- Battery-free UHF RFID transponders transmit switching states and unique IDs to vehicle-mounted readers without local power.

- Vehicle-mounted readers capture signal data and forward it via TCP/IP, UDP, or serial interfaces to onboard systems.

- The system enables low-cost retrofitting of older vehicles without altering central control systems.

- Components meet rail-grade standards (EN 50155) and use the open ISO 18000-63 air interface.

- Applications extend to switch detection, precise positioning, and targeted lubrication to reduce wheel and track wear.

Many public transportation systems still rely on outdated infrastructure and mixed fleets of old and new vehicles. Older tram lines, for example, often operate alongside modern systems. Retrofitting these with state-of-the-art signaling technology is complex and expensive.

A wireless solution using UHF RFID readers from Feig Electronic and UHF RFID sensor transponders from smart-TEC now offers a low-maintenance and cost-effective alternative. This technology is already in use in cities such as Ankara, Hong Kong, and the Swiss Alps, where it has proven itself in harsh and variable environments.

Reliable UHF RFID Deployment in Railway Operations

Transitioning from Visual to Digital Signal Transmission

RFID technology offers a practical solution for digitizing signal systems within existing tram infrastructure. In older systems, train drivers must visually detect signals along the track—a process that can be optimized.

The solution: RFID enables automatic signal transmission to the vehicle. This eliminates reliance on line-of-sight or weather conditions, as visual detection becomes secondary. This approach not only opens up new opportunities for existing metro lines but can also be used in maintenance depots to modernize signal systems on-site with minimal effort.

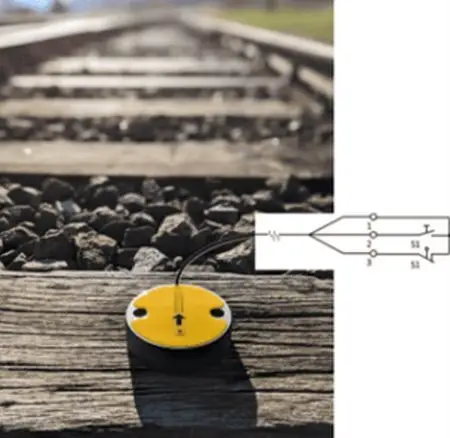

The key components of this system are battery-free UHF RFID sensor transponders. These are installed in the track bed or road surface and connected to the existing signaling infrastructure via a sensor cable. The cable itself can span several hundred meters.

This allows for flexible placement of the transponders without needing to install them directly next to the signal. The switching state can be transmitted to the vehicle from several meters away.

How the Signal Data Reaches the Train

When a vehicle passes over a sensor, a UHF RFID reader mounted on or beneath the vehicle detects the transponder. The signal is received via an antenna, also installed on the underside of the vehicle. The reader captures both the unique identifier (UID) and the current switching state of the associated signal. This data is transmitted to the vehicle’s control system via established interfaces such as TCP/IP, UDP telegrams, or serial communication.

The transmitted signal data can trigger internal alerts—such as visual or acoustic signals—to warn the driver, without requiring changes to the vehicle’s central systems. This makes the solution particularly well suited for retrofitting older vehicles within mixed fleets. The passive transponders and readers ensure reliable operation with minimal maintenance over extended periods.

Durable Readers for Demanding Railway Environments

Die Wirksamkeit dieser Lösung hängt von RFID-Lesegeräten ab, die für den Einsatz in mobilen und bahnspezifischen Umgebungen geeignet sind.

Der ID LRU4000X von FEIG Electronic ist ein solches UHF-RFID-Lesegerät, das in diesen Anwendungen eingesetzt wird. Es ist so konstruiert, dass es auch unter mechanischer Belastung, Vibration und Temperaturschwankungen zuverlässig funktioniert - Bedingungen, die typischerweise im Bahnbetrieb auftreten. In Kombination mit einer an der Unterseite des Fahrzeugs montierten Antenne ermöglicht es die lückenlose Erfassung von Transpondern an der Strecke.

Alle Komponenten erfüllen die Anforderungen der EN 50155 für elektronische Geräte in Schienenfahrzeugen. Auch beim Thema Luftschnittstelle ist die Lösung Konform zum ISO Standard 18000-63 und somit keine proprietäre Lösung von FEIG.

New Application Areas for Position and Switch Detection

In addition to signal transmission, RFID-based systems support further use cases in railway operations. On monorail systems in China, the technology detects switch positions and transmits this information to approaching vehicles. This enables early response to track changes and contributes to smoother operation.

The unique ID of each sensor transponder can also be linked to location data. This allows for precise vehicle tracking, regardless of tunnel conditions or adverse weather. The data supports functions such as real-time updates for passenger information systems and position-based automation.

Integrating RFID into Lubrication Systems to Reduce Wear

In the context of rail vehicle operation, the German company Rebs Zentralschmiertechnik uses UHF RFID technology to enhance the efficiency of its flange lubrication systems. These systems are designed to reduce wear and noise during curve travel—an important factor in both urban environments and mountainous regions.

Just as RFID is used for detecting signals or position markers in trackside infrastructure, it also plays a key role in operating these lubrication systems. UHF RFID readers installed on or beneath the trains detect position markers—transponders—embedded in the track bed.

This enables the system to activate lubrication only in specific areas, such as curves, where wheel wear is most significant. The system is controlled by transmitting position data from the passive RFID transponders to the vehicle's onboard systems.