IoT in Automotive Industry: Tackling the Challenges of Digital Transformation

Integrating wireless IoT technologies across manufacturing, supply chains, vehicles, and infrastructure is the strategic foundation for automotive digital transformation and the next era of mobility.

- Revised: October 07, 2025

- By: Anja Van Bocxlaer

- Read: 6 min

- Wireless IoT technologies such as RFID, 5G and UWB enable real-time transparency and precise indoor localization in production.

- Condition-based and predictive maintenance driven by sensors and analytics reduce downtime and extend asset lifetimes.

- RFID, digital twins and blockchain-capable platforms strengthen lifecycle traceability and support regulatory initiatives like Digital Product Passports.

- Standards like OPC UA and unified IoT data platforms are essential for interoperability, quality assurance and scalable Industry 4.0 deployments.

The IoT in automotive industry is no longer optional—it is the strategic response to the sector’s most pressing challenges. From production efficiency and supply chain resilience to sustainability and customer expectations, the automotive industry faces structural changes that require new technological foundations.

Wireless IoT technologies like RFID, 5G, OPC UA, Bluetooth LE, UWB, IoT sensors, and cloud platforms directly address these challenges. By enabling transparency, automation, and predictive intelligence, they form the backbone of automotive digitalization.

The following sections outline the main challenges of the automotive industry and show how IoT solutions and real-world projects are helping to overcome them.

Challenge 1: Reducing Downtime and Optimizing Maintenance

To-Do: Automotive factories run on tight schedules. Downtime due to machine failures or inefficient maintenance quickly translates into high costs. Manufacturers need systems that detect problems early and allow condition-based servicing instead of fixed schedules.

How IoT Helps:

RFID in automotive manufacturing assigns components a digital identity.

IoT sensors measure usage data (vibration, temperature, rotation speed).

Predictive analytics trigger maintenance only when necessary.

Case Study – Audi (RFID-Based Maintenance):

At Audi’s paint shop in Ingolstadt, Dürr and Kathrein Solutions introduced RFID-tagged components that store operational data. Instead of replacing atomizers and valves at fixed intervals, maintenance is performed when the data indicates wear. This condition-based maintenance reduced costs, extended lifetimes, and increased availability.

Challenge 2: Real-Time Transparency in Production

To-Do: Global automotive supply chains and complex assembly lines require real-time tracking of tools, vehicles, and components. Without precise localization and visibility, bottlenecks and inefficiencies occur.

How IoT Helps:

5G in automotive industry offers ultra-low latency data transmission.

UWB and RFID provide accurate indoor localization.

Hybrid IoT platforms integrate multiple tracking technologies.

Case Study – BMW (5G Localization):

BMW’s IPS-i platform integrates 5G, RFID, and UWB to localize carriers, tools, and vehicles inside the factory with sub-meter precision. This enables production managers to detect bottlenecks and optimize flows in real time.

Case Study – IVECO (RFID Paint Shop):

IVECO uses UHF RFID antennas to automatically identify bus frames during the paint process. Manual barcode scans were eliminated, errors reduced, and production flow improved.

Challenge 3: Supply Chain Resilience and Lifecycle Tracking

To-Do: Automakers depend on hundreds of suppliers. Supply disruptions cause expensive downtime, while regulatory pressure demands transparency and traceability across the lifecycle.

How IoT Helps:

RFID and IoT sensors track parts and materials.

Digital twins ensure real-time visibility of assets.

Blockchain and cloud platforms secure data exchange across suppliers.

