From Tag to System: How Identiv Manufactures Complex IoT Devices at Scale

Why simple tags aren’t simple anymore

As IoT systems mature, labels, inlays, and tags are being asked to do far more than identify an item. Increasingly, they’re expected to sense temperature, humidity, shock, light exposure, or changing environmental conditions and to deliver that data accurately and repeatedly over long lifetimes.

The result is a quiet but profound shift: many “tags” are no longer single-function components. They’re compact electronic systems built on flexible substrates.

Multicomponent manufacturing is the new bottleneck

This evolution creates a new bottleneck and a new advantage. The breakthrough isn’t only in better sensors or smarter chips, but in whether these multicomponent devices can be manufactured reliably at industrial volumes, with stable yields and predictable cost. That manufacturing reality is shaping the next phase of IoT adoption: multicomponent manufacturing (MCM).

In the early days of RFID, manufacturing was defined by elegant simplicity. A chip was bonded to an antenna, and production lines ran at extraordinary speed. But as applications expanded into healthcare, logistics, authentication, and condition monitoring, requirements became less forgiving.

Designs started incorporating stabilizing passive components, precision timing elements, sensors, and power sources. Each addition increased capability, and it raised the bar for process control.

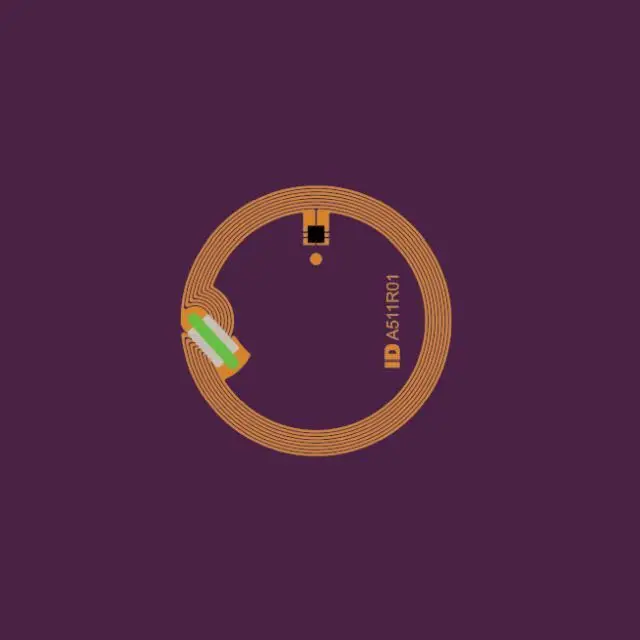

ID-Garment-A511-424DNA

The ID-Garment-A511-424DNA offers secure, durable, and washable NFC technology for apparel authentication and traceability.

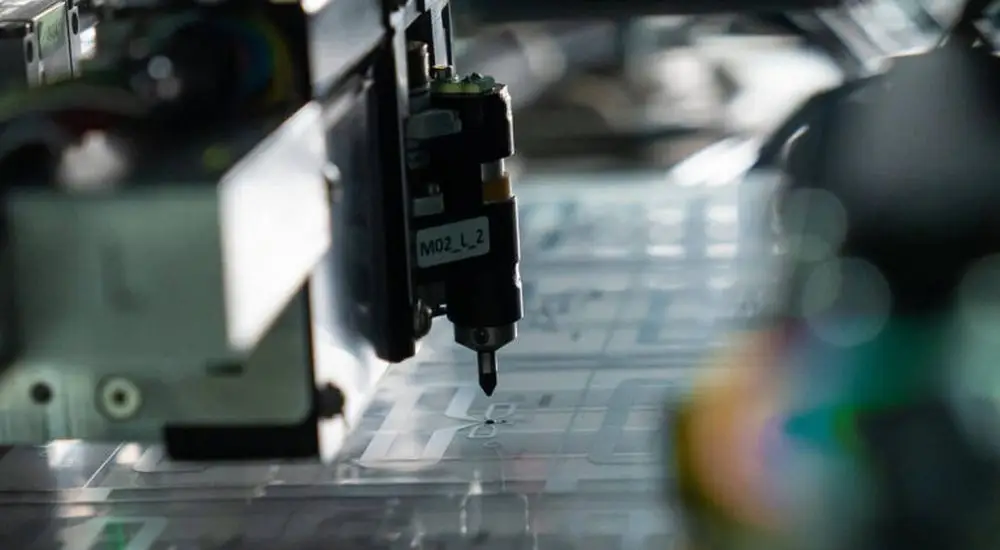

What multicomponent really means on the factory floor

When you add components, you don’t just add steps. You add interaction. A change in battery chemistry can affect lamination and curing behavior. A new sensor can shift antenna geometry and test thresholds. Throughput targets tighten placement tolerances and demand sharper defect classification.

In multicomponent manufacturing, design and production are inseparable: every decision propagates across the line.

Identiv’s head start: a decade built in production

Identiv began building multicomponent manufacturing capabilities more than a decade ago, when early customer programs exceeded what conventional single-component assembly could support. At the time, dedicated roll-to-roll multicomponent lines weren’t yet the industry norm.

Identiv’s engineering teams adapted equipment, developed multi-pass workflows, and refined process parameters to introduce additional components without sacrificing consistency.

That early work expanded across consumer electronics, brand authentication, BLE devices, and multi-sensor tags. Over time, repeated programs reinforced the same discipline: translating advanced architectures into repeatable, scalable production. Tens of millions of multicomponent devices later, Identiv has developed deep, practical experience navigating the tradeoffs that determine success, from throughput versus tolerance to durability versus thickness.

Thailand: manufacturing infrastructure designed for advanced MCM at scale

Identiv’s Thailand manufacturing facility concentrates this expertise into a highly optimized hub for advanced RFID and BLE manufacturing, including high-complexity multicomponent assemblies. Following a multi-year transition, the site combines modern multicomponent equipment with embedded process knowledge across engineering, quality, and operations.

Equipment configuration, parameter tuning, in-line quality control, and reliability testing are integrated end to end to support high-mix, high-value products at scale, even as component counts rise and durability requirements tighten.

Manufacturing is now the enabler of trusted IoT data

As IoT devices become long-lived sensing systems, manufacturing precision increasingly determines what data can be trusted upstream. Reliability is established on the production line long before software ever sees a signal.

Multicomponent manufacturing may operate behind the scenes, but it sets the practical boundaries of what connected systems can achieve in the real world, where advanced requirements must still meet cost thresholds and supply chain realities.

That’s why Identiv’s early investment in MCM, and its continued leadership through production experience, matters now. The future of specialized IoT won’t be defined only by what can be designed, but by what can be built repeatedly, across millions of units.

About Identiv

Identiv delivers specialized IoT solutions, including RFID and BLE inlays, tags, and transponders, enabling secure identification and connected experiences across industries. Get in contact!