- OPC UA enables secure, interoperable communication connecting millions of data points in Austria’s tunnel systems.

- The technology supports high availability with built-in redundancy essential for tunnel safety and rapid incident response.

- ASFINAG and evon utilize OPC UA together with the evon XAMControl platform for centralized monitoring and control.

- Austria’s tunnel infrastructure includes around 170 tunnels integrated into a comprehensive traffic management system using OPC UA.

- Future plans involve expanding OPC UA integration to condition monitoring and external systems for uniform data management.

Millions of data points and sensors are connected and centrally managed with OPC UA.

Austria’s tunnels are among the most complex in Europe. Where safety is paramount, ASFINAG, together with technology partner evon, relies on OPC UA to enable reliable, interoperable communication across diverse systems—secure, standardized, and redundant—scaling from pilot projects to millions of data points while keeping operations transparent and controllable across the high-level road network.

Markus Winter, Team Leader for Tunnel & Open-Road Services, at ASFINAG, and Daniel Seewald, Head of Tunnel & Traffic Infrastructure at evon, tell the story behind this rollout.

OPC UA for Austria’s Tunnel Network

ASFINAG and evon: from pilot to VMIS 2.0

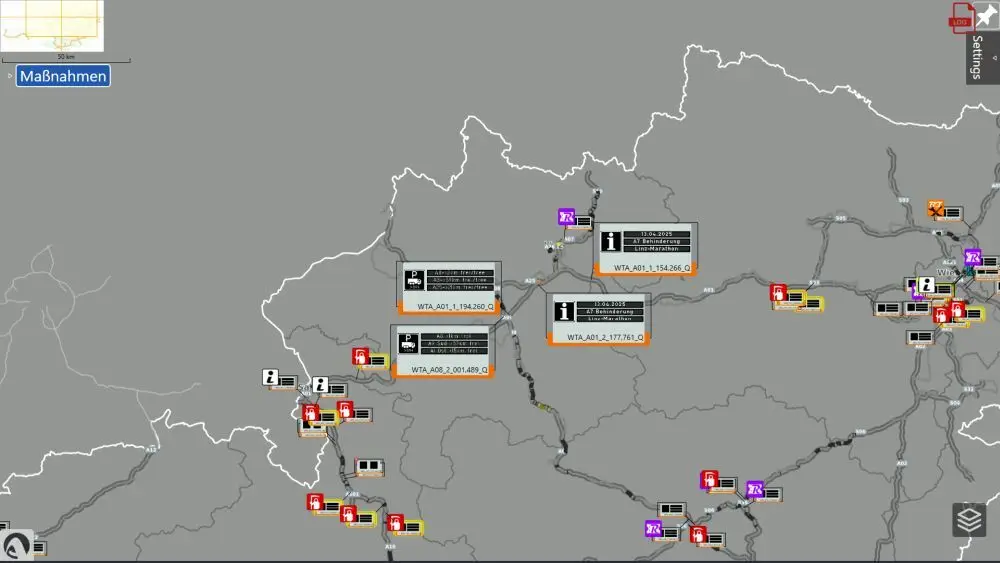

Since 2018, evon has been part of an international consortium commissioned by ASFINAG to develop the VMIS 2.0 traffic management and information system. The platform integrates over 33,000 traffic facilities, including around 170 tunnels, and lays the foundation for future vehicle-to-infrastructure (V2I) communication.

Leveraging core strengths in industrial automation, process and production control, building automation, traffic and tunnel infrastructure, and energy management, evon delivers its platform evon XAMControl, spanning SCADA, DCS (SCADA + virtual PLC), and MES applications.

Where safety counts: Communication in tunnel operation

Reliable and interoperable communication is of crucial importance, especially in tunnel operation, where sensors, control systems, and safety mechanisms interact. This is where OPC UA comes into play.

Since an initial pilot project in 2016, OPC UA has been established as the central technology in Austria's tunnel monitoring systems. In today’s solution, OPC UA as a highly scalable technology connects millions of data points. Its greatest strengths are platform-independent interoperability, end-to-end security, standardized semantic information models, and built-in redundancy for high availability.

