Industrial Labeling

Industrial labeling is the foundational enabler of traceable, compliant, and automated manufacturing and logistics processes in Industry 4.0.

- Revised: November 03, 2025

- By: Anja Van Bocxlaer

- Read: 12 min

- Industrial labeling establishes unique, machine-readable identities that enable traceability, quality assurance and recall management.

- RFID/NFC provide contactless, bulk reading and extra data storage, while optical codes (1D/2D) remain low-cost and standardized.

- Labeling software integrates ERP/MES/WMS, manages variable data, enforces versioning and supports audit trails for compliance.

- Robust materials and appropriate marking methods (thermal transfer, DPM, on-metal tags) are essential for durability and readability.

- Future trends include sustainable materials, chipless RFID, AI-driven verification, AR-enabled content and always-connected smart labels.

What is Industrial Labeling?

Industrial labeling ensures that products, parts, and assets are uniquely identifiable, traceable, and compliant—from inbound goods through manufacturing and logistics to the end customer.

It provides key information such as product IDs, batch and serial numbers, expiration dates, and safety and compliance details. This forms the basis for inventory control, quality assurance, recall management, and anti-counterfeiting.

In regulated industries—such as pharmaceuticals, chemicals, automotive, and food & beverage—precise labeling prevents errors and ensures compliance with legal standards.

“Industrial labeling” refers to the creation and application of labels or direct markings on products, equipment, and load carriers. The goal is end-to-end identification across the entire lifecycle—from production to disposal.

This relies on robust materials and appropriate printing/marking methods that withstand chemicals, temperature extremes, and abrasion. Labels must also adhere reliably to diverse shapes, sizes, and surfaces (metal, plastic, glass, rough/curved surfaces).

With Industry 4.0, the importance continues to grow: networked printers, automated workflows, and cloud-based labeling solutions integrate with ERP/MES/WMS and provide real-time data for planning and control.

Technologically, two approaches dominate:

Radio-based identification (RFID/NFC) – read without line of sight, bulk reading, optional security features.

Optical codes (1D/2D: barcode, Data Matrix, QR) – low cost, standardized, and quick to scan.

Integrating these technologies into labeling systems enables real-time tracking and data capture—increasing transparency, reducing error rates, and supporting data-driven decisions in production and logistics. NFC plays a role in short-range applications such as maintenance, access, or tamper protection.

Industrial Labeling Systems & Labeling Software

Overview: From Data Input to Verification

Industrial labeling systems connect hardware and software into an end-to-end process: data flows from ERP, MES, or WMS into layout design, is printed or directly marked, applied, verified, and fed back in real time. The goal is robust, standards-compliant labeling with high readability—regardless of cycle time, environment, or material mix.

