- Chipless RFID tags combine identification and sensing by encoding information in a printed resonator's backscatter spectrum.

- Tags are printable on paper, film or biodegradable substrates using conductive inks, enabling sub-cent to low-cent production costs.

- Reader types include VNAs for development, SDRs for pilot systems, and industrial broadband readers for production lines.

- Typical practical ranges are millimetres to decimetres; interference and limited range remain practical constraints.

- Early applications include smart packaging freshness indicators, logistics bulk monitoring, pharma temperature tracking, construction strain sensing, and biodegradable soil sensors.

Smart, affordable, contactless—how far has sensor technology come without chips?

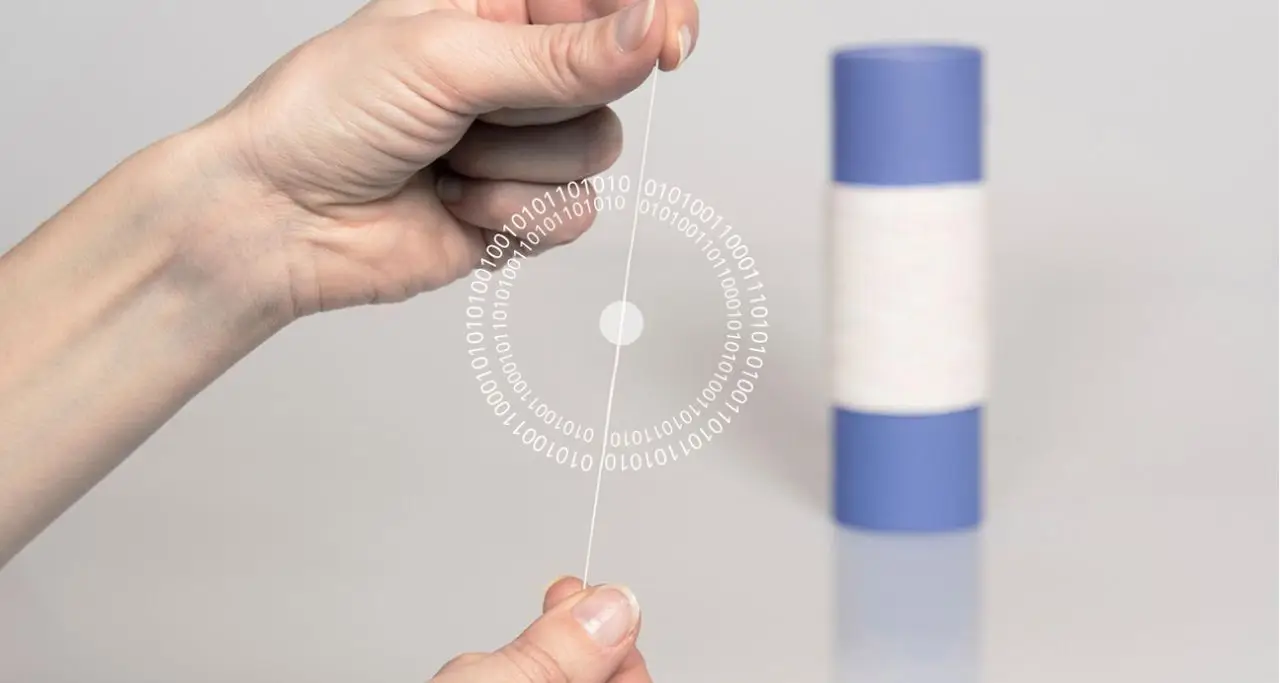

Chipless RFID sensors promise identification and measurement without microchips or batteries – printed, cost-efficient, sustainable. This article shows where the technology stands today, how printed resonator structures work, which materials and manufacturing methods are becoming established, which reader solutions are making the transition from the laboratory to the production line, and where applications such as smart packaging, logistics, and agriculture are already benefiting.

What are chipless RFID sensors?

Chip-less RFID sensors are printed, passive resonator tags without microchips or batteries. They are detected by the reader's radio signal and respond not with data packets, but with a characteristic backscatter "fingerprint" that contains both identification and measurement data.

How it works – step by step

The reader sends a radio frequency signal (usually broadband).

The printed resonator (e.g., antenna/LC resonator) reflects the signal.

Resonance points (peaks/notches) appear in the backscatter spectrum.

Environmental variables such as humidity, temperature, or strain shift/attenuate these resonances.

The evaluation calculates the ID/fingerprint and sensor value from the position and shape of the resonances.

What does a tag consist of?

Conductor structures: e.g., silver, copper, or carbon inks (printable via screen printing/flexo/inkjet).

Substrate: paper, films, or biodegradable materials (biopolymers).

Geometry: Antennas, LC resonators, metamaterial patterns – optimized for the target frequency and measured variable.

What quantities can it measure?

Humidity (the greater the electrical permeability, also known as permittivity, of the material, the lower the resonance frequency)

Temperature (changes in material coefficients shift peaks/notches/resonance frequencies, also known as spectral drift)

Strain/load (a change in geometry/impedance leads to a notch shift)

Chemical parameters/ions (coatings that react specifically to a substance change the electrical properties of the resonator. This can be seen in the spectrum of the Q factor and amplitude of the resonance).