“Every second counts in Austria's tunnels – that's why we rely on communication that is secure, interoperable, and redundant.”

Markus Winter, Team Leader for Tunnel & Open-Road Services at ASFINAG

Alpine topography, dense tunnel infrastructure, and transit traffic

The increasing digitalization and automation in tunnel operation is also a response to the enormous complexity of Austria's transport infrastructure. Alpine topography, a dense tunnel infrastructure, and high transit traffic characterize the requirements for planning, operation, maintenance, and monitoring.

Why is tunnel operation so critical in terms of safety?

Tunnels are very demanding in terms of safety and monitoring. After all, they are enclosed spaces that are difficult to access and where rapid intervention is limited in the event of an emergency. In the event of incidents such as fires, accidents, or technical failures, smoke, heat, and toxic gases can become dangerous.

Therefore, systems such as ventilation, lighting, fire alarm and extinguishing systems, traffic control technology, and emergency call systems must be optimally coordinated. Precisely because the systems often come from different manufacturers, smooth and error-free cooperation between the systems is of crucial importance.

Conclusion: Modern tunnel systems place the highest demands on operational safety. The standards for communication, monitoring of all measured values, and seamless integration of all involved systems are correspondingly strict. EU directives and national regulations such as the Tunnel Directive prescribe regular inspections, renovations, or digital retrofits.

Technical systems in tunnels

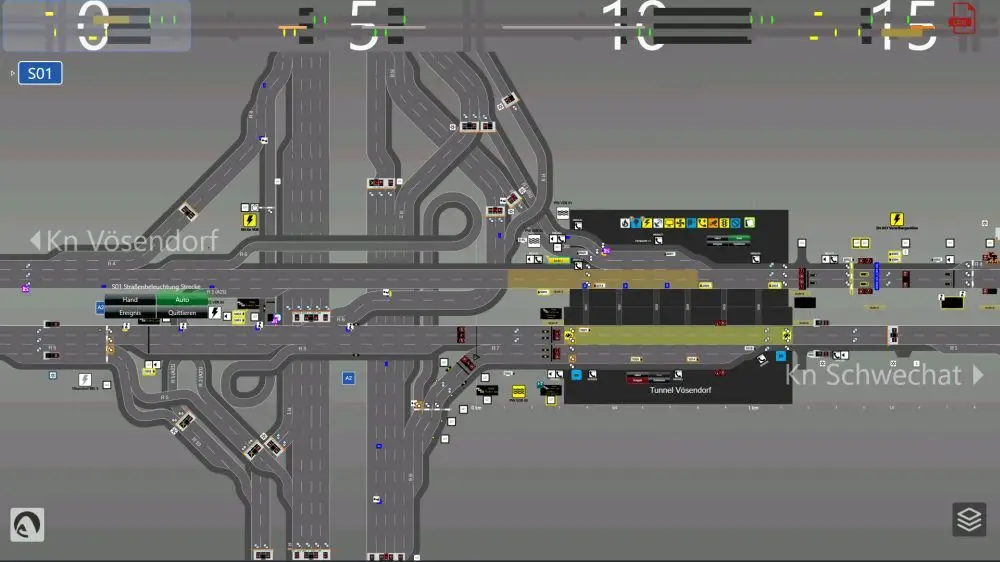

The collaboration between ASFINAG and evon has proven its worth in a wide range of technical tasks that need to be implemented in modern tunnels. The systems must be installed and networked and controlled via central platforms such as evon XAMControl. A look at this complex infrastructure highlights the challenges – and the importance of reliable automation.

Modern road tunnels are equipped with a variety of technical systems. Safety and fire protection systems are central components. These include fire alarm systems, smoke and heat extraction systems, automatic fire extinguishing systems, emergency call systems, escape route lighting, and emergency lighting that also works in the event of a power failure.

