- UCODE RAIN RFID tags enable continuous inventory monitoring and improved expiration date handling in the food supply chain.

- The technology reduces food waste by supporting dynamic pricing and efficient stock rotation methods like First In First Out (FiFo).

- UCODE tags improve supply chain visibility and help prevent food fraud through unique digital product identities.

- Extended EPC memory in UCODE 9xe chips allows storing critical attributes directly on the tag, facilitating faster data processing and compliance with traceability standards.

The food supply chain is a complex and multifaceted system that spans from farmers to consumers. Numerous challenges can arise during a product’s journey, including lack of product traceability, food safety, and inventory management. One solution to these challenges is the use of UCODE based tags from NXP Semiconductors.

These tags enable real-time visibility of products as they move through the supply chain, allowing for better inventory tracking, enhanced supply chain efficiency, and improved food safety.

By tagging food items with UCODE based tags, suppliers can monitor location and store important information (lot number, expiry date), ensuring that products remain safe and fresh until the point of sale. Skyrocketing food prices and sustainability concerns move increasing numbers of brands and retailers to adopt RAIN RFID solutions.

Food Industry

Quick service restaurants

Quick service restaurants (QSRs) operate in a fast-paced environment, where speed and accuracy are essential to their operations. UCODE can help QSRs to improve their operations in a number of ways. Tags with UCODE products can be used to track inventory levels, allowing restaurant staff to quickly and easily identify when supplies are running low and need to be reordered.

In addition, UCODE enables efficient ways of expiration date management in a way that the QSR uses products with the shortest expiration dates first. This ensures that the restaurant always has the ingredients and supplies it needs to serve customers efficiently, while reducing waste.

Food retail

By tagging products with UCODE product based labels, retailers can easily track inventory levels, monitor expiration dates, and identify products that are approaching their sell-by date.

This enables them to make informed decisions about when to restock products, respectively which products should be put on sale.

Convenience & unmanned stores

UCODE can be used to improve the accuracy and speed of the checkout process.

By tagging products with UCODE product based tags, retailers can quickly and accurately scan products at the checkout, reducing the likelihood of errors and improving customer satisfaction.

Extremely fast and convenient self-checkout with UCODE occurs at unmanned stores or RFID-based kiosks. Multiple item checkouts are the baseline there. Items can stay in the shopping bag during checkout, and customers enjoy a fast and convenient shopping experience whenever it suits them.

Benefits of UCODE

Constant monitoring of inventory and usage trends

NO overstocking / waste

Faster reaction of the supply chain to instant meal trends

Strong reduction of “meal currently not available”

Improved expiration date management – First In/First Out

Store employees with more time to serve customers

Inventory data accuracy increases

Sales increases

Pain Points

Efficient processes

Food supply chains are in a process of acceleration. Productivity is increasing, volumes are becoming larger while the workforce is reducing in the food supply chain operations. The resilience of regional and local supply chains is put under strain and requires higher levels of automation at the transport and asset level. The insights required for effective forecasting and replenishment plans can be generated by RFID. Barcode or video based systems require line of sight are are therefore not suitable to automation at scale.

On-time delivery

Visibility into the expected time of arrival has become commonplace for players within the supply chain. For optimized forecasting and replenishment plans it is a must-have. Since the 1970s, Back-of-House (BoH) space has been reduced in the food industry. Order volume has decreased while the order frequency has increased.

Food retailers now rely on Just-in-Time (JIT) delivery several times a week. The current system is “near stockless” which requires extensive planning and visibility into accurate inventory status for replenishment orders. The short lead times and fast-moving supply chain require very careful data-driven forecasting and planning.

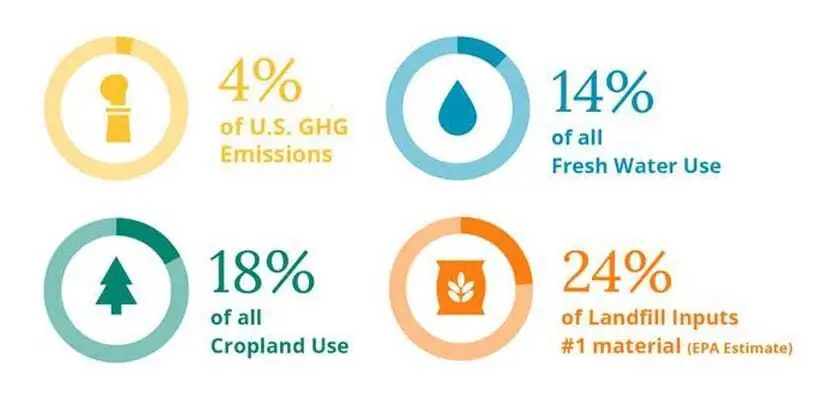

Food waste

Thirty percent of the food that is produced annually is thrown out. Concerns about food waste are rising.

Technology can help as when the expiry date is saved on the chip, employees can scan the items to find out the products with near expiry date and apply dynamic pricing to ensure these products are sold before the others. The need to throw away batches will not arise with an improved expiry date management.

Visibility into the product journey

The challenges of recent years have provided an ideal climate for food fraud. The FDA estimates that food fraud in the U.S. represents 40 billion USD in annual losses. In the EU, the damage is 8 to 12 billion Euros annually. The most common types of fraud are brand representations, protected geographical indications or protected designations of origin.

The most common form of food fraud in the EU is the mislabeling of organic food. UCODE can help prevent mislabeling and brand fraud. UCODE products-based tags on goods enable unique identification of a product's place of origin. They also ensure traceability of the goods, so that the correct information is provided at the point of sale about the origin, growing conditions (for organic products) and transportation and delivery journey.

