- Accurate RAIN RFID data depends on antennas designed to handle project specific environmental challenges like metal, liquids, and tag orientation.

- Times-7’s engineering approach integrates design, manufacturing, and testing to deliver consistent antenna performance from prototype to deployment.

- A broad standard antenna portfolio can address most fixed RFID applications, minimizing the use of custom designed solutions to projects with unique requirements.

- Custom antennas are essential for specialized installations requiring precise read zones, compact form factors, or specific RF characteristics.

RAIN RFID promises visibility, speed, and confidence. Yet anyone who has commissioned a real system knows the uncomfortable truth: the hard part is not getting a read, it is getting the right reads, every time, in a space that is never as clean as a lab. Metal shelving reflects. Liquids absorb. People move unpredictably. Tags tilt, stack, and overlap. And the data that operations depend on is only as good as the read zone you actually create.

That is why antennas matter more than most projects admit at the start. Antennas do not merely “transmit and receive.” They shape where the system can see, how cleanly it can discriminate, and how stable performance remains when reality gets messy. Times-7 has built its reputation by focusing on that exact boundary where RFID theory meets operational constraints.

As RFID Engineer Daniel Eisen explains, “Times-7 positions itself within the RFID ecosystem as an antenna specialist, with deep RFID expertise to maximize data quality in RFID systems.”

Built Under One Roof

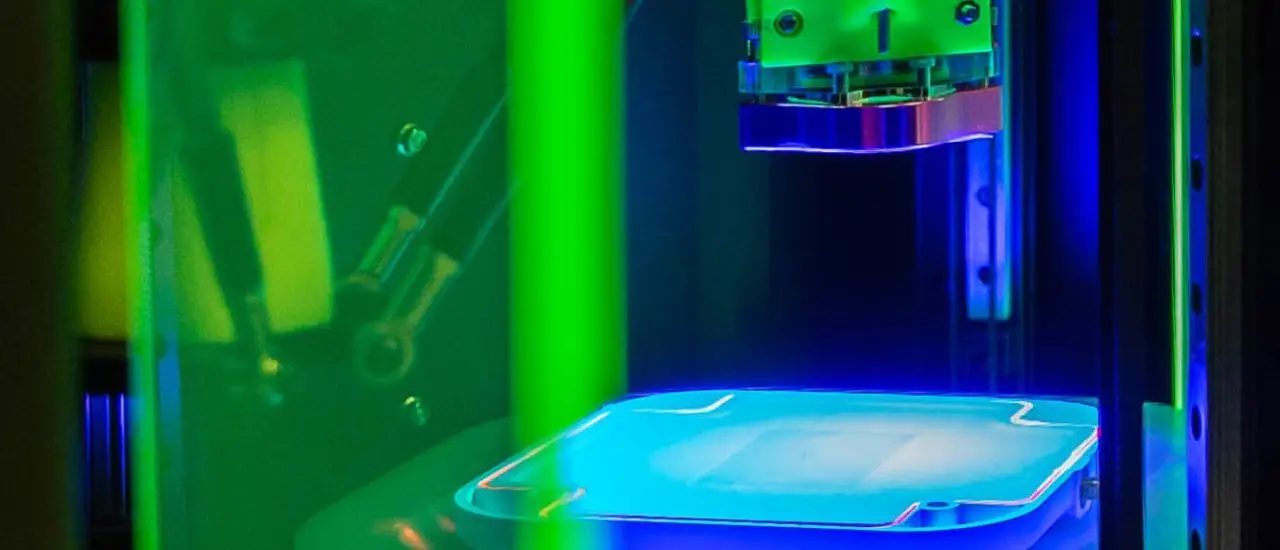

In RFID, speed is not just about read rates. It is about how quickly a solution can move from concept to something that works reliably in a customer’s environment. Times-7’s advantage is that development, prototyping, testing, and series production sit together.

Proximity tightens feedback loops, shortens iteration cycles, and helps ensure that quality is not an afterthought but a built-in discipline.

This setup also enables the rapid development Times-7 is known for in the market: high performance fixed RAIN RFID antennas and a track record of innovative form factors, including ultra-flat low -profile antennas designed for permanent installation where space is limited and mounting needs to be discreet.

The point is not thinness for its own sake. Thin, robust designs often unlock use cases where standard housings would be impossible to integrate cleanly, especially in retail fixtures, smart cabinets, portals, and devices where the antenna must disappear into the infrastructure.

The practical outcome is consistency. When engineering, manufacturing, and testing are aligned, the antenna you specified remains the antenna you receive, and the antenna you received behaves like the antenna you tested. That consistency is what integrators and end-users ultimately buy, even when they think they are buying “just hardware.”

A Standard Portfolio Designed for Real Deployments

Most RFID projects should begin with proven options. The fastest path to performance is often selecting the right standard antenna that already reflects lessons learned across many installations. Times-7 takes that seriously, maintaining a portfolio broad enough to cover the majority of fixed RFID applications without forcing customers into unnecessary custom work.

