Key takeaways

- Passive RFID sensor, no battery, up to 20 years

- Detects open/closed circuits and resistance changes

- Optimized for reliable reads on or near metal

- Supports multi-reading with RFID anti-collision

- Corrosion and contact monitoring; tamper detection

Talk to the product expert

Kamei Shohei, Technical Engineer

Detailed product information

Circuit Status RFID Tag for Long-Term Infrastructure Monitoring

This is not just a normal RFID tag, it’s a tiny passive sensor that can tell whether a connected electrical circuit is open or closed (or how its resistance changes).

This RFID tag detects the resistance of a specific circuit. As a passive tag, it is designed for maintenance-free outdoor use with a service life of up to 20 years. Optimized for operation around metal, it also offers an extended read range and naturally supports multi-reading via anti-collision protocols.

Depending on the detection target, the system can be integrated into a wide range of applications – for example, sacrificial corrosion protection systems or metal contact monitoring. With these capabilities, it is ideal for use in infrastructures and other environments where regular inspection and maintenance are required.

For a closer look, watch our introduction and demo video on YouTube.

Breakdown in simple terms

Circuit (open/close) detection

The tag is wired into or across a circuit. It measures if the circuit is intact (closed) or broken (open) – or how high the resistance is. That tells you, for example, whether something is still properly connected, corroded, or damaged.Passive RFID / no battery

The tag doesn’t need its own power source. It’s powered by the RFID reader field, so it can work maintenance-free for up to 20 years outdoors.Works well near metal

It’s specially designed to work on or around metal, where many standard RFID tags struggle. That also helps increase the read range in such environments.Multi-reading / anti-collision

Many of these tags can be read in the same area at once (e.g. dozens on a bridge or pipeline), because the RFID protocol prevents them from “talking over each other.”Typical use cases

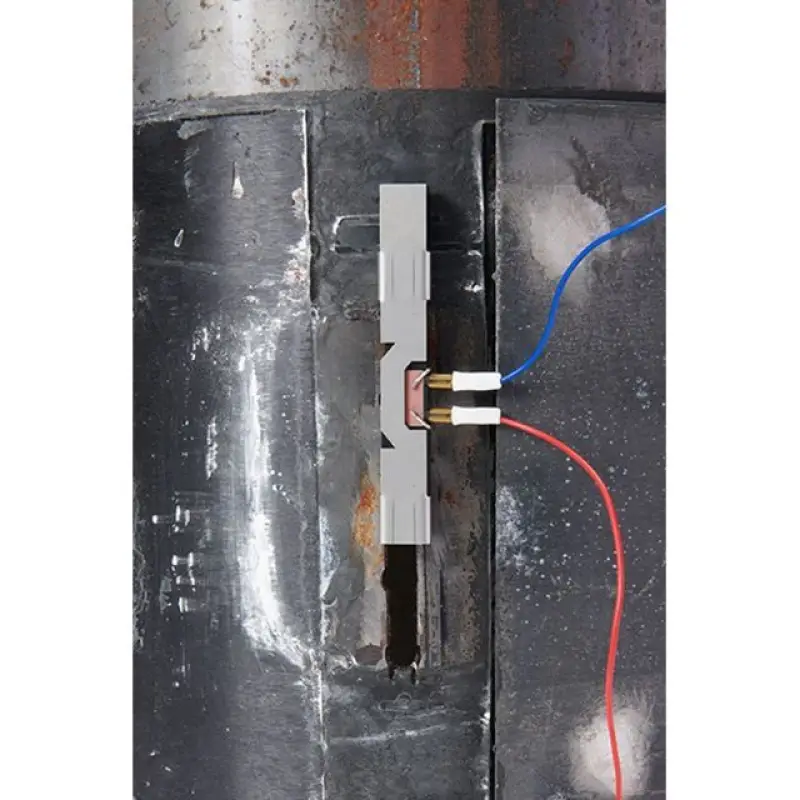

Sacrificial corrosion protection systems – to check if the protective element is still connected/working.

Metal contact monitoring – to see if two parts are still in contact or a connection has failed.

Infrastructure (bridges, pipelines, masts, rail, etc.) – places where you want to know, without manual inspection, whether something is still intact.

In practice

You walk past with an RFID reader, the tag answers with “I’m tag #123, and the circuit I’m watching is OK / not OK (based on resistance).”

Key Facts

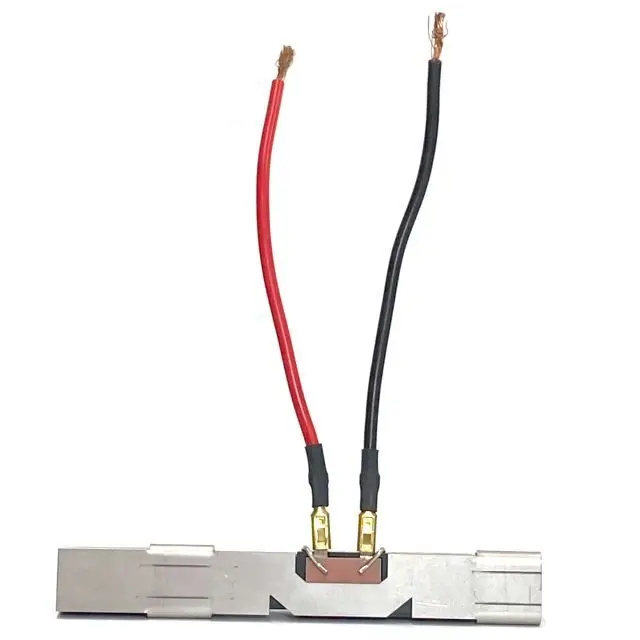

Dimensions: 120×12.5×9mm (Exclude wire cable and joint part)

Material: FR4 / Stainless steel / Polycarbonate / Wire Cable

Operating Temperature: -40℃ to 100℃

Storage Temperature: -60℃ to 100℃

Endurance Test: 85℃ 85% 2,000hour

Read range: 3~5m (1w UHF reader/depend on surroundings)

Related Products: Dual tag / Hard tag / Capacitance sensing tag / RFID Data logger

Applications: Operation detection of anti-corrosion system using electric charge contact / peeling detection of conductive materials / Tamper detection

Product Images