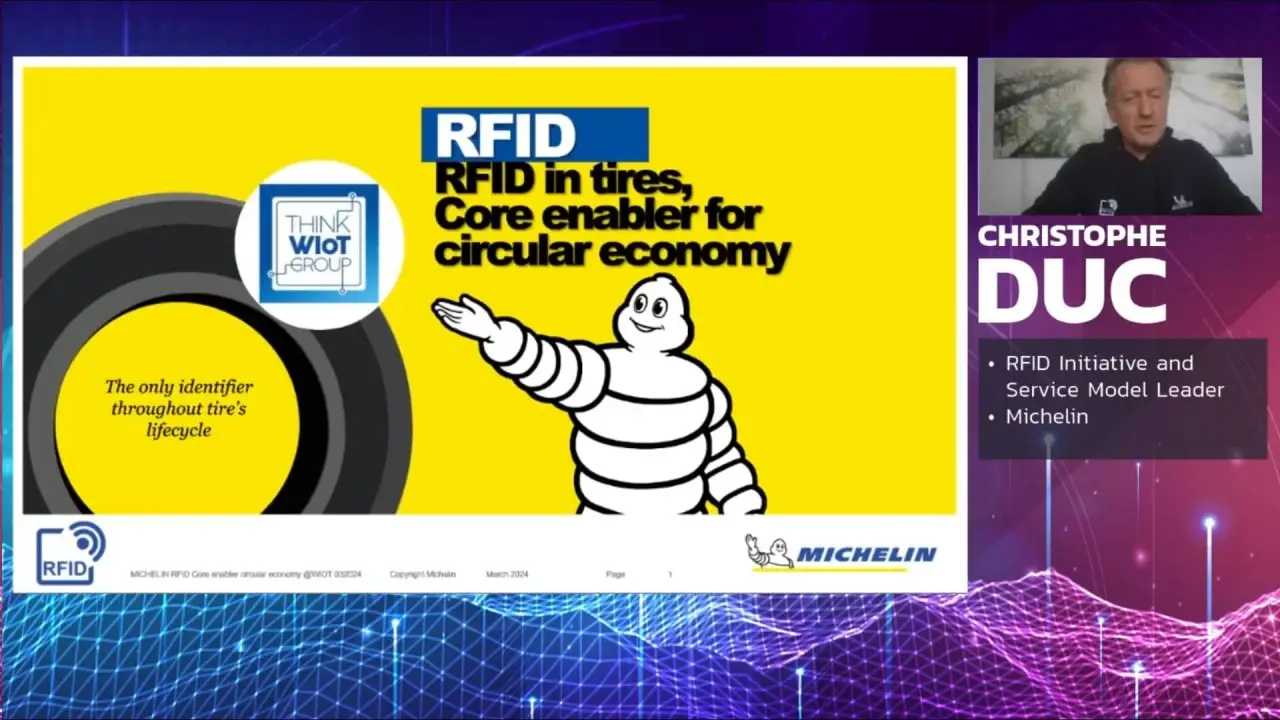

Case Study – Michelin (RFID-Connected Tires):

Michelin equips all truck and passenger tires with embedded RFID chips, enabling traceability from production to recycling. Each tire is linked to the vehicle VIN and coded with GS1 SGTIN-96 standards, supporting logistics, quality, and the future Digital Product Passport (DPP) in Europe.

Challenge 4: Quality Assurance and Standardization

To-Do: Automotive production involves thousands of machines and systems worldwide. To achieve Industry 4.0 goals, manufacturers need standardized communication, consistent quality control, and interoperability between plants.

How IoT Helps:

OPC UA in automotive industry provides a universal standard for machine-to-machine communication.

RFID tags and labeling solutions ensure parts are uniquely identified and tracked.

IoT data platforms unify analysis and quality reporting.

Case Study – Renault (OPC UA Digital Transformation):

Renault connected over 12,500 devices across 29 production sites with OPC UA and MQTT, enabling uniform data flows from sensors to cloud systems. This large-scale integration harmonized communication and created the foundation for scalable Industry 4.0 projects.

Case Study – Precision Labeling:

Industrial labeling solutions ensure that highly automated production lines maintain accuracy at high speeds. In combination with RFID and OPC UA, they guarantee error-free identification and traceability across production environments.

Challenge 5: Component-Level Intelligence

To-Do: Automakers need smarter components that carry their own data, enabling predictive maintenance, compliance, and lifecycle management.

How IoT Helps:

High-memory RFID tags embed part-specific histories.

Digital twins mirror every component in virtual systems.

Edge computing processes data close to the source.

Case Study – NXP UCODE 9xm:

NXP’s UCODE 9xm RFID tags are robust, high-capacity identifiers designed for automotive components. They allow each part to store its digital record, enabling predictive maintenance and quality assurance directly on the component level.

Challenge 6: Secure Vehicle Identification & Infrastructure Integration

To-Do: As vehicles become part of smart infrastructure, secure identification is critical—for tolls, parking, access control, regulation, and anti-fraud systems. Traditional plate recognition or barcode methods are insufficient.

How IoT Helps:

Embedding RFID in license plates or windshield tags enables secure, contactless vehicle identification.

Middleware and secure protocols ensure authentication, data encryption, and privacy.

Roadside RFID readers/gates integrate with traffic systems and urban infrastructure.

Case Study — Tönnjes IDePLATE (RFID License Plates):

Tönnjes offers RFID-enabled license plates (IDePLATE) and windshield tags (IDeSTIX) coupled with backend authentication (IDeTRUST). Vehicles can be detected contactlessly at 10–15 m range. The RFID chip holds limited, non-sensitive data (e.g. plate color, type) while personal identity remains secured in backend systems through cryptographic methods. This enables mobility infrastructure to verify vehicles reliably while preserving privacy and security.

This case shows how IoT in automotive industry extends beyond factories into mobility systems and smart infrastructure, ensuring that vehicles can operate securely and interoperably in connected environments.

Challenge 7: Integrating Electromobility & Charging Infrastructure

To-Do: With the shift to electric vehicles (EVs), automakers and infrastructure providers must manage charging station access, user authorization, billing, and usage tracking. The challenge is to provide a secure, seamless user experience while supporting large-scale charging networks.

How IoT Helps:

RFID-based authentication enables secure and intuitive driver / vehicle identification at chargers.

IoT sensors and back-end connectivity collect usage data (charging duration, energy consumed).

Integration with cloud billing systems, fleet management, and grid services supports scalable operations.

Case Study — RFID Enhances the Electromobility Ecosystem:

RFID plays a central role in EV charging infrastructures. By embedding RFID in vehicles or issuing RFID cards/fobs to drivers, charging stations can authenticate users, start/stop charging sessions, and bill usage accurately. The system ensures only authorized users gain access, tracks station usage, collects real-time usage data, and can integrate with vehicle electronics (e.g. via CANbus) for personalized services.

This project demonstrates how IoT in automotive industry is vital not only for production but also for mobility infrastructure, enabling EV ecosystems to scale securely and efficiently.

Conclusion: IoT in Automotive Industry as the Strategic Solution

The IoT in automotive industry is not a collection of disconnected technologies—it’s a pragmatic toolkit to address the industry’s most critical challenges.

From predictive maintenance (Audi), real-time tracking (BMW, IVECO), lifecycle traceability (Michelin), standardization (Renault, labeling), intelligent components (NXP), secure vehicle identity (Tönnjes), to EV charging interoperability (RFID in electromobility)—these case studies show how wireless IoT technologies deliver measurable impact.

As the mobility landscape evolves, success in the automotive industry will depend on integrating these IoT systems across production, supply chains, vehicles, and connected infrastructure. The companies that create and operate these ecosystems will lead the next era.