- Integrated Neosid RFID transponders remain readable after exposure to depths beyond 6,000 meters when vacuum-cast without trapped air.

- Embedding the tag during production provides unique, lifetime identification linking serials, batches, and test records for each thruster.

- Tag-enabled traceability enables targeted failure analysis, planned part replacement, and reduced unplanned offshore downtime.

- The integration requires minimal production changes but delivers high value for low-volume, high-criticality marine propulsion systems.

6,000 meters below the sea surface is no place for approximations. Down there, the pressure is several hundred bar, it is dark, cold, hostile – and mistakes quickly cost a lot of money. Anyone who wants to work in this environment needs technology that not only "works" but is also permanently reliable.

This is precisely where two specialized worlds meet: Copenhagen Subsea's electric ring-driven underwater propulsion systems and Neosid's pressure-resistant RFID transponders.

From a failed standard solution to a proprietary drive

This story started not with a concept, but a challenge in the field.

Around 15 years ago, the founding team led by Henrik Neuschäfer Larsen was working on an ROV for ship hulls.

The concept was clear, but the available underwater propulsion systems failed the endurance test: they were not robust enough, not durable enough, and not designed for hours of high-load operation in close proximity to the ship's hull, in currents, in dirty conditions, in salt water, and under mechanical stress.

The consequence is radical and typical of engineers: if what we need doesn't exist, we'll just build it ourselves.

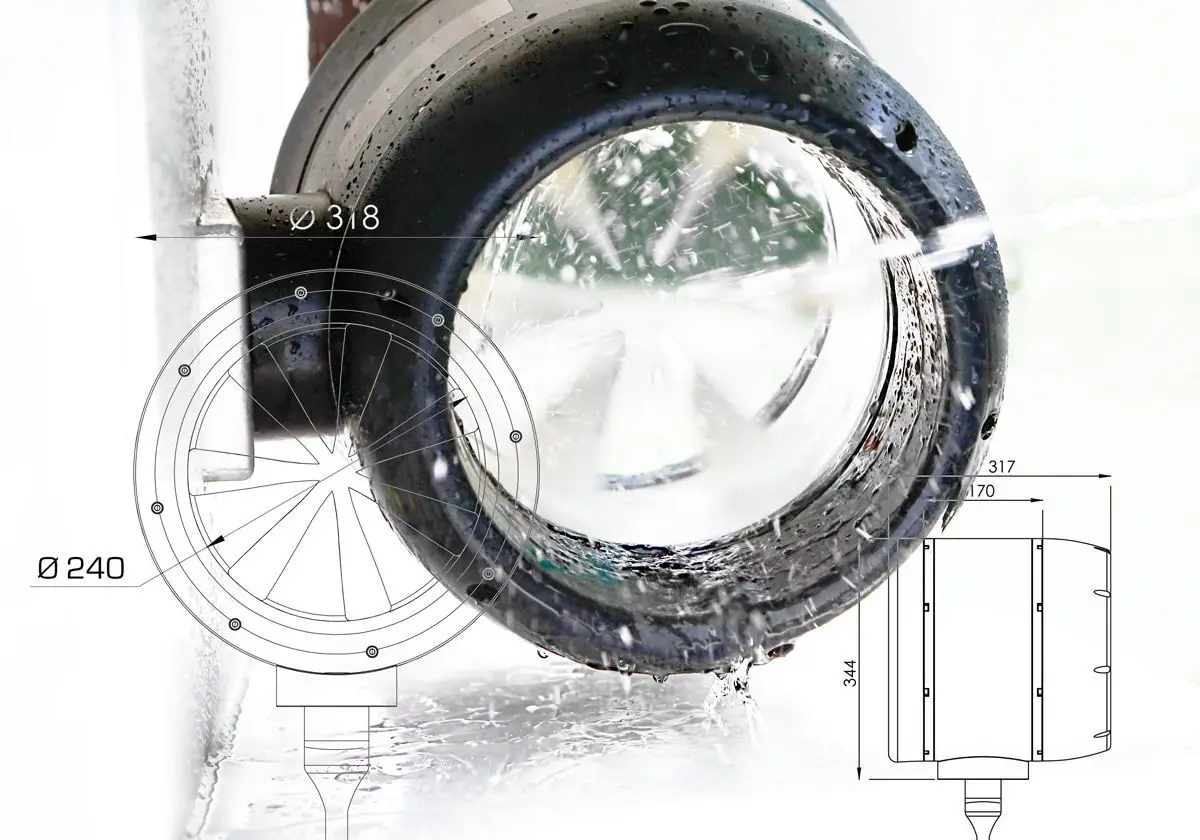

Step by step, this decision gives rise to an independent product: a ring thruster in which the motor is not located in the center but is integrated as a stator in the outer ring. The propeller runs inside, the unit is vacuum-cast and operates completely underwater – without classic shafts, without oil, without complex seals. The oil-free, fully electric design also eliminates the risk of leakage, critical in sensitive marine environments.

The result: less wear, fewer weak points, greater pressure resistance. The project gave rise to a company: Copenhagen Subsea A/S.

Today, these thrusters power ROVs, AUVs (Autonomous Underwater Vehicles), surface vehicles, and special platforms worldwide. They’re used by subsea operators, research institutions, and OEMs where failure is not an option. They are designed for extreme applications, tested for depths of over 6,000 meters – approved with a safety margin at 663 bars.

Identity under high pressure: Why an RFID tag suddenly becomes strategic

As their use becomes more widespread, another issue is growing in importance: unique identification and traceability. Each thruster consists of high-quality documented components, and all materials undergo strict quality and batch control. In the early stages of development, this helps to identify sources of error. During operation, it forms the basis for reliability and trust.

