- An integrated UHF RFID system automated issuance and returns, enabling 24/7 availability and real-time tracking.

- The rollout covers 18 dispensing locations and an automated cabinet, averaging about 6,000 garments issued daily (~150,000 monthly).

- Daily HR synchronization and APIs ensure employee profiles, sizes, and limits are current across the system.

- A reporting and analytics layer delivers KPIs and dashboards that support data-based demand planning and SLA monitoring.

- Automated processes reduced manual sorting and counting time, improved traceability, hygiene compliance, and operational transparency.

Management and distribution of 150,000 items of workwear per month

The University Medical Center Ljubljana (UKC) is transitioning from paper forms to RFID-based workwear management. The reason for this change was typical for large hospitals: lack of transparency, high manual effort, no reliable analyses, and time-consuming inventory checks.

Today, an integrated UHF RFID system ensures automated issuance and return, with 24/7 availability, reliable data, and clear processes. The next step is to expand the automated issuance systems, especially in clinical departments outside the main building and in new buildings. Looking ahead, the UKC plans to integrate artificial intelligence into its analyses.

The University Medical Center Ljubljana

With around 8,600 employees, the University Medical Center Ljubljana is one of the largest institutions in Slovenia. The University Medical Center Ljubljana is a public health institution that provides secondary and tertiary health services as well as education and research activities. Capacity: around 2,100–2,166 beds.

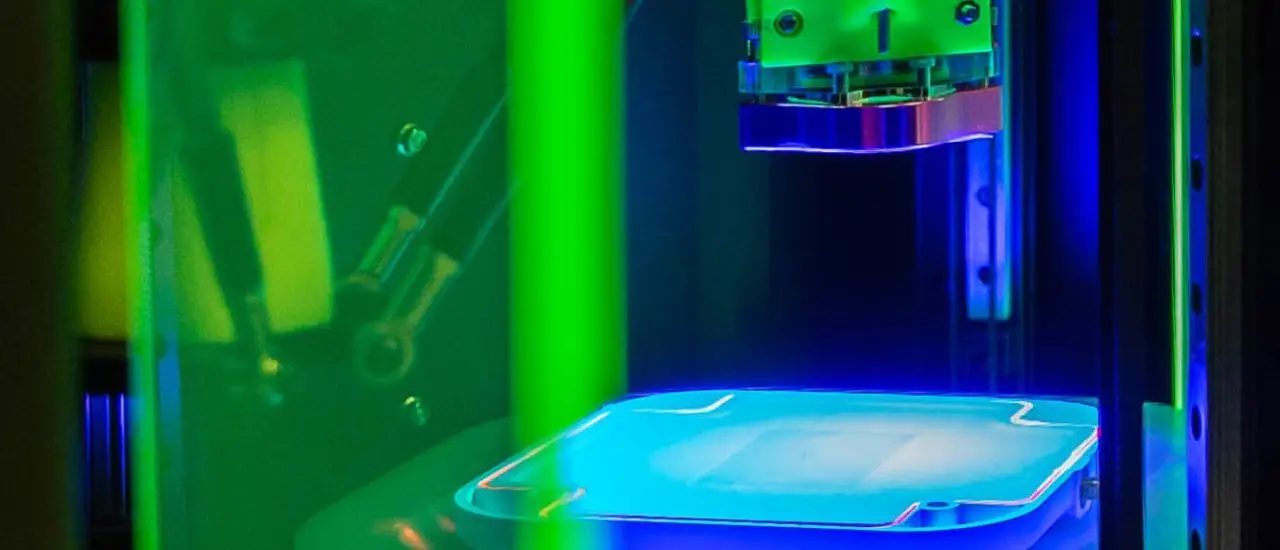

Automated dispensing cabinet in closed-loop operation

In March 2025, the automated dispensing and return device was seamlessly integrated into the existing RFID system and initially tested in regular operation. At the front, an RFID card reader for unique user identification and a touchscreen provide guided selection of items.

Employees authenticate themselves with their ID card, immediately see the items available to them, and confirm the size and item with a tap of their finger; the item is then dispensed automatically.

Returns are also fully digitized: after logging in, the return window opens, the soiled clothing is inserted, and the process is completed by closing the flap.

Inside, there is a clearly structured shelving system with 22-centimeter-wide, labeled drawers, which are filled in a standardized manner by service personnel. Each item is equipped with a sewn-in RFID tag; integrated antennas and sensors reliably detect which items have been removed or returned and record the transaction in the system without media discontinuity.

An app notification also informs when the collection trolley for used laundry is full and needs to be emptied.

Everything at a glance – around the clock

In short: the clothing is available 24/7, the status of each item can be checked in the device at any time, and automatic notifications are sent when stocks are low. User profiles are maintained directly in the application – without any detours.

At the same time, the seamless recording of all movements ensures real-time transparency across the entire textile cycle, from removal to cleaning. This provides precise evaluations and planning that is based on knowledge rather than estimates.