Ventilation and smoke extraction systems are also part of the technical equipment. Air quality is continuously monitored by sensors. Traffic and operating technology includes variable traffic signs, barrier systems, and light signals. They react dynamically to traffic volume and hazardous situations. Video surveillance cameras and automatic systems for detecting traffic jams and accidents continuously provide information to the central control system.

Control is via a SCADA system. Responsibility for control and regulation lies with the tunnel builders, who integrate their systems into local control units. These decentralized units are in constant communication with the regional traffic management centers, which monitor the 24/7 operation of the tunnel facilities.

2016: OPC UA integration begins

First field study with OPC UA: Tunnel in Carinthia as a pilot project

The collaboration with evon and the introduction of OPC UA date back to 2016. The communication standard had already been applied in earlier plant projects. evon implemented the control and visualization system.

The first dedicated use case for testing and evaluating the OPC UA communication standard was the integration of a tunnel chain with four technical facilities in the Klagenfurt am Wörthersee region. This pilot assessed its suitability for widespread use in tunnel monitoring.

Comparison of OPC UA with other telecontrol protocols

The decision to roll out OPC UA in full was made after an evaluation phase in which OPC UA was compared with the IEC 60870-5-104 and IEC 61850 telecontrol protocols. The decisive factors were, in particular, the continuous further development of OPC UA and the structured possibilities for object-oriented data modeling.

Since 2016, OPC UA has become the standard protocol for data integration at ASFINAG. The positive experiences from the pilot project in Carinthia and the successful scaling from an initial 50,000 to around 6.5 million data points confirmed the technical and strategic decision.

Technological aspects and advantages of OPC UA integration

How ASFINAG uses OPC UA

OPC UA is used at ASFINAG as the central communication protocol to network control systems, sensors, and safety devices across systems in a secure and interoperable manner. Standardized data modeling and manufacturer-independent communication provide a clear advantage for tunnel operation. OPC UA connects different systems and thus supports the monitoring and control of tunnel facilities.

The system is supplemented by the XAMControl platform from evon. The platform handles data aggregation and visualization.

Redundancy is mandatory for tunnel monitoring systems

The tunnel systems are connected to the monitoring systems via OPC UA. Thanks to standardized data modeling, systems from different manufacturers can be integrated and monitored centrally. This provides operators in traffic management centers with precise information on operating conditions, malfunctions, and maintenance requirements.

OPC UA integration covers a wide range of system types. These include ventilation and lighting systems, fire alarm systems with sensors, emergency call systems with SOS buttons and monitors, traffic control systems, energy and video surveillance, and fire extinguishing systems. Transformers, switching states, and automatic circuit breakers in energy technology are also integrated. However, water protection, firefighting water, and ventilation systems are not yet connected across the board.

For historical reasons OPC UA Data Access is used to transmit fault and alarm messages, sensor values, operating and diagnostic data, and control commands. This function can be used to monitor switching states, query maintenance cycles, or change operating modes in a targeted manner.

The underlying data models are based on the ASFINAG object catalog, which was created during the implementation of the first projects and is constantly being expanded. This standardized modeling ensures consistent processing of all relevant data within the tunnel infrastructure.

IT security and integration: Object modeling

Tunnel systems in Austria are subject to strict IT security requirements. OPC UA supports various authentication methods, such as user password models and certificate-based authentication, enabling these requirements to be implemented. These mechanisms serve to control access to the systems and protect against external attacks.

In addition to security-related aspects, object-oriented data modeling plays a central role in the integration of tunnel technology. System components are integrated using a predefined object catalog, which ensures a uniform structure and representation of the transmitted data. OPC UA Data Access is currently the main implementation method, while other functions of the protocol stack, such as method calls or direct access to archive and alarm data, are not yet in use.

Standardized modeling facilitates the integration of technical systems and enables consistent visualization of operating states in the monitoring systems. This reduces the effort required for engineering processes, which in turn frees up more resources for testing and quality assurance.

Uniform data structure for diverse stakeholders

A key advantage of OPC UA is its standardized and clearly understandable data structure. Different contractors and system manufacturers supply data in a uniformly modeled form, enabling consistent monitoring. ASFINAG operates the central monitoring system, into which all systems must be integrated before acceptance, and does not act as an intermediary.