The problem: in the reality of underwater propulsion, externally attached labels, stickers, or markings often do not last. Salt water, pressure, abrasion, paint, everything works against clear markings.

The question within the team: How can we ensure that we will still know exactly which motor we have in front of us in five or eight years' time when it returns from a deep-sea project?

The answer leads to Neosid.

The solution: a transponder that is tougher than its environment

We are looking for an RFID transponder that can reliably do three things:

Withstand pressure – to depths of 6,000 m and above without imploding.

Be air-free – no trapped air that becomes a problem under pressure.

Can be integrated inconspicuously – so small and robust that it fits seamlessly into the production process.

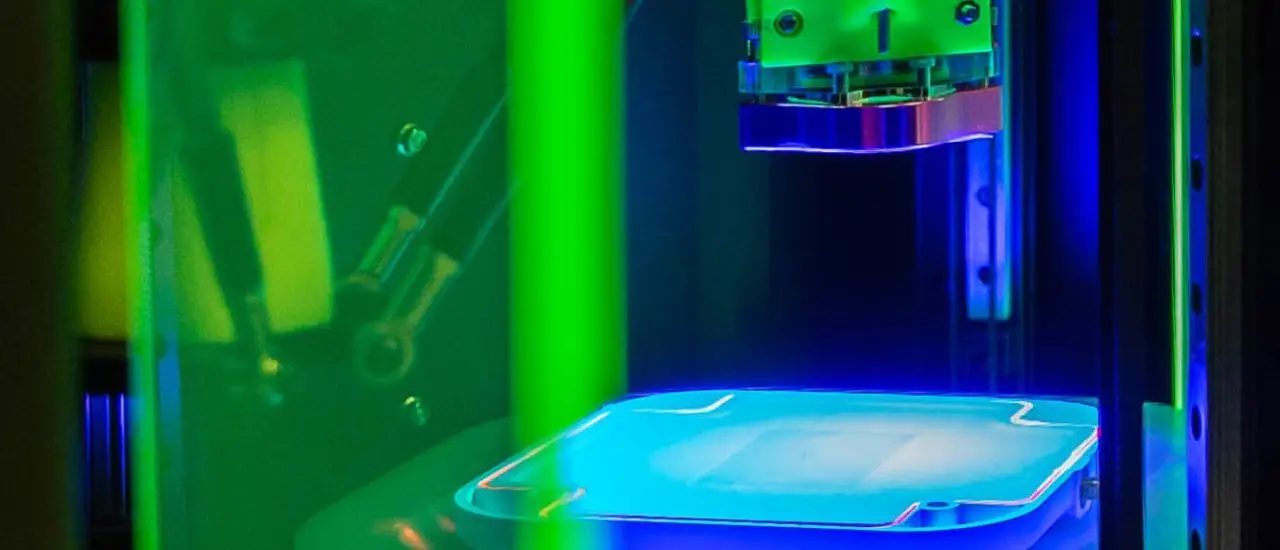

Copenhagen Subsea opts for a transponder from Neosid, which is placed directly inside the thruster during casting. The tag is invisible from the outside – there is no additional housing, no cavities, no mechanical modifications. During vacuum casting, the potting compound is degassed before curing. This eliminates air inclusions that would otherwise be compressed at depth and could cause cracks, moisture ingress, or delamination.

As a result, the transponder remains mechanically protected, electrically stable, and reliably readable even under extreme pressure. Integration is simple – but the effect is not.

When a thruster is returned to the factory, it is scanned. The RFID ID uniquely links the component to the internal documentation: serial number, batches, components used, production date, test results if applicable.

This is invaluable, especially in rare cases of damage or abnormalities: instead of guessing, it is possible to analyze specifically which batch, which production step, or which operating conditions played a role. If a thruster shows early signs of wear, the tag allows engineers to check whether similar components from the same batch were used elsewhere – helping predict issues before they happen.

This makes it possible to replace parts during planned service windows instead of reacting to failures offshore, reducing unplanned downtime and service costs. Across the fleet, the collected data also supports data-driven quality control and more streamlined service processes.

The exciting thing is that defects are rare. That's precisely why one might be tempted to say, "Is it even worth the effort?".

For Henrik Neuschäfer Larsen and his team, the answer is clear: yes.

The transponder is not a marketing gimmick or a feature for the data sheet. It is a building block in a consistent understanding of quality:

Every thruster remains identifiable throughout its entire life cycle.

Service cases can be evaluated based on facts.

Internal improvement processes are based on reliable data instead of assumptions.

Customers receive a product that is also taken seriously at the process level.

Or to put it another way: if you build propulsion systems for the deep sea, you can't stop at surface-level traceability.

Physics in the service of traceability

The fact that the Neosid transponder can play this role is anything but trivial from a technical standpoint. The thrusters are cast in a vacuum to ensure that no air is trapped inside. Air would be a risk at a depth of 6,000 meters, it can be compressed, creates tension, and could weaken structures.

The Neosid transponder (Miniature Transponder NeoTAG®) meets precisely this requirement: compact, robust, with no critical air pockets. The fact that it can withstand the same extreme conditions in real-world use as the thruster itself is part of the success story: a component normally associated with logistics, warehousing, or access control proves its suitability in one of the harshest environments in industry.

Small quantities, maximum impact

Copenhagen Subsea does not produce millions of units. It manufactures high-quality special systems for professional applications – a few hundred thrusters that are used in critical projects around the world. That is precisely why every single unit counts.

In this environment, Neosid's RFID integration does not pay off in terms of economies of scale, but in terms of safety and professionalism:

Each thruster is uniquely marked – even after years of use.

The integration effort is minimal.

The benefits in individual cases are enormous.

This is a form of "hidden champion meets hidden feature": the customer receives a highly specialized product whose internal organization they cannot see – but from which they benefit directly when servicing is required.