Ambient IoT vs. RFID: Rethinking Visibility in the Supply Chain

In today’s supply chain landscape, visibility alone is no longer enough. Businesses are demanding more than just knowing where items are — they want to understand how those items are doing, what conditions they’re experiencing, and whether they’re ready for the next phase of movement. That’s the premise behind Wiliot’s latest article, “Rethinking Visibility for Smarter Supply Chains: RFID or Ambient IoT”, authored by Amir Khoshniyati.

For over two decades, RFID has delivered reliable, fast, and affordable solutions for inventory tracking. It’s become a standard for high-volume, structured environments like retail stockrooms and warehouse checkpoints. RFID delivers moment-in-time visibility — efficient and scalable, but ultimately limited to reader-based interactions.

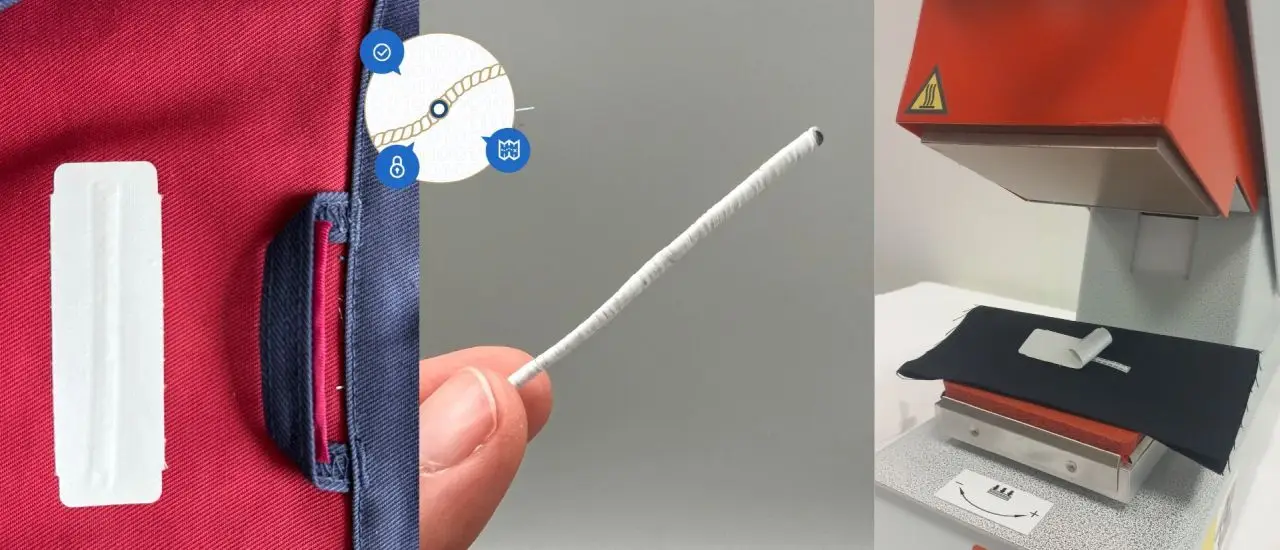

Enter Ambient IoT, a new class of sensing technology that redefines what’s possible at the item level. Wiliot’s battery-free IoT Pixels go beyond tracking. They provide real-time, ambient intelligence — gathering continuous data on location, temperature, humidity, motion, and light. These tags turn everyday objects into intelligent, communicating entities, forming a kind of nervous system for the supply chain.

The article outlines three essential comparisons:

Inventory Intelligence: RFID is fast, but Wiliot adds depth. While RFID excels at speed, Wiliot offers ongoing visibility without scanning — ideal for sensitive goods like pharmaceuticals or perishables.

Condition Monitoring: This is where Ambient IoT outperforms. Wiliot’s Gen 3 tags stream real-time condition data using standard BLE infrastructure, enabling better compliance, quality assurance, and loss prevention.

Workflow Optimization: RFID thrives in fixed environments. But in dynamic operations — where assets shift, conditions change, and real-time decisions matter — Wiliot delivers adaptive automation through always-on connectivity.

While RFID tags are cheaper per unit, Wiliot delivers higher value per item. It’s not just about cost — it’s about ROI and use case relevance. When condition, motion, or freshness matters, the equation shifts in favor of Ambient IoT.

The article doesn’t frame the debate as either-or. It’s about choosing the right tool for each task. RFID remains essential for high-speed counting and linear workflows. Wiliot becomes indispensable when context, real-time sensing, and autonomous decision-making are needed.

Supply chains are evolving from being visible to being aware. And that shift will define the next generation of efficiency, sustainability, and intelligence in global operations.

Interested in making your supply chain smarter, more responsive, and truly aware?

Reach out directly to me, Amir Khoshniyati, to explore how Ambient IoT can transform your operations — from condition monitoring to real-time inventory and beyond.