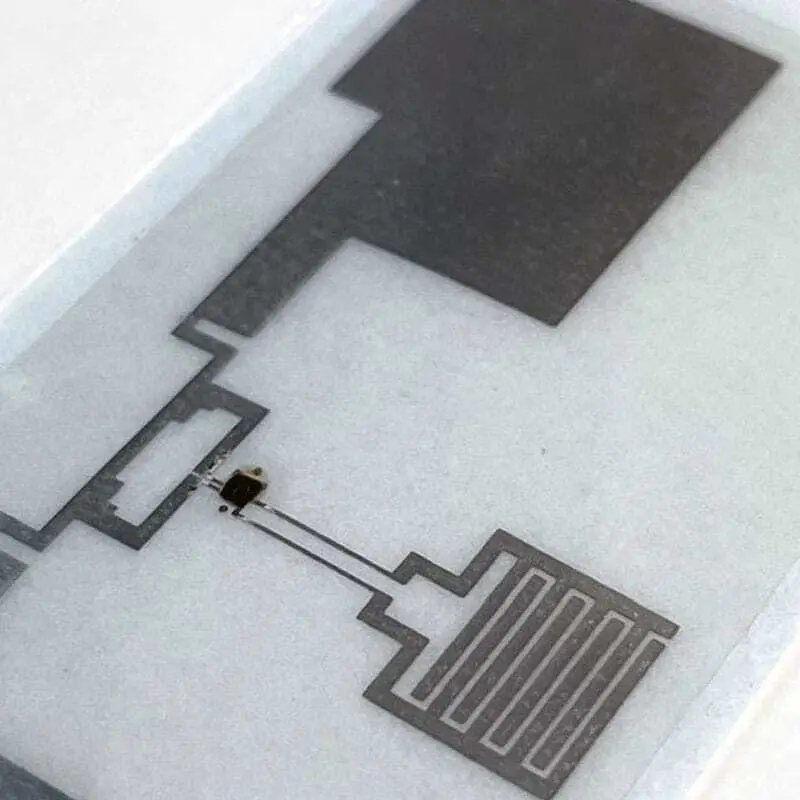

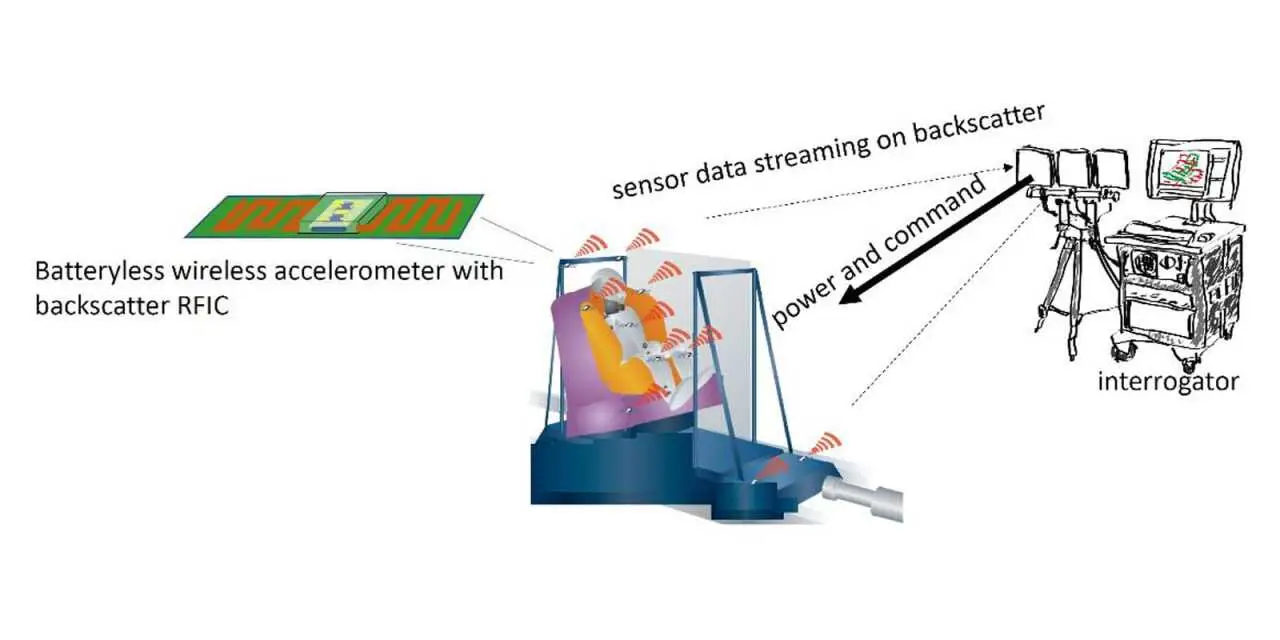

MSMA, RFID and RFICs

Together with the Keio University Auto-ID Lab, E-Garde is working on the development of a unique IC chip with Multi-Subcarrier Multiple Access (MSMA). The project is headed by Professor Jin Mitsugi from Keio University, who also developed the IC chip. E-Garde is actively involved in the manufacturing and circuit design of the RFID tags.

MSMA is an innovative wireless communication method that ensures that data collection at multiple points is fully synchronized. The system consists of an RFID tag and interrogator device that conforms to the Gen2 standard. The customized RFIC “Jupiter” is embedded in the RFID tag. Jupiter can be connected with any sensor chip that supports SPI and operates based on energy harvesting.

The RFID tag becomes a battery-less and wireless accelerometer with a backscatter RFIC. Sensor data is streamed on the backscatter and captured by the interrogator. The interrogator issues commands back to the sensors. The sensors harvest the energy from the interrogator as a source of power.

Use Cases

Use Case 1: Quantity Measurement in the Warehouse

E-Garde has been developing a batteryless quantity sensor in cooperation with the Rohm Group from Lapis Technology. The development of the IC chips for this project began in 2018. The IC tag used for the mass display system has been further developed since fall of 2022 and is currently being used in demonstration experiments in E-Garde’s own warehouses. In 2023, the ICs were launched in the market for the first time.

Accurate Inventories of Tools and Spare Parts

By placing the batteryless quantity sensors throughout its warehouse, E-Garde is able to target capture objects such as tools and spare parts. Items containing liquids can also be read without problems. Data capture is carried out via a reader/writer which senses the weight displacement based on the quantity of parts and liquid in one percent increments.

