RFID for Workwear: Boosting Traceability, Reducing Loss, and Driving Sustainability

Managing workwear at scale—across hospitality, transportation, healthcare, or industrial sectors—poses serious logistical and sustainability challenges. From misplacement and overstocking to wasteful garment disposal, uniform management is complex and costly. Enter Primo1D’s game‑changing embedded RFID.

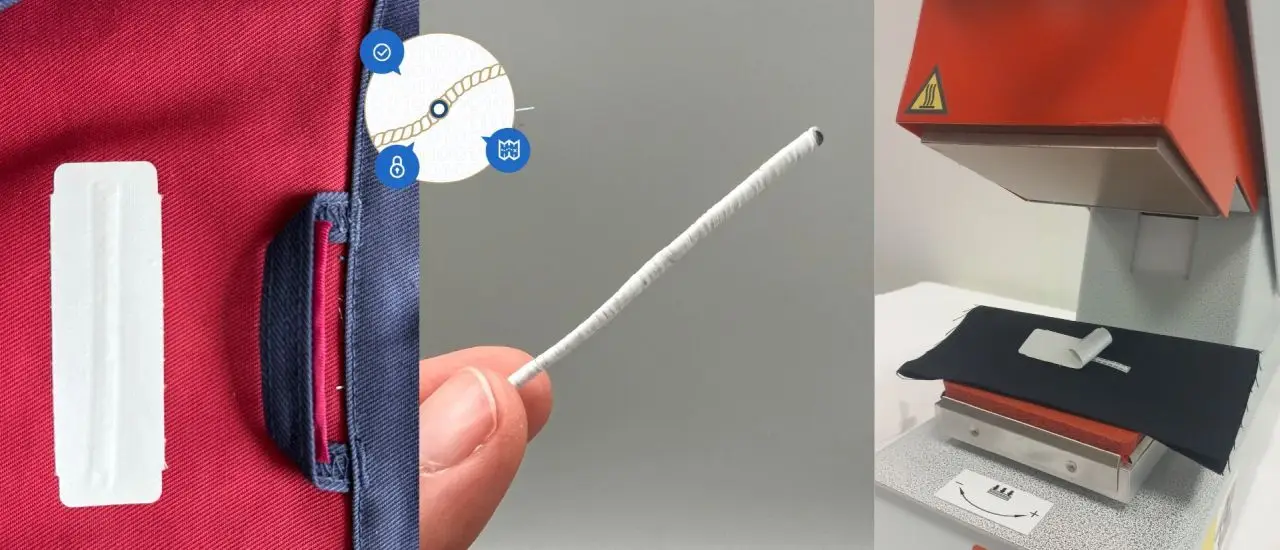

With E‑Lix and E‑strip Ws, Primo1D integrates invisible RFID tags directly into garments, making each uniform a smart, trackable asset. These embedded tags endure industrial wash cycles and stay undetectable to wearers, preserving comfort and appearance.

🎥 A new video series from Primo1D reveals how this technology transforms uniform logistics—from daily handling to circularity and recycling goals.

End‑User Insight: SNCF & Cepovett Pilot (40,000 uniforms)

A landmark pilot was recently launched with SNCF, the French national railway, and Cepovett, embedding Primo1D’s RFID yarn into 40,000 uniforms for real‑time inventory tracking.

Objective: Improve traceability across laundry, storage, distribution, repair, and recycling stages.

Implementation: Prism‑thin RFID yarn is sewn into uniforms under thermopatch labels—completely invisible and untouchable, resisting both removal and discomfort.

Durability: Tags withstand up to 50 industrial or 100 domestic wash cycles, endure high temperatures, and last through rough handling—guaranteeing consistent traceability.

Pilot Timeline: Running through end‑2025, the next expansion (up to 70,000 garments) may commence in 2026 if successful.

Value: SNCF gains massive automation in uniform handling, major time savings, and enhanced control over lifecycle management, driving loss reduction and operational efficiency.

📖 Want to see RFID in action?

Discover how SNCF and Cepovett deployed Primo1D’s RFID yarn in 40,000 uniforms to streamline laundry operations, reduce losses, and support sustainable garment lifecycles.Read the full use case here and learn how embedded RFID is reshaping uniform management at scale.

Key Benefits with Primo1D RFID

Real‑Time Lifecycle Tracking

Bulk‑scan uniforms at each stage—laundry, issue, wear, repair, recycling—cutting what once took hours down to seconds.Smart Locker Integration & Stock Efficiency

Embedded tags adapt seamlessly to automated lockers, enabling dynamic uniform assignment and reducing idle inventory and overproduction.Circular Economy & End‑of‑Life Recycling

Durable RFID tags preserve critical lifecycle data through till recycling, supporting smarter fiber recovery, sustainability reporting, and regulatory compliance.Operational Excellence

A smarter uniform system reduces losses, cuts labor costs, and enhances service levels—all while supporting ESG targets.

About Primo1D

Primo1D is driving a technological revolution by embedding intelligence into textiles. Their passive RAIN RFID tags—woven into yarn segments from 6 to 14 cm or integrated as strips/tubes—offer robust, invisible, and sustainable identification for uniform lifecycle management. Crafted to endure harsh industrial conditions, these tags support everything from inventory optimization to circular‑economy objectives.

Whether you manage hospital scrubs, hotel uniforms, or industrial protective wear, Primo1D’s embedded RFID empowers you to:

Monitor garment lifecycle performance in real time

Automate bulk scanning and handling

Reduce inventory loss and excess stock

Support garment reuse and recycling

Cut operational costs and elevate service quality

🎥 Watch the full video series here and explore how Primo1D’s embedded RFID technology is transforming uniform logistics from the inside out.

Are you managing thousands of garments across multiple locations or teams? Are losses, inefficiencies, or sustainability goals driving your need for smarter solutions? Let’s talk.

Primo1D helps you make every garment traceable, every process smarter, and every uniform investment last longer. Our team is ready to assist you with tailored RFID integration strategies—from pilot phase to full-scale deployment.