- High-quality ferrite cores enable stable RFID/NFC performance even when transponders are embedded in metal.

- Neosid tailors resonant circuits to specific metals to maximize read range and signal reliability.

- A patented mechanical locking method provides permanent anchorage inside tiny drill holes for robust integration.

- Devices are readable by low-energy readers, including smartphones at 13.56 MHz NFC.

- In-house production and material expertise allow rapid customization for diverse industries and Industry 4.0 use cases.

Areas of application: Medical technology, tunnel construction, beverage industry, heavy industry, Industry 4.0

RFID in metal with miniature transponders from Neosid

Neosid's core competence lies in the development of miniature RFID transponders that function reliably even in extremely demanding metallic environments.

Whether in stainless steel, aluminum, or titanium, ferrite-based technology minimizes signal loss, enabling stable communication. This allows applications such as tool identification, track & trace, predictive maintenance, and digital identification to be implemented in Industry 4.0.

Matthias Höß, Head of Development and Project Management at Neosid, explains the challenges for miniaturized transponders in metallic environments in an interview.

Ferrite as the key to RFID in metal

Why is the ferrite core the key to RFID in metal, especially for NFC readability at 13.56 MHz?

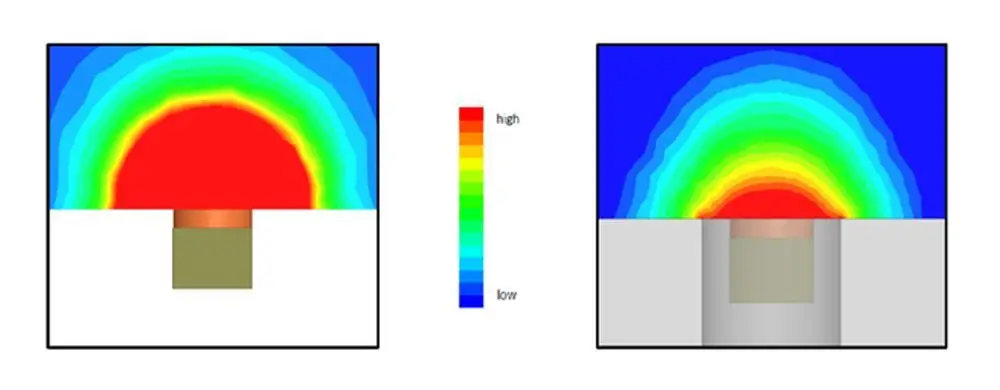

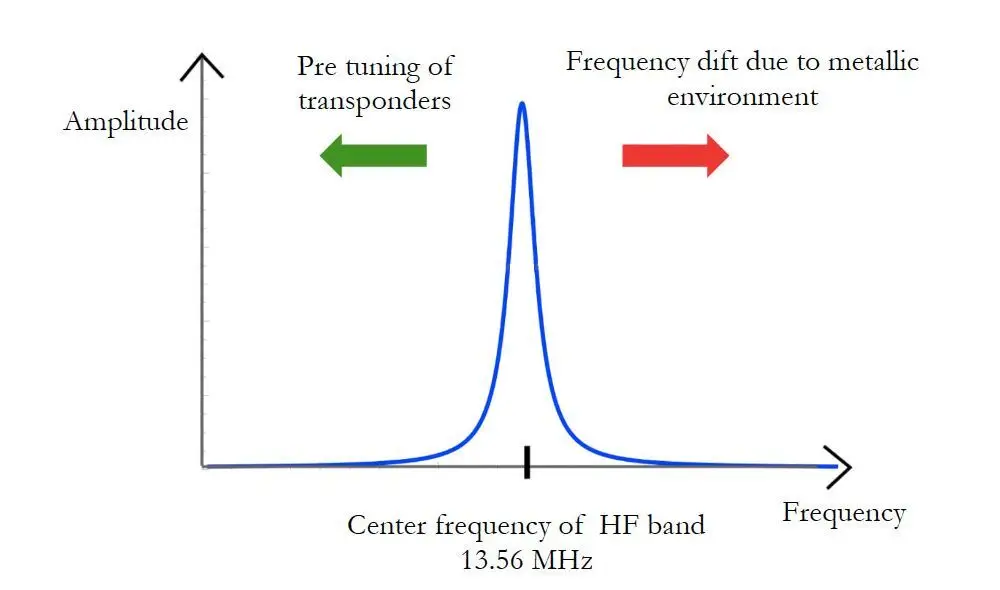

Matthias Höß: Metal can greatly attenuate or distort RFID signals. Ferrite, on the other hand, acts as a targeted signal amplifier and ensures that RFID works stably in metal even in the harshest industrial environments. Ferrite is particularly crucial in NFC technology at a frequency of 13.56 MHz to ensure stable communication between the transponder and the reader.

