- E-Thread embeds RFID directly into textile yarn for invisible, durable product identification.

- The RFID yarn withstands up to 200 industrial washes and resists heat and chemicals.

- Integration enables faster inventory processes and reduces errors such as mixed sizes.

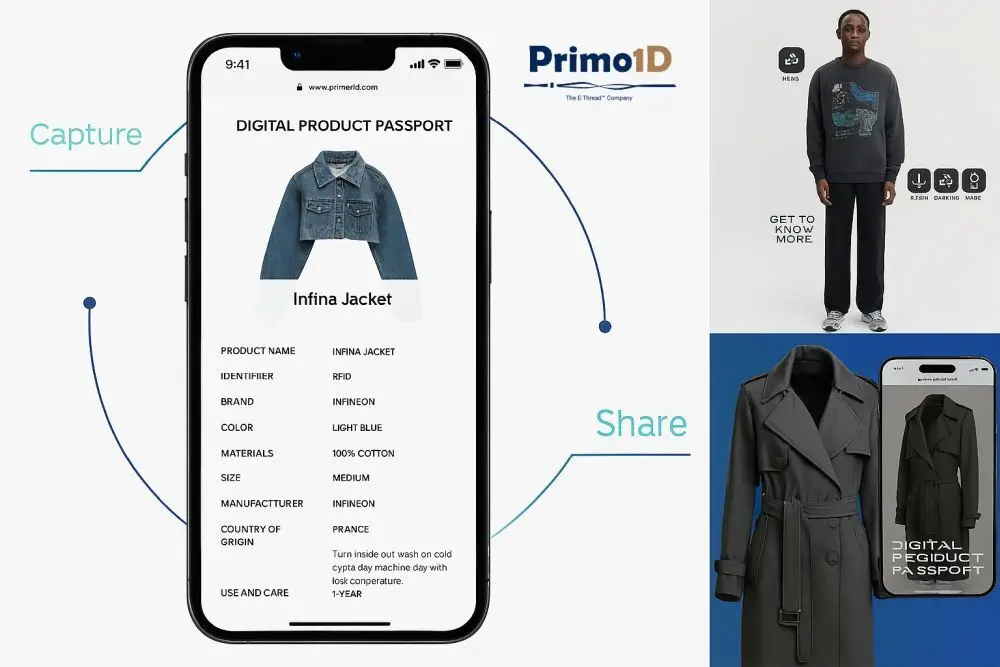

