Versatile and reliable: New BGL fork light barriers from Balluff

Optoelectronic Sensors

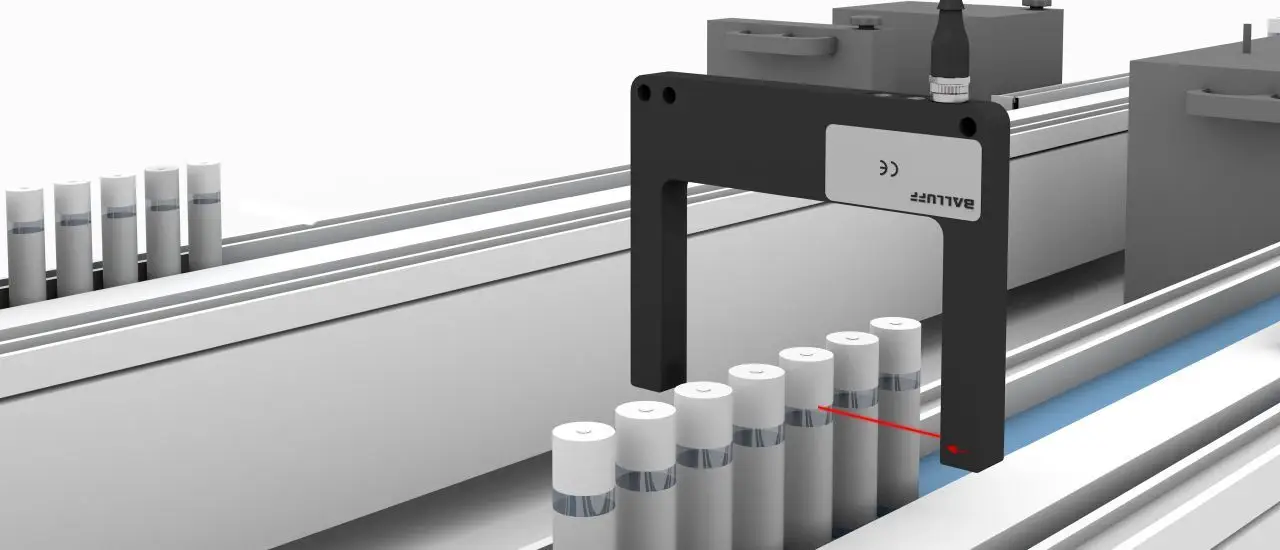

With a new generation of fork light barriers, sensors and automation specialist Balluff is expanding its portfolio of optoelectronic sensors. Customers from mechanical engineering, logistics, and the food industry benefit from a wide range of application possibilities – and easy integration.

Fork light barriers* are used not only for object detection, position monitoring, and process control but also in quality assurance. They stand out for their versatility and flexibility. This diversity makes them a suitable solution for various industrial requirements.

* Fork light barriers, also known as fork sensors or U-shaped photoelectric sensors, are optical sensors used for detecting objects that pass through their sensing area.

Four new products mark the launch of the third generation of the popular BGL series, which will gradually replace the previous models. In addition, the new BGL Entry series offers an optimized and cost-effective basic version.

- Susanne Rehrl, Product Manager, Balluff

Saving Time and Costs

As compact sensors, the BGL fork light barriers are pre-adjusted and combine the transmitter and receiver in a single housing. Thanks to plug-and-play functionality, they can be easily and directly integrated into existing systems and machines, saving both time and costs. In addition to straightforward installation, they offer high precision and reliability, as well as maximum stability in applications due to their extensive functional reserve.

BGL Entry has been available since February 2024. The first models of the new generation were launched at the end of 2024, with additional variants expected to complete the series by the end of 2025. All products are 100% backward compatible with the previous generation.

Thanks to IO-Link, all sensors in the optimized third generation can be centrally parameterized; both the switching status and the signal value can be continuously monitored. Additionally, the sensors can also be used in Standard IO mode (SIO mode), just like the previous generation. The fork light barriers feature improved specifications, including a higher switching frequency and better resolution compared to the second generation.

The device is equipped with a potentiometer for sensitivity adjustment and offers IO-Link as an interface. While the second generation could only output the switching status (High/Low), IO-Link now enables reading the exact switching signal. In contrast, BGL Entry focuses on basic functions. It does not offer IO-Link or adjustment options on the device but is significantly more cost-effective.

Focus on the essentials

The BGL Entry variants use visible red transmitter light, ensuring easy alignment. They focus on essential basic functions, reliably detecting objects regardless of color or surface. Thanks to their robust IP67 zinc die-cast housing, they perform even under demanding industrial conditions.

Fork sizes of 30, 50, and 80 mm allow for versatile applications. Mechanically, the new models are fully compatible with existing variants.

The addition of the Entry series offers users the perfect balance between functionality and user-friendliness.

- Susanne Rehrl, Product Manager, Balluff

From Conveyor Belt Monitoring to Quality Assurance

With the new BGL generation, Balluff targets customers in mechanical engineering, the automotive industry, logistics and warehousing, the pharmaceutical and medical industries, as well as the food and beverage sector. The compact sensors monitor and control conveyor belts, ensuring smooth flow and congestion control.

In assembly lines, fork light barriers detect whether all necessary parts for final assembly are present. If not, the line automatically stops, reducing waste. In CNC machining centers, BGL sensors ensure that workpieces are correctly positioned before processing begins.

In quality assurance, they verify that all components are properly assembled. If deviations occur, production can be stopped, or defective products can be sorted out.