How does this differ from classic RFID or QR codes?

Compared to UHF RFID (with chip):

Chip-less RFID is cheaper, more sustainable, and printable.

There is no standardized protocol response and the ranges are shorter (usually mm or dm instead of m).

Compared to QR codes:

No visual contact required, bulk scanning possible;

Requires radio frequency reader instead of camera.

Typical operating data (today)

Frequencies: UHF to microwave (≈ 0.8–10 GHz, depending on application)

Range: Millimeters to decimeters (line/scanner zone), sometimes more in the laboratory

Cost perspective: Sub-cent to low cent per day for roll-to-roll printing

Sustainability: No chip, no battery, recyclable/degradable depending on substrate

Core idea: The frequency fingerprint becomes the ID, the fingerprint change becomes the measurement – thus, chip-less RFID combines labeling and sensor technology in a single, extremely simple component.

Materials & manufacturing

Depending on the quantity and required resolution, chipless RFID sensors are printed on paper, film, or biopolymers using screen printing, flexo, or inkjet – and on biodegradable substrates if desired. Silver and more cost-effective alternatives such as copper or carbon are used as conductive inks; conductive polymers and graphite are also increasingly being used to enable recyclable designs.

The tags can be equipped with functionalized sensor layers that react specifically to moisture, pH/ions, temperature, or strain, thereby changing the resonance.

For large quantities, roll-to-roll production with inline drying and optional inline measurement technology (e.g., impedance or optical checks) is recommended.

The result is very inexpensive units, potentially in the sub-cent to low-cent range – without batteries, without electronic waste, and, depending on the choice of materials, recyclable or even biodegradable.

Reader technology: From the lab to the production line

Because chip-less tags do not have a microchip, they do not send a protocol response. Instead, their structure changes the transmitted radio signal in such a way that a backscatter spectrum with resonance points (peaks/notches) is created. Readers must measure and interpret this spectrum precisely.

Vector network analyzer (VNA):

In the laboratory, the VNA reader is the reference tool. It excites broadband and measures with extreme precision at which frequencies the tag absorbs or reflects energy. The result: a high-resolution fingerprint – ideal for design, calibration, and material testing.Software-defined radio (SDR):

The SDR is a programmable radio device that adjusts transmission and reception characteristics via software. This allows recognition and ML algorithms to be implemented directly: e.g., resonance search, drift compensation, multiple recognition in real time. SDRs are flexible and more cost-effective than VNAs – perfect for pilot plants and prototype readers.Broadband readers (UHF/microwave):

Compact devices are being developed for industry that, similar to an RFID reader, are specifically designed for chip-less reading: robust housing, integrated antennas, API for connection to PLC/MES, and sufficient bandwidth to reliably detect resonances. The goal: line- and gate-compatible detection without laboratory effort.

VNA for development, SDR for flexible piloting, and industrial broadband readers for series production – this is how laboratory spectroscopy becomes a line-compatible technology.

Practical values & challenges

Currently, ranges are mostly in the mm to decimeter range (depending on frequency, tag design, material). This is already suitable for practical applications such as packaging lines, goods receiving gates, or scanner zones.

Multiple tags can be detected in parallel, but without a classic anti-collision protocol: Separation is achieved via different spectral fingerprints, position/distance, time (movement/gating), or polarization.

Multipath (multiple path propagation through metal and the environment) and humidity are among the key interference factors; the latter attenuates and shifts the resonances. This can be remedied by using directional antennas, clearly defined measurement geometries, reference markers, appropriately selected frequency windows, and robust algorithms (filtering, ML classification, drift compensation).

Applications & status in practice

Smart packaging & retail – freshness/moisture indicators, authenticity verification, concealed labeling without visual contact.

Logistics & cycles – bulk recording, leakage/moisture monitoring in crates/containers.

Pharma & MedTech – Tamper protection, conclusions about temperature progression using spectral effects. Some temperature fluctuations are reversible (temperature rises → frequency drops, falls → frequency rises again). Others are cumulative: after prolonged heat exposure, a permanent shift remains.

Construction & Infrastructure – Chipless strain sensors in concrete/asphalt/fiber composites.

Agriculture & Environment – Soil moisture/ion sensors on degradable substrates for point-dense measurement networks – currently being tested in European field trials, where passive, chipless RFID sensor nodes on biodegradable substrates measure soil moisture and nutrient content. The tags decompose in an environmentally friendly manner after use; AI-supported evaluation provides recommendations for irrigation and fertilization.

Conclusion

Chipless RFID sensors combine labeling and measurement on printable, cost-efficient, sustainable structures. With maturing reader technology and ongoing field tests, the potential for smart packaging, supply chain, and Industry 4.0 is growing – right up to degradable sensor networks in the field. Those who pilot now will secure transparency, cost advantages, and new data points directly on the product.