Technical project start

Before the project began, the issuance of work clothing was documented manually. Analyses were only possible with great effort, and inventories were inefficient. In addition, the issuing stations did not have internet connections. The first step in the project was therefore to create the infrastructure. 18 issuing stations were equipped with touchscreen computers, antennas, and RFID readers.

Why? From the outset, the solution was to focus on process speed, data quality, and transparency.

The objectives: robust data capture, stable interfaces, clear operating logic. After successful testing, which lasted three months, the rollout began step by step across all locations. Today, an average of 6,000 garments are issued daily.

"The switch to automated dispensing was initially met with reluctance – a common reaction to process changes. The decisive factors were the ease of use and the reduced waiting time. Acceptance grew rapidly as the 24/7 supply proved its worth in everyday use." – Dr. Danijela Kralj, Head of Supply Services, University Medical Center Ljubljana.

From pilot operation to closed-loop textile logistics

The introduction began with a pilot and basic operation phase, during which local dispensing processes were stabilized and the master data logic for employees, departments, sizes, and target quantities was defined. This was followed by a staggered rollout until 2025, during which all 18 dispensing locations were converted to RFID-supported processes.

In the next step, an RFID portal expanded the recording to include entire laundry carts, making the logistics flow, laundry throughput, and tracking transparent. Finally, an automated dispensing cabinet was integrated, enabling 24/7 dispensing and return and completing the closed-loop process without media discontinuity.

"The introduction of control and automation processes has eliminated all time-consuming tasks. Manual sorting and counting of dirty laundry, which previously took an average of 1.5 hours per day, is now no longer necessary. The information system allows a list of dirty laundry sent to the laundry to be printed out." - Dr. Danijela Kralj, Head of Supply Services, University Medical Center Ljubljana.

Partners

In the first phase of the project, ŠPICA, d.o.o. took over the development and implementation of the RFID system. This was followed by the second phase under Cetis d.o.o. with a system update and the introduction of an RFID portal for recording complete laundry carts.

In the third phase, INTERPART, d.o.o. integrated the cabinet for the automated dispensing of work clothes.

"The biggest organizational challenge was coordination between internal teams and external partners—typical for projects that touch on IT, logistics, laundry, and care at the same time." - Dr. Danijela Kralj, Head of Supply Services, University Medical Center Ljubljana.

Daily HR sync and RFID-based tracking

The system is connected to the HR department. Employee data (name, personnel number, department) is updated daily. During initial provisioning or distribution, clothing types, sizes, and target quantities are recorded per person and by department.

RFID tags enable each garment to be uniquely assigned to the inventory and – temporarily – to an employee account. The laundry trolley portal records containers during transport, making full and empty runs, cleaning cycles, and quantity rotations transparent.

From check-in to analysis

At the distribution point, the team identifies new employees by name or personnel number via the ID/HR interface; the system provisions profiles, sizes, and target quantities. Regular distribution is parameterized: limits are stored for each type of garment, removal is carried out via UHF RFID scan, tag events are generated in the transaction log, and a complete audit trail is provided – quickly, with few errors, and in a traceable manner.

When items are returned for cleaning, they are scanned again, assigned to the laundry trolley via the portal gate, and transferred to the cleaning cycle; movements and status changes are telemetered in real time. For shift operation, the 24/7 dispensing machine ensures a seamless supply, including access control, inventory monitoring, and low-stock alerts.

At the same time, the reporting/analytics layer aggregates inventories, circulation quantities, disposals, and cleaning status into KPIs and dashboards; APIs provide the data for planning, SLA monitoring, and forecasting. The result is a closed, data-centric, closed-loop textile logistics system that controls processes and secures decisions in real time.

Real-time KPIs in the textile cycle

Since introducing the RFID system, the University Medical Center Ljubljana has noticeably accelerated its workwear management processes while also making them more reliable. The previously manual steps have been replaced by automated recording, which has reduced waiting times and walking distances and made the issuing processes much smoother.

This is based on a consistent database: each garment is uniquely assigned, employee data is synchronized daily from the HR department, and inventories can be tracked across all stations in near real time. This creates end-to-end transparency – from individual removal to the issuing room to transport and cleaning.

At the same time, the entire life cycle of the clothing becomes visible: which items need to be sorted out, which are in the dry cleaner's or being returned, and which have been sent for alterations. This visibility leads to realistic, data-based demand planning and prevents over- or under-coverage when making new purchases.

Real-time validation: right items, right person, verifiable

The solution also sets new standards in terms of safety, hygiene, and compliance. Process steps that were hygienically sensitive and organizationally complex—such as pre-sorting and counting soiled laundry—have been largely eliminated or clearly structured thanks to RFID-supported processing.

The system reliably detects when garments are accidentally assigned to the wrong person or returned to the wrong account, improving traceability and making errors visible at an early stage. The paperless, digitally auditable process creates reliable evidence for internal controls and external audits and enables in-depth analyses of everything from consumption profiles to peak times.

All in all, speed, data quality, and hygiene combine to form a stable, traceable process chain that relieves the burden on clinical operations, reduces risks, and manages resources in a targeted manner.