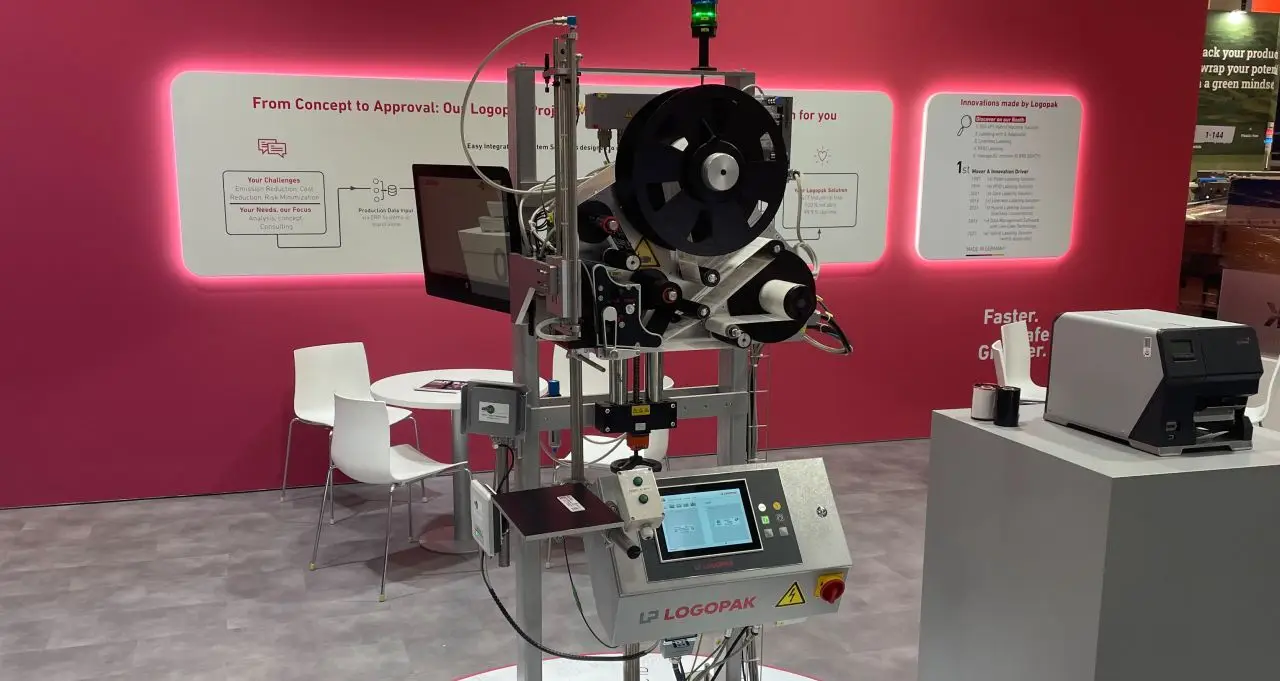

Print-and-Apply as the Line Backbone

In high-throughput lines, print-and-apply systems form the backbone. They print codes, text, and pictograms and apply the label directly to products, containers, or pallets—process-reliable at high speeds and across varying form factors.

Tamp-Blow: Precise, Contactless Application

For delicate, uneven, or moving products, the tamp-blow method is ideal: the label is held on a pad by vacuum, the applicator moves close to the surface, and a short burst of air applies the label without contact and with precision. If a defined pressing force is required, wipe or wrap methods are preferable.

Direct Part Marking (DPM)

When labels reach their limits or permanent, tamper-resistant marking is required, DPM marks the part directly—using laser, dot-peen, or industrial inkjet. This is proven in automotive, medical technology, electronics, and aerospace.

Thermal Transfer for Robust Labels

Thermal transfer delivers high contrast and resistance to chemicals, temperature, and abrasion. The process is suitable for product, safety, and logistics labels in both inline and stand-alone operations.

RFID & NFC: More Data, Less Line of Sight

RFID systems print and encode transponders in one step, enabling later reading without line of sight, bulk reading, and additional data storage for traceability and inventory management. NFC closes the short-range gap—for example, for maintenance records, access control, or product authentication via smartphone.

Additional Application Variants

Alongside inline solutions, automatic applicators place preprinted labels, while mobile handheld systems are used for on-site labeling in warehouses, maintenance, or construction. Shrink systems provide formfitting, durable identification for cables and wires.

Labeling Software: Design, Data, Control

Software is the control center, creating layouts with 1D/2D codes, text, pictograms, and graphics. Variable data such as batch and serial numbers, expiration dates, URLs, or EPCs are sourced from ERP/MES/WMS and distributed centrally—on-premises or cloud-based—to the lines. Roles, permissions, approvals, versioning, and audit trails ensure revision security; serialization and aggregation link units into cases and pallets. APIs/connectors integrate printers, scanners, and cameras as well as enterprise systems.

Compliance & Standards

Industry standards such as GS1 Digital Link, GHS, UDI, FDA 21 CFR Part 11/GMP Annex 11, EU-FIC, or ATA SPEC 2000 define content, processes, and proofs. For RFID, ISO/IEC, GS1, and EPCglobal specifications ensure interoperability and unique coding.

Machine Vision & Verification

Camera-based systems check content, position, and contrast, verify codes including grading, and control text via OCR/OCV. Deviations are reported in real time and faulty items are rejected—stabilizing first-pass yield and reducing rework.

Market & Development

The market is growing steadily—driven by compliance and anti-counterfeiting requirements, ongoing industrialization, and technological progress. The manufacturing sector and automotive, in particular, are among the largest adopters of integrated labeling solutions.

Successful Examples of IoT-Based Industrial Labeling

RFID is driving industrial labeling and identification across industries—from manufacturing and automotive to media and rental logistics. The following real-world examples show how end-to-end processes—spanning printing/encoding, application, data capture, and IT integration—boost efficiency, traceability, and process reliability.

Window Labeling at Toro Aluminium

Since 2023, the Canadian manufacturer has been labeling prefabricated aluminum components with UHF RFID. RFID printers integrated into CNC machines encode labels with production data (e.g., dimensions) and link them to the ERP system. Ceiling antennas (FEIG Electronic) on the assembly lines and gate/zone antennas (Times-7) capture the parts in real time—from cutting to goods issue.