The software of the reader/ writer displays and records the quantity as data is being captured. By uploading the data to the server, the company is able to analyze trends such as the frequency of usage of target objects via spreadsheets. Additionally, the quantity sensor also has a function that alerts and manages orders. Installation is simple with little calibration and software setup. Since the system is batteryless and wireless, there is no power consumption during standby mode.

E-Garde has been developing a batteryless quantity sensor in cooperation with the Rohm Group from Lapis Technology. The development of the IC chips for this project began in 2018. The IC tag used for the mass display system has been further developed since fall of 2022 and is currently being used in demonstration experiments in E-Garde’s own warehouses. In 2023, the ICs were launched in the market for the first time.

Accurate Inventories of Tools and Spare Parts

By placing the batteryless quantity sensors throughout its warehouse, E-Garde is able to target capture objects such as tools and spare parts. Items containing liquids can also be read without problems. Data capture is carried out via a reader/writer which senses the weight displacement based on the quantity of parts and liquid in one percent increments.

The software of the reader/ writer displays and records the quantity as data is being captured. By uploading the data to the server, the company is able to analyze trends such as the frequency of usage of target objects via spreadsheets. Additionally, the quantity sensor also has a function that alerts and manages orders. Installation is simple with little calibration and software setup. Since the system is batteryless and wireless, there is no power consumption during standby mode.

By placing the batteryless quantity sensors throughout its warehouse, E-Garde is able to target capture objects such as tools and spare parts.

"Unlike ordinary weighing scales, the quantity indicator system is environmentally friendly and operates without batteries or wiring."

