- The CNC milling machine improves dimensional precision to around 0.01 millimeters.

- GERA-IDENT can now produce larger PCBs (up to 750 x 900 mm) and handle medium-volume runs.

- The system processes diverse materials and supports both electronic components and housing customization.

- In-house milling reduces supplier dependency, accelerates prototyping, and shortens lead times.

- Milling avoids etching chemicals and generates recyclable metal waste, enhancing environmental performance.

In an exclusive interview, Ramin Hassan, Managing Director of GERA-IDENT, presents the newly expanded CNC milling machine that plays a key role in the company’s ongoing transformation of its production processes.

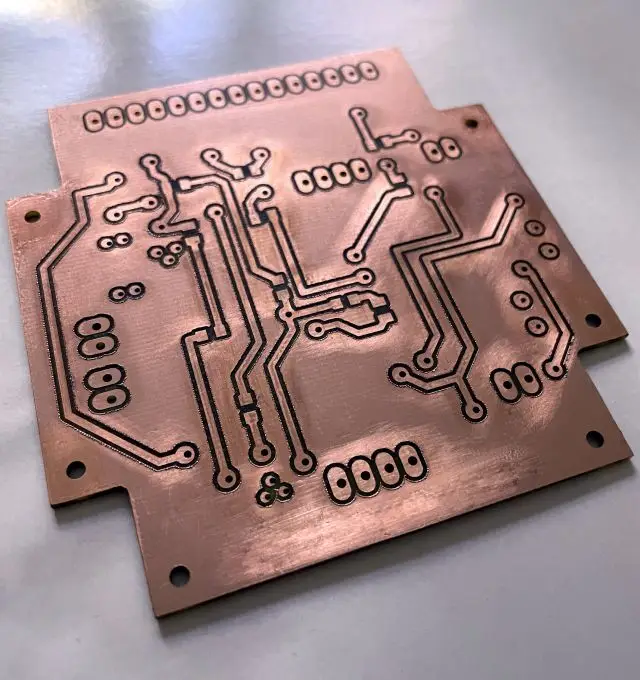

More precision, shorter production times, and consistent quality: With the new CNC milling machine, GERA-IDENT is taking the production of RFID components to the next level. From prototypes to series production, this state-of-the-art technology delivers efficiency and flexibility while meeting the highest standards for component accuracy.

Interview with Ramin Hassan

1. Why did you purchase the CNC milling machine and what specific processes will it be used for? Did the coronavirus pandemic or bottlenecks in PCB production influence this decision?

Ramin Hassan: The decision to purchase the CNC milling machine was primarily motivated by the need to further expand and flexibilize our electronics production. We wanted to optimize the production of both housing parts and electronic components such as circuit boards and antennas.

Especially during the coronavirus pandemic, when global supply chains were severely disrupted, we experienced bottlenecks. In order to continue to deliver our readers and antennas on time, we decided to purchase a system that could cover both areas.

2. What are the benefits of this system?

Ramin Hassan: The CNC milling machine allows us to efficiently produce both larger components, such as housings, and electronic components, such as antennas. Another important aspect was the environmental friendliness of the technology. In contrast to etching, milling does not produce any environmentally harmful chemicals, and the resulting waste consists of recyclable pure materials.

Whether we are producing circuit boards or metal parts, the majority of the waste is metal chips, which can be recovered and recycled.

3. What are the features of this machine and how much production capacity per week can you achieve with it?

Ramin Hassan: The CNC milling machine offers a wide range of functions. Thanks to the large number of blades and tools available, we are able to cut or mill a wide variety of materials, including plastics such as ABS or PA, but also FR4, wood, aluminum and steel.

The built-in camera system for automatic pass-mark recognition allows precise work even without exact positioning of the material.

Production capacity varies depending on the product and the complexity of the manufacturing process. Some parts take more time to produce than others, so piece counts are not always the best indicator of capacity.

The machine was originally purchased for rapid prototyping to provide faster turnaround in prototype development. Today, we also use it for small and medium production runs.

4. What specific applications are you using the machine for?

Ramin Hassan: The machine is used in both the hardware and transponder sectors. Examples include printed circuit board production and customization of standard housings and device elements.

We usually focus on RFID labels, but the machine also allows us to produce hard tags, do prototype testing, and produce up to medium quantities - several thousand units.

In the prototyping area, for example, we build adapter PCBs for large transponder chips. These small PCBs are populated with the chips and are better integrated into the final PCBs in the prototyping process, including test points and other features.

5. What specific advantages has GERA-IDENT experienced since acquiring the CNC machine in 2022?

Ramin Hassan: Printed circuit boards are typically no larger than 300 x 200 millimeters. We can now produce much larger boards - up to 750 x 900 millimeters - which greatly expands our production capabilities. We are also less dependent on antenna dimensions than before.

With a tolerance of about 0.01 millimeters, the precision is very high and corresponds to that of conventional etching technology. But we are still conserving resources and avoiding chemicals. Another advantage is that we can now perform many tasks in-house that previously had to be outsourced. This is particularly beneficial for test runs or small volumes where the development process is still unclear.

In 2022, as supply chains became more challenging, many suppliers increased their minimum quantities. We have become much more independent in this area, especially for custom orders.

We are now able to respond more quickly to custom orders and significantly reduce lead times. By performing post-processing and customization in-house, we can not only meet customer needs more efficiently, but also reduce waste and energy.

6. What are the specific advantages of combining a milling machine with a 3D printer for your production processes?

Ramin Hassan: In general, production is done in combination. When designing electronic devices, there is always an electronic part and a housing part. We mill the electronic part with the CNC machine, while the housing part is produced with the 3D printing process.

We work with several partners to make these processes efficient. In some cases, customers provide the housings directly, so we only have to integrate the electronics into the prepared housing parts.

A specific example of this is the development of sensor transponders for the medical sector, especially in the field of hygiene. Here we combine milled PCBs with 3D printed housings to provide complete transponder solutions. 3D printing allows us to quickly and cost-effectively produce custom housings in small quantities that would not be possible with traditional manufacturing methods.

The combination of CNC milling, 3D printing and our RFID expertise gives us the flexibility to respond to customer-specific requirements with a perfect fit. Talk to us - we can make your RFID solution a reality.

Ramin Hassan - Managing Director