Result: Automated scans replace manual barcodes, significantly increasing throughput and data quality.

“The pilot project made the potential very clear: automatic RFID scans instead of manual barcode scans.”

Khaled Elshimy - CEO, RFID Canada

Media/Rental: Asset ID at Rentex

The U.S. film equipment supplier has equipped over 200,000 rental items with passive UHF tags. Staff use mobile RFID readers with ranges of up to ~10 m and a “Geiger counter” function—a proximity mode in which the device signals the direction/distance to the target tag via increasing beeps or a bar display—for precise item location.

Result: Bulk inventory in seconds, ~99% time savings in the identification process, and significantly fewer picking errors.

“In aisles with tens of thousands of cables, the Geiger counter function quickly leads you to the desired item.”

Richard Aufreiter - VP Product Marketing, HID

Interview Spotlight: RFID as the Key to Production (Logopak)

Essence. Without unambiguous identification—barcode or RFID—automation, traceability, and process reliability are not feasible today. Logopak has been a pioneer since the early print-and-apply days; with RAIN RFID (from ~2004), broad industrial deployments followed.

Deployment. Systems operate primarily at the end of the line and in logistics (food & beverage, e-commerce, pharma, consumer goods)—modularly integrable from pallet labeling to side-mounted units on production lines.

Function. From data intake (ERP/MES) through variable printing and RFID encoding to precise application—including error checking and real-time diagnostics—delivered from a single source, low-maintenance, and highly available.

Software. PID 3SIXTY consolidates layouts, data, and jobs and monitors equipment in real time; the platform connects seamlessly to ERP/MES and supports RFID data flows.

“At the point where products leave the line, labeling and application must not fail: availability at the end of the line secures throughput, traceability, and on-time shipping.”

Steffan Gold, Managing Director at Logopak

Article Spotlight: Chipless RFID for Smart Packaging

Core idea. Chipless RFID (RF barcode) uses printed, conductive resonator structures instead of chips. Scanning creates a spectral fingerprint—contactless, no line of sight, no battery, and recyclable.

How it works & readers. Printed antennas (e.g., silver/carbon inks) generate resonances (typically 1–10 GHz, sometimes UHF). Reading is done via spectral analysis (VNA or SDR), not with conventional UHF readers. Range: near-field (mm to ~15 cm), already practical for packaging lines and sorting.

Advantages. Hidden, parallel reading of multiple objects; robust under dirt/moisture; hard to counterfeit (physical backscatter profile). Sustainability: fully printable on paper/films/textiles.

Bottom line. A major opportunity for smart packaging and sustainable, mass-market IoT labeling—complementing RFID and QR once readers and standards have matured.

The Future of Industrial Labeling and Identification Technologies

1) Sustainability Becomes the Standard

Labeling is increasingly designed for circularity: bio-based or recyclable label materials, solvent-free inks, recycling-friendly adhesives, and layouts that support sorting and recovery processes. Companies anchor eco-design criteria in specifications and audits—driven by regulation and customer expectations.

2) Smart Labels: From “scan required” to “always connected”

Smart labels permanently link objects to IT processes. Printable 5G/cellular labels transmit status and location data without manual scanning—ideal for shipment tracking, cold chains, and returns. In parallel, RFID/NFC variants with sensors (temperature, humidity, shock) capture conditions directly on the object.

3) AR-Enabled Labeling

AR labels bring operation, service, and compliance to the device: open the camera, scan the label, and retrieve contextual content—from 3D spare parts to step-by-step maintenance. Brands and industries (incl. gaming/consumer) show the way; in manufacturing, AR becomes digital work instructions tied to machines and materials.

4) Digital Links & Interoperability

GS1 Digital Link turns codes into web entry points: the same code serves logistics, quality, consumer info, and authenticity. Combined with UDI, GHS, EU-FIC, and EPC/ISO, this creates end-to-end data chains—from serial numbers through aggregation to traceability. The result is transparency, anti-counterfeiting, and fewer media breaks.

5) Chipless, Printed, Mass-Market Ready

Chipless RFID / RF barcodes use printed resonator structures instead of ICs. They are recyclable, cost-effective, and readable without visibility—ideal for smart packaging and high volumes. Broad adoption requires production-grade readers and standards for tag designs/frequencies.