Daniel Eisen puts numbers to that breadth: “We have one of the largest standard portfolios of antennas on the market, around 40 unique antennas and up to 200 different SKUs, if you include colors, connectors, and cable variants.”

That variety matters because the antenna is rarely the only constraint. Installers need mounting flexibility. Industrial sites need durability and environmental resilience. Retail needs clean integration and controlled read zones. Healthcare and logistics require reliability in spaces that are busy, reflective, and time-sensitive.

A strong standard portfolio also supports better project conversations. Instead of jumping straight to “custom,” customers can start with a clear baseline and only escalate to new antenna designs when the use case truly demands it. That is how smart deployments scale: with a solid foundation that reduces risk, shortens commissioning time, and provides predictable performance.

A9044M Packing Station Antenna

The A9044M antenna provides reliable, high-speed RAIN RFID reading to optimize item-level packing and verification in logistics operations.

When the Standard Reaches Its Limits

There is a point in many ambitious deployments when standard products, however good, no longer fit the job. This is not failure. It is simply the reality of physics and integration. When the mechanical requirements tighten and the RF requirements become specific, the antenna must become part of the product or infrastructure rather than an external component.

Times-7 sees this transition clearly because it happens in the same patterns across industries.

Daniel Eisen describes the boundary between standard and custom in straightforward terms: “Our standard antennas are standalone products with housings, generic connectors, and compatibility with standard cables and readers. However, when a customer says: ‘The antenna must fit into this shelf, scan chamber or device, be only a few millimeters thick, and meet very specific mounting or installation requirements,’ then it is clear that many standard features no longer fit the bill.”

That is the mechanical side. The RF side can be even more decisive. Some applications demand tight read zone specificity, unusual directivity, or high performance in highly reflective environments like cabinets, tunnels, and dense shelving.

Others involve materials that challenge RF behavior, including metal-rich surroundings or items with significant liquid content. In those scenarios, the antenna cannot simply be “powerful.” It must be precise. It must produce the right field shape and maintain stable behavior when conditions vary.

It is also important to understand why custom matters strategically, not just technically. While custom projects typically represent a smaller share of overall unit volume compared to standard sales, they often enable the most demanding and high-value deployments. They push the limits of integration and performance, and they produce learnings that can influence future standard designs. In other words, custom work is not a sideline. It is one of the engines of next-generation capability.

Engineering the Outcome: From Requirement to Verified Performance

A custom antenna is only successful if it performs in the real system, not only in idealized measurement conditions. Times-7 approaches development as an engineering partnership, where RF requirements, mechanical constraints, and the operational definition of “success” are aligned early.

The process begins with understanding what the customer is truly trying to achieve. Not just read range in open air, but what must be read, what must not be read, how tags move, how densely they appear, and what the environment does to RF behavior.

Testing sits at the center of that process. Daniel Eisen explains how his role connects tools, procedures, and real-world simulation: “A large part of my work involves managing our test equipment and the associated test procedures.” He continues, “We carry out classic RF tests and we perform comprehensive functional tests. Basically, we use RFID readers, antennas, and tags to build a simulation of our customers’ systems. This allows us to test antennas from both a physical-technical and an operational perspective.”

That dual lens is essential. Classic RF testing helps characterize radiation patterns, gain behavior, and field distribution. Functional testing answers the questions that matter during commissioning: Does the read zone behave as intended when tags arrive in messy orientations? Does performance remain stable when objects shift nearby? Is the system reliably discriminating between intended reads and incidental reads?

In many cases, Times-7 will reproduce key elements of the customer’s setup internally. In others, customers send equipment or fixtures at different stages so the antenna can be tuned within the context of the host system. This collaboration reduces surprises, shortens the path to deployment, and turns “integration risk” into a structured engineering activity instead of an unpredictable field struggle.

The larger message is that antenna performance is not a single number. It is the sum of interactions between tag behavior, environment, reader configuration, and mechanical integration. Times-7 designs with that system-level reality in mind, aiming for dependable data rather than impressive specifications in isolation.

New Zealand Pride, Global Relevance

Times-7’s New Zealand base is not presented as a novelty. It is presented as a point of pride and a foundation for how the company operates: close alignment between design and build, disciplined quality practices, and the agility to iterate quickly when customers need answers.

From that base in Lower Hutt, Times-7 supports deployments around the world, from straightforward read points to demanding multi-antenna systems where read accuracy is a business-critical metric.

RAIN RFID keeps moving into more complex environments and more embedded applications. As it does, the antenna becomes less like a component you pick from a list and more like a performance instrument you integrate with intention. Times-7’s message, through both its standard portfolio and its custom capabilities, is that high-quality RFID data is engineered. It is not assumed.

And if you are facing a real-world RFID challenge where the read zone, the environment, or the integration constraints are pushing standard options to their limits, Daniel Eisen and the Times-7 team are keen to hear from you.

They welcome direct contact to discuss requirements, explore feasibility, and help translate your application goals into antenna performance you can trust.

-13-3-25-responsive.webp)