Use Case 2: Cold Chain Management with RFID

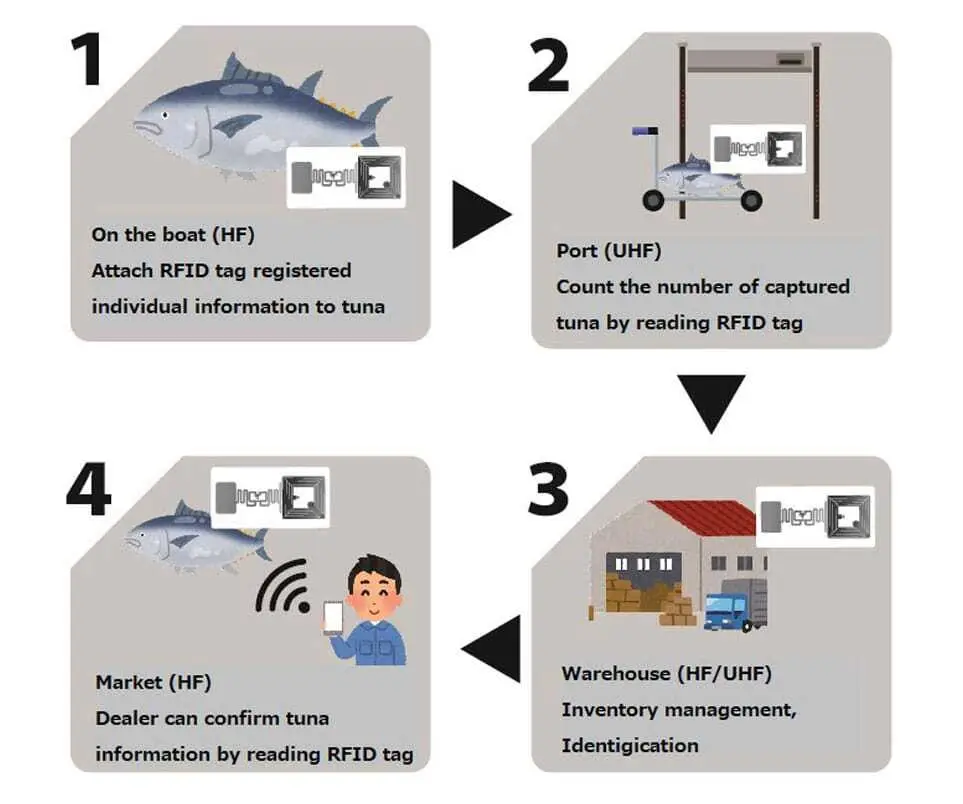

E-Garde's internationally patented dual-frequency tags were used for the management of freshly caught tuna in the ports of Misaki, Shimizu and Yaizu in Japan.

Japan has implemented food traceability systems since 2001 to ensure safe food consumption. Many projects have been developed to monitor the temperature, condition and quality of fresh produce and fish with the use of RFID and sensor technology. Information management systems have also been developed in Japan for the tracking of tuna from fishing vessel to the market via RFID that is implanted into the body of the fish.

Japan has implemented food traceability systems since 2001 to ensure safe food consumption. Many projects have been developed to monitor the temperature, condition and quality of fresh produce and fish with the use of RFID and sensor technology. Information management systems have also been developed in Japan for the tracking of tuna from fishing vessel to the market via RFID that is implanted into the body of the fish.

E-Garde's internationally patented dual-frequency tags were used for the management of freshly caught tuna in the ports of Misaki, Shimizu and Yaizu in Japan.

Tuna Management with RFID

E-Garde took part in an environmental demonstration experiment between 2014 and 2020 throughout Japan. The main ports involved were the ones in Misaki, Shimizu and Yaizu. Partners of the project included the Fisheries Agency of Japan, the Japan Tuna Association, the University of Marine Science and Technology, and some local fishing boats owners.

E-Garde provided its internationally patented dual frequency NFC/UHF RFID tags for this project. The tags are attached on the boat where the tuna is caught and are read out on the spot using a handheld terminal. Data such as the code of the fisherman, time of capture and GPS location of capture is captured. Once the ship returns to port, the RFID tags are read all at once in the UHF band and the number of captured fish is automatically sent to the server. When carving up the tuna, the dealer reads the RFID tag with a smartphone, outputs the QR code, and attaches it to the subdivided tuna packs.

Consumers read the tuna data from the QR code affixed to the tuna pack and food safety is thus guaranteed. The Tuna and Skipjack Association can also manage resources by collecting the data from the ships and comparing it with the data captured on land.

HF and UHF RFID is used on the fishing boat and in the warehouse. NFC is used by consumers at point of sale.