6) AI & Edge in Printing, Application, and Verification

AI-enabled vision checks codes, text (OCR/OCV), and position in real time, learns anomalies, and reduces rework. Edge analytics on printers/applicators/readers evaluate quality (e.g., grading), dynamically tune parameters (print density, applicator force), and send predictive-maintenance signals to MES.

7) Security & Compliance by Design

With greater connectivity come higher data-security demands: signed data content, tamper-resistant serials, access and key management for RFID/NFC, and audit trails in labeling software. Privacy by default becomes part of specifications—especially in direct-to-consumer scenarios.

Bottom line: Labeling is becoming intelligent, connected, and sustainable. Organizations that align standards, data models, and smart labeling systems today lay the groundwork for seamless, scalable Industry-4.0 processes—from the shop floor to the end customer.

Benefits of Industrial Labeling and Identification

Industrial labeling creates real-time transparency: inventories, locations, and movements are continuously captured. IoT-enabled labels and tags provide minute-by-minute information on the status and condition of products and assets. This reduces overstock, prevents stockouts, and improves planning—measurably lowering inventory and process costs.

For traceability, labeling is the central data source. Serial and batch information accompanies the product throughout the supply chain and enables quality assurance, recall management, and authentication. At the same time, labels carry safety information (hazard warnings, handling, emergency measures), contributing to occupational safety and compliance.

Embedded sensor technology (e.g., temperature, humidity, shock) elevates labeling further: conditions are monitored continuously, enabling predictive maintenance and early detection of process deviations.

Finally, robust labeling helps organizations comply with rules and standards. Whether automotive, pharma, food, or chemicals: clearly defined content, serialization, and documentation fulfill legal requirements—reducing fines, complaints, and liability risks.

Wireless IoT—at a glance: greater visibility in material flows, anti-counterfeiting via unique identities, optimized inventory, real-time tracking without line of sight, and enhanced safety through verified, available information at the object.

Challenges & Solutions

Regulatory requirements and industry standards evolve continuously. Companies should therefore use rule-based labeling software with versioning and audit trails, and embed standards updates in a formal change-management process.

Errors in application or unsuitable material choices jeopardize readability and processes. Countermeasures include material/adhesion tests on original surfaces, clearly defined print/applicator parameters, and inline verification (camera, code grading) immediately after application.

International supply chains require multilingual and country-specific content. This is addressed with a central data model, localized layouts, rule-based mandatory fields, and structured translation/approval workflows in the labeling software.

Challenging environments—metal, water, or abrasion—impair readability and range. Here, on-metal tags, spacers, or tuned antennas/readers help; alternatively, DPM/Data Matrix can be used. For printed labels, choose suitable substrates and protective laminates.

The economic benefit is not always immediately visible. Organizations should therefore run pilots with clear KPIs (read rate, cycle time, error rate, inventory time), perform TCO/ROI comparisons among barcode, RFID, and DPM, and roll out stepwise based on measurable impact.

Outlook – Next-Level Industrial Labeling and Identification

AI in printing, application, and software.

AI/edge algorithms optimize labeling in real time: they detect anomalies in codes and text (OCR/OCV), auto-tune print parameters (e.g., density, speed), adapt applicator motion to part geometry, and predict maintenance needs—raising first-pass yield, reducing downtime, and stabilizing quality.

AR labels: instruction, service, audit.

AR triggers on labels or direct markings open contextual content via smartphone/tablet: step-by-step maintenance, 3D parts, safety/compliance notes, and training at the object. In production and service, AR replaces static documents with current, versioned work instructions—including photo/video proof for audits.

Personalization & variable data.

With variable data printing, IoT integration, and analytics, tailored labels emerge per product, country, batch, or customer: serialization, aggregation, language/legal-compliant content, dynamic QR/GS1 links, and condition-dependent notices (e.g., temperature, shelf life). This boosts traceability, compliance, and user acceptance—up to personalized service or returns flows.

Next-level labeling blends AI-driven processes, AR-driven content, and personalized, compliant labels—for measurably higher quality, speed, and transparency across the supply chain.

Digital Product Passport (DPP)

The Digital Product Passport is a standardized data set that provides transparent information on materials, origin, use, service, and recycling across the entire product lifecycle—measurably supporting circularity and sustainability goals.

In industrial labeling, QR/Data Matrix (GS1 Digital Link) and RFID/NFC serve as physical entry points to the DPP: they connect the visible or contactlessly readable identifier with serialized product data and events. This makes traceability, compliance, and efficient processes available directly at the object—from manufacturing and logistics to end-of-life.