Ensuring Product Quality

Fresh Food is Demanding

Hardly any other area in logistics places such high demands on quality standards as food logistics in the fruit and vegetable sector. However, poor communication with suppliers or interruptions in the supply chains make it difficult to guarantee high quality throughout.

This is why UCODE is so important in the food industry as it can help with real-time information for ensuring the quality of consumables. Customers weigh good quality against low prices when making purchasing decisions.

Quality = Freshness

The shelf life of freshly purchased fruits and vegetables depends heavily on the quality of the produce at the time of purchase. With an unbroken cold chain and speedy transport from the place of harvest to the point of sale, the shelf life is shortened.

The temperature- controlled food supply chain is large and requires more complex movements, usually characterized by faster supply chains, as few touchpoints as possible, and different types of vehicles for transportation. Failure to maintain the cold chain causes 13 percent of food waste each year.

For 36 percent of consumers, long shelf life actually plays a decisive role in their purchasing decision. Criteria for purchase exclusion are overripeness (52 percent), bruises (50 percent) and dents (31 percent). Positioning older products in the warehouse in such a way that they are more likely to be sold is quickly achieved with RAIN RFID tagged units and a modern merchandise management system.

In the warehouse, if the products in the same category are stored according to their shelf life, inventory management strategies like "First expired, First out (FeFo)" and "First in, First out (FiFo)" can be easily put into place.

Track & Trace Technologies

Standards for visibility

Food supply chains have various parties involved, and cooperation from trading partners can speed up the adoption of technologies to ensure efficiencies. However, there are regulations for traceability standards. Adoption of RAIN RFID technology with GS1 as a guiding standard can enable compliance to the traceability regulations while ensuring supply chain visibility.

A World Where Every Item Has Its Own Digital Identity

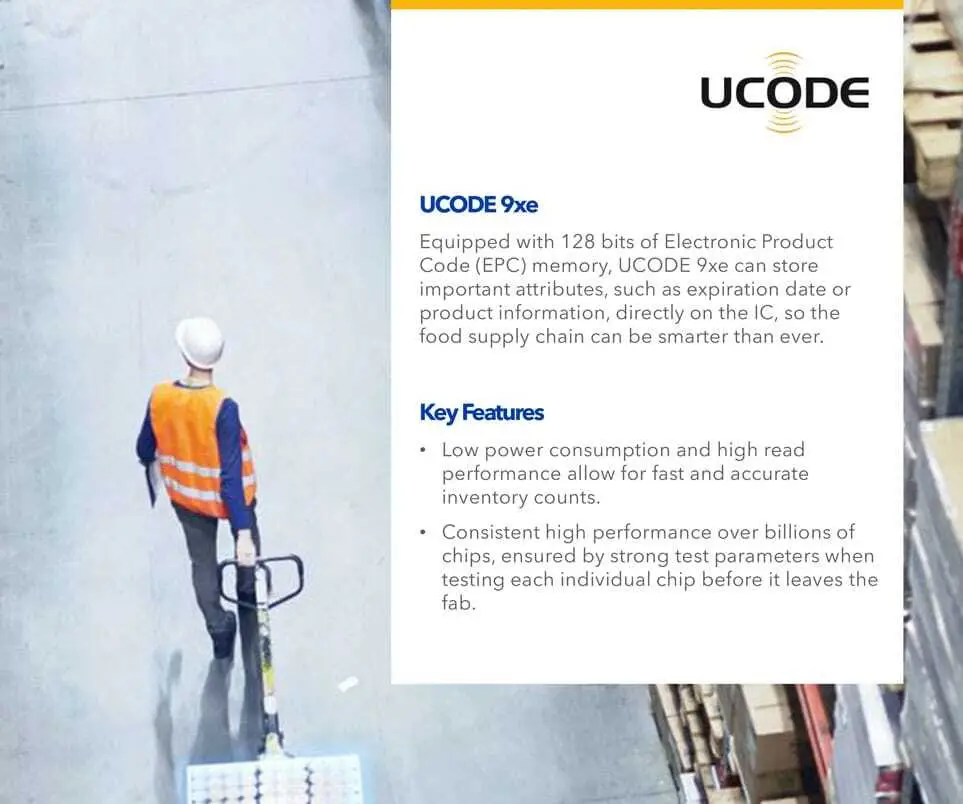

The UCODE 9xe is a high-performance RAIN RFID chip offering extended EPC memory that allows storing important attributes like expiration date or production information directly on the IC, so IoT applications can be even smarter. The Scope of UCODE 9xe

Designed as a drop-in replacement for the high performance UCODE 9, the UCODE 9xe offers the same feature set and RF performance as UCODE 9, but with 128 bits of EPC memory it supports a wider range of IoT use cases.

The result is a RAIN RFID tag that benefits brand owners, retailers, and consumers alike. This product is a great fit for the food market as it is launched specifically having these applications in mind:

Perishable-food tracking to ensure freshness

Real-time, point-to-point tracking of any product within the supply chain

Omnichannel retail support with precise tracking from source to store

High-speed store checkouts for increased customer satisfaction

Extended EPC memory

UCODE 9xe requires no line of sight for reading the items and can read thousands of items within seconds. These features make the RAIN RFID technology a good choice for supply chain and inventory management applications.

With the extended EPC memory, UCODE 9xe stores retail/supply chain attributes directly on the chip that saves time and increases tag encoding throughput.

"By utilizing the extended EPC memory of the UCODE 9xe, essential attributes can be stored directly on the IC, resulting in an optimized and streamlined supply chain."

Ralf Kodritsch - Director Global Segment Manager RFID Solutions