All data – currently around 6.5 million data points – converge on a redundant server in Vienna. From there, they are additionally distributed to nine regional traffic management centers. This decentralized architecture ensures reliability and enables so-called self-sufficient operation: if the connection to the headquarters in Vienna is interrupted, operations within the respective region can be maintained independently.

Nevertheless, decision-making processes remain centrally organized, as all operational processes are controlled via the main server in Vienna. The regional servers ensure operational capability in the event of a malfunction. This combination of central control and regional backup strengthens the operational reliability of the tunnel infrastructure.

How exactly are the systems connected with OPC UA?

To ensure operational reliability when connecting tunnel systems, the connections between the regional traffic management centers and the tunnel systems are always designed to be redundant. By using the redundancy mechanism of OPC UA, in particular by reading the redundancy status via the "ServiceLevel" variable, the status of each communication counterpart can be precisely evaluated.

The ServiceLevel value is partitioned into defined ranges that indicate data-source health and server load, not a general operating status. In OPC UA redundancy scenarios, both servers and clients use this information: servers expose ServiceLevel, and clients use the redundancy mechanisms for load balancing and failover.

Future plans for tunnel systems in Austria

Incremental scaling of the tunnel infrastructure with OPC UA

A milestone was reached with the commissioning of the last traffic management center in Hohenems in May 2025. However, further integration steps are still to come, as each tunnel facility is renovated every ten years and then reconnected. The number of sensors and safety components is continuously increasing. Although this continuous expansion no longer leads to exponential growth in OPC UA data points, it does allow the system landscape to continue to grow gradually.

„OPC UA ist unser Rückgrat für Interoperabilität: sichere Authentifizierung, klare Informationsmodelle, herstellerunabhängige Integration.“

Daniel Seewald, Head of Tunnel & Traffic Infrastructure at evon

Future: Condition monitoring in tunnel operation with OPC UA

Condition monitoring is playing an increasingly important role in tunnel operation, especially in the continuous evaluation of sensor data. Currently, this data is often still collected via analog signals or external third-party systems that use protocols other than OPC UA. OPC UA has already been successfully introduced between tunnel control and the monitoring center.

In the long term, ASFINAG aims to gradually standardize the connection of these external systems via OPC UA as well. The experience gained in the main system to date is now to be transferred to the area of condition monitoring in order to create a uniform and interoperable database for the entire tunnel operation.

Major tunnel projects in Austria

ASFINAG is currently working on several major tunnel projects in Austria. These include the Golling–Werfen tunnel chain on the A10, which consists of five tunnels. The renovation of this tunnel chain was completed in June 2025. Renovation work on the Tauern and Katschberg tunnels is then on the agenda.

Another project is the construction of the second tube of the Karawanken Tunnel on the A11. This tunnel will connect Austria with Slovenia. Completion of the new east tube is planned for spring 2026. The existing tube will then be completely renovated so that both tubes can go into operation in summer 2028 as planned.

Several tunnel sections on the A26 Linz motorway are being renovated. The Danube Valley Bridge was completed in 2024, the Freinberg Tunnel will follow in 2026, and completion is planned for 2032. The subsequent construction of the West Bridge will be completed in 2035.

Another major project is the complete renovation of the section between Haiming and the Roppener Tunnel on the A12. Investments of over seven billion euros are planned for this project by 2027.

ASFINAG in facts and figures (as of 2024)

Investments: €1.519 billion in transport infrastructure

Toll network: 2,266 km of motorways & expressways

Main infrastructure

5,862 bridges

170 tunnels

6 toll stations

9 traffic management centers

43 motorway maintenance depots

385 junctions

Supplementary infrastructure

87 service stations

59 rest areas

106 parking lots

10,375 truck parking spaces

72 park-and-ride facilities

Source: The case study can be found on the OPC Foundation website at https://opcfoundation.org/resources/case-studies/.