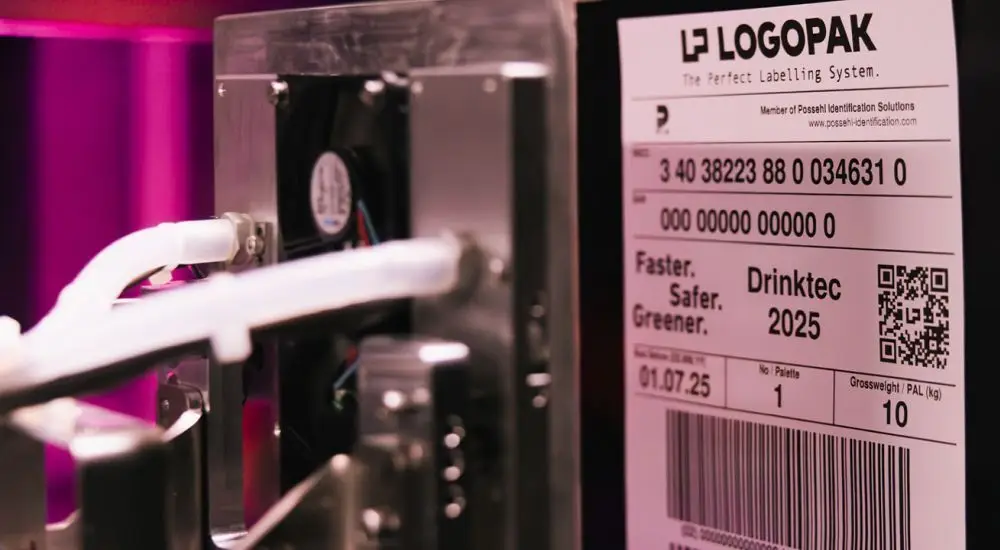

Logopak presents sustainable labeling solutions at drinktec 2025

Logopak Systeme at drinktec 2025

Logopak Systems will be presenting new labeling solutions for the beverage and liquid food industry at drinktec 2025 in Munich (September 15–19, Hall C2, Booth 448).

The focus will be on technologies that reduce energy consumption and waste, digitize processes, and help companies implement the requirements of the future EU Packaging and Packaging Waste Regulation (PPWR).

With over 1,000 exhibitors from 55 countries, the drinktec trade fair sees itself as a global economic summit and a technological driving force for the beverage and liquid food industry – and thus as a global platform for innovation, networking, and the future of the industry.

"With its portfolio of high-performance, sustainable, and digitized labeling solutions, Logopak makes important contributions to key trade fair topics such as circularity and resource management or Data2Value – in other words, to efficient and resource-saving circular economy in beverage production and data-based value creation," explains Steffan Gold, Managing Director at Logopak Systeme. "That's why we're in exactly the right place here with our labeling solutions for breweries, mineral water producers, beverage and liquid food manufacturers."

Sustainable pallet labeling: 850 eP3 Hybrid

One highlight is the 850 eP3 Hybrid pallet labeling system, which for the first time operates completely without compressed air. This enables companies to significantly reduce their energy consumption and CO2 footprint – a decisive advantage against the backdrop of increasing regulatory requirements for resource efficiency and climate protection.

The system processes either direct thermal or linerless labels without backing material, saving around one ton of CO2 and considerable amounts of waste per 400,000 labeled pallets (in two-shift operation).

Compact entry-level model: Logomatic 715 PF

The Logomatic 715 PF is aimed at companies looking for a space-saving solution for 2-sided labeling. With up to 120 pallets per hour, it is particularly designed for standard applications. Functions such as a real-time clock, compressed air monitoring, and an integrated article database support efficient processes. Thanks to its reduced footprint and optimized energy consumption, the system fits well into sustainability strategies.

Residue-free labeling with string: 850 PSC

Logopak introduces the 850 PSC string labeling system for reusable beverage crates. It attaches labels to a reusable string made of recycled fibers. This completely eliminates plastic bands and adhesive residues. This facilitates the return of crates, saves resources, and supports companies in implementing circular economy concepts in accordance with PPWR requirements.

Maximum availability through tandem labeling

The new Logomatic tandem system in the 500 series enables uninterrupted labeling even during roll changes or maintenance. Two units work alternately or in parallel. For production lines with high throughput, this means maximum availability with optimized material usage.

PID 3SIXTY software platform: data management and traceability

In addition to hardware, Logopak presents the PID 3SIXTY software with manage.ID and monitor.ID. It supports automated data transfer from ERP/MES systems, standardized print layouts, and live monitoring of machine statuses. This allows batches to be traced seamlessly, downtime to be reduced, and legal documentation requirements to be met efficiently.