Automating Mining Stockyard Machines with Robust Sensor Technology from Pepperl+Fuchs

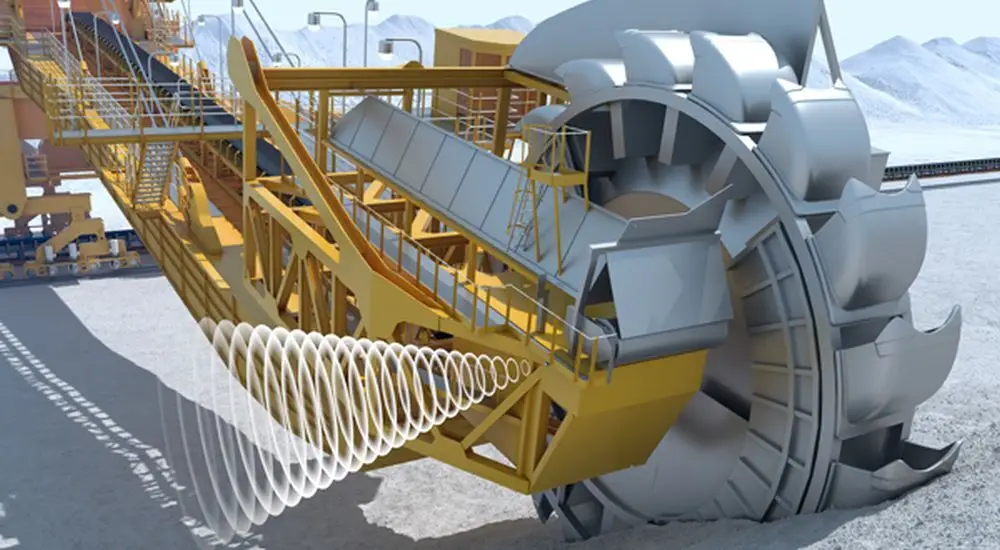

Automated stockyard stackers and reclaimers are key to reliable inbound receipt and outbound delivery of mined material. To optimize stockpile management even further, mining operators are integrating modern sensor technology that enables precise positioning, collision protection, and condition monitoring even in dusty, dirty, and vibration-heavy environments.

In a new application overview, Pepperl+Fuchs highlights how rugged sensing solutions support the complete and reliable automation of stockyard machine operations, from travel positioning to boom monitoring and safe movement control.

Exact machine positioning with RFID and rotary encoders

Accurate positioning is the basis for smooth stacking and reclaiming. A typical setup combines fixed RFID tags along the travel path with an RFID read/write device mounted on the moving machine, plus a multiturn absolute rotary encoder for continuous position feedback.

RFID tags are installed at defined intervals (typically every 10 to 15 meters). When the read/write device detects a tag, the stored position information is compared with the rotary encoder value to confirm the machine’s exact location in the stockyard. Rugged RFID components with IP67 protection support reliable reading and high repeat accuracy in harsh mining conditions.

UT-F190-B40 UHF RFID Reader

The UT-F190-B40 is a rugged, connected UHF RFID reader designed for reliable medium-range industrial identification and seamless integration with modern automation systems.

Pepperl+Fuchs RFIDControl software additionally supports commissioning and device access, with multiple options for PLC integration.

Collision protection with ultrasonic sensors

Uneven material stacks and limited visibility make boom collisions a major risk in mining stockyards. Ultrasonic sensors continuously monitor the machine’s travel path and detect material in the danger zone. If a collision is imminent, the system can trigger immediate corrective actions to prevent damage and improve safety on site.

Monitoring boom inclination and movement with inclination sensors

Boom angle directly affects efficiency and safety. Inclination sensors provide real-time data on boom position, helping operators optimize material placement and proactively address issues during movement. This supports more stable operation and more consistent handling performance.

“In mining, some machines simply can’t stop. With the right sensors, operators gain greater precision, safety, and reliability. The Pepperl+Fuchs Group shows how this works in practice.” - Daniela Bomfim Alves, Marketing Coordinator, Pepperl+Fuchs Brasil

Monitoring cable reel and wheel assembly with IO-Link sensors and encoders

Condition monitoring helps reduce downtime and supports predictive maintenance. Pepperl+Fuchs solutions for stockyard reclaimers include:

IO-Link vibration sensors to detect changes in vibration and acceleration and identify potential issues such as imbalance, misalignment, or excessive wear

IO-Link multiturn absolute rotary encoders to measure wheel rotation, speed, and direction for navigation and control feedback

Inclination sensors to ensure assemblies remain within specified angles for stability and hazard prevention

Defining operational boundaries and detecting moving parts with inductive sensors

Robust inductive sensors with IP67 protection serve as reliable limit switches to define operating boundaries and prevent overextension or unintended movement. They also detect motion of critical machine components to ensure operation within predefined parameters, improving safety and supporting equipment longevity.

Pepperl+Fuchs on the road to automation in mining

By integrating RFID, ultrasonic, inclination, IO-Link vibration, rotary encoder, and inductive sensing solutions, mining operators can automate stockyard machine operations more reliably. The result is improved availability, safer processes, and more efficient material handling, contributing to a more competitive and sustainable mining operation.

Want to automate or retrofit your stockyard stackers and reclaimers with robust sensing technology? Talk to Pepperl+Fuchs about the right solution for exact positioning, collision protection, and condition monitoring in harsh mining environments. Get in touch!