This means that miniaturized NFC transponders can even be reliably read by mobile devices such as smartphones, even though these have limited energy sources.

Is metal still a showstopper for miniature RFID transponders in industrial environments (Industry 4.0, Smart Factory)?

Matthias Höß: Not anymore. What was long considered an insurmountable obstacle for RFID can now be overcome. Metallic devices and objects that are exposed to harsh conditions, high temperatures, vibrations, or strong impacts can now be identified with particular reliability.

The miniature transponders are anchored directly in the object: they are inserted into tiny drill holes and locked in place with a patented solution. This creates a permanent and stable anchorage in the object.

This makes objects smart that previously could not be integrated into IoT or RFID systems. This opens up completely new possibilities – from Industry 4.0 and smart factories to predictive maintenance and the complete digitalization of the entire value chain. It also means end-to-end asset tracking and digital traceability.

The first transponders were used in the dental sector, for example on surgical instruments, starting in 2012. Today, the field of application is much broader: all industries that want to track, mark, and identify metal objects benefit from miniaturized transponders for use in metal.

Why is the combination of miniaturized transponders with metal so challenging?

Matthias Höß: Metal strongly influences the resonant circuit of a transponder and can significantly impair signal quality. However, not all metals are the same. Whether the transponder is integrated into aluminum, stainless steel, or brass makes a considerable difference to the electromagnetic properties. This is precisely where our technological specialization lies.

Our core competence lies in developing miniature transponders that function reliably even in extremely challenging metallic environments. Each transponder is precisely tailored to the respective material to ensure maximum read ranges and maximum reliability.

What ferrite-based solution does Neosid use to enable RFID in metal with stable read ranges?

Matthias Höß: Our solution consists of high-quality ferrite cores that we develop and manufacture ourselves. This is where our specialization comes into play: each transponder is precisely tailored to the respective material in order to achieve maximum read ranges and highest performance. Our goal is to always have the transponder operating in the optimal frequency range.

For NFC, for example, this is 13.56 MHz. To achieve this, we use high-quality ferrite cores. Thanks to our ferrite expertise, the transponders deliver stable signals even in complex metallic environments and can be read reliably—even with mobile devices that have limited power.

Where are your miniature RFID transponders used, from medical technology to heavy industry?

Matthias Höß: Wherever reliable identification in a metallic environment has been difficult up to now. In medical technology, for example, they are used to label surgical instruments and durable dental tools that must withstand high-temperature sterilization processes. In mechanical engineering and industry, they are used to identify tools, machine components, and safety-critical parts.

Our transponders are also used in tunnel construction, for example in tunnel boring machines, where extreme vibrations and harsh environments require maximum robustness. In the chemical and beverage industries, they enable the marking of metal drums and production containers to ensure complete traceability and optimize processes.

In logistics and raw materials, they enable the digital identification of metal profiles or strand materials that were previously only marked with color. Even in ports and heavy-duty applications such as cranes, hooks, and eyelets, they ensure reliable marking despite being exposed to high mechanical loads.

How flexible are you when it comes to customizing materials and mechanical integration (drill hole installation, locking)?

Matthias Höß: Good question, because many customer inquiries actually require customized solutions. For example, a customer may specify that the transponders must be integrated into brass or steel components. In such cases, we adapt the transponders precisely to this environment in order to achieve an optimal reading range—even with minimal energy input.

Our standard transponders are perfectly matched to non-metallic environments and to stainless steel, which is often used in mechanical engineering or toolmaking. If necessary, we can also develop transponders for all other metals. For example, titanium, aluminum, zinc, copper, or even cast iron.

So you can also develop completely new RFID transponders?

Matthias Höß: Yes , that is one of our great advantages. Our expertise in the areas of ferrite, chip integration, winding technology, packaging, and encapsulation comes into play here. The entire production chain is located in-house. Thanks to the short distances between development and production, we can implement customer-specific adaptations particularly quickly and efficiently.