- Ultrasonic sensors detect stacked empty containers and automatically trigger driverless transport systems when a predefined height is reached.

- LoRaWAN provides energy-efficient, reliable indoor wireless communication with good building penetration and easy IT integration.

- WILSEN.sonic sensors offer accurate measurement, up to ten years battery life, IP66/67 protection, and remote configuration.

- The solution is retrofit-ready and requires no additional cabling, structural changes, or extra software licenses.

- Deployment reduces manual workload, prevents production interruptions, and scales across multiple production areas for broader logistics optimization.

A globally leading helicopter manufacturer has taken a significant step toward digitized production. Together with Pepperl+Fuchs, a wireless solution was implemented at a German production site that automates the management of empty load carriers – energy-efficient, cable-free, and fully integrated into existing workflows.

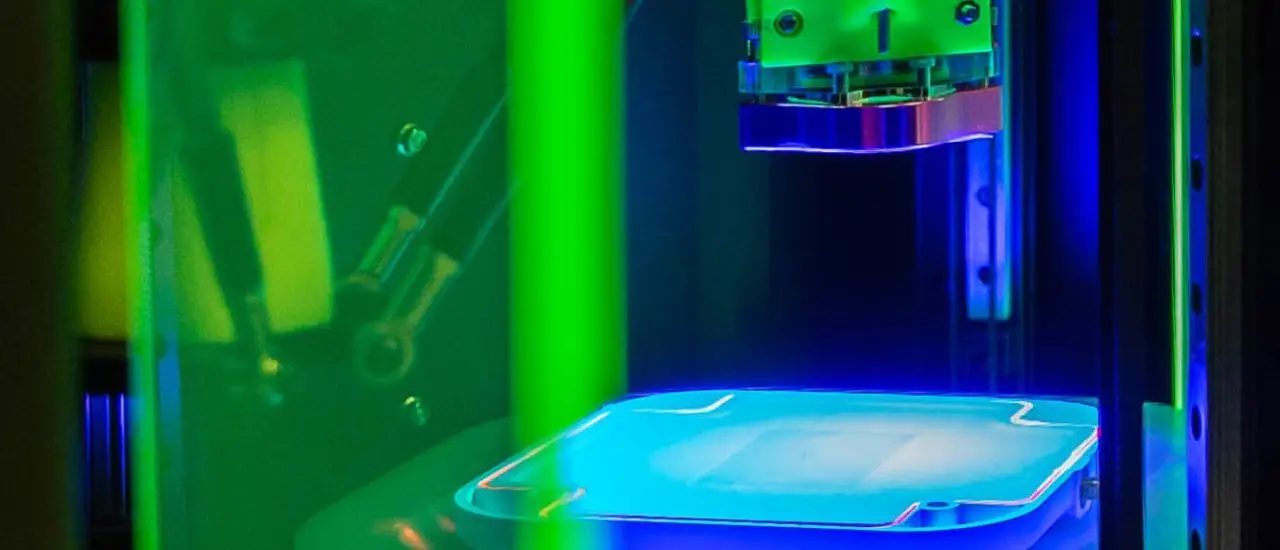

At the core of the system: precise ultrasonic sensors and the proven LoRaWAN wireless technology for indoor industrial environments.

The Challenge: Empty Boxes Disrupt Production Flow

At the German site of the aerospace group, assembly teams receive components delivered in boxes. Once the parts are installed, the empty containers must be removed quickly. Previously, this step was initiated manually by pressing a button to request driverless transport systems (DTS). This was inefficient and frequently interrupted the tightly synchronized assembly line.

The Solution: Automated Empty Container Handling with LoRaWAN

Today, this process runs automatically – enabled by wireless ultrasonic sensors and reliable LoRaWAN communication. Once a predefined height of stacked empty boxes is detected, the system autonomously triggers the DTS. The containers are picked up, and an empty trolley is provided – with no manual interaction required.

LoRaWAN has proven to be an ideal technology for such scenarios. It is energy-efficient, offers reliable building penetration, and can be easily integrated into existing IT systems – making it especially suitable for industrial indoor use.

Note: Ultrasonic sensors operate using sound waves above 20 kHz and determine distances by measuring the time delay of reflected signals. They detect objects regardless of color, material, or lighting conditions and are ideal for industrial environments.

Focus on WILSEN.sonic – The Sensor Solution from Pepperl+Fuchs

The key to automation lies in WILSEN.sonic ultrasonic sensors. Developed specifically for industrial IoT applications, they offer:

Accurate measurement even with changing lighting or surface conditions

Battery-powered operation for up to ten years – ideal for autonomous deployment

Rugged design compliant with IP66/67 – reliable in harsh industrial environments

Full connectivity via LoRaWAN – no external power or network wiring required

Remote configuration via downlink – adjustments can be made from anywhere

Why the System Stands Out

Reduced manual workload: No more pressing buttons – the system takes over.

Increased production reliability: Empty containers no longer obstruct workspaces.

Retrofit-ready: Wireless sensors require no structural modifications.

Scalable implementation: Can be deployed wherever empty containers occur.

“Install, Activate, Unburden” – Interview with Daniel Möst, Pepperl+Fuchs

Daniel Möst, Technology Manager at Pepperl+Fuchs, shares insights into real-world application:

What makes WILSEN.sonic particularly suitable for industrial use?

Daniel Möst: Our sensors operate reliably, energy-efficiently, and completely autonomously – which is a huge advantage in industrial settings. They can be installed where other solutions fail due to the need for power supply or cabling. Thanks to precise measurement data, the system reacts exactly when it should – not earlier, not later.

Our sensor solution delivers where others fail – fully autonomous, precise, and seamlessly integrated into existing processes.

Daniel Möst - New Business Development Manager

How does the solution integrate into existing infrastructure?

Daniel Möst: The sensors connect directly to existing LoRaWAN networks – no extra software licenses or infrastructure costs. They can also be configured and monitored remotely, saving time and enabling full control even across complex production sites.

Conclusion: Rethinking Industrial Empty Container Management

This implementation shows how wireless sensor technology solves real-world challenges. The management of empty load carriers becomes automated, ensuring uninterrupted production flow. The combination of LoRaWAN and WILSEN.sonic not only delivers technical reliability but also economic value – a clear step toward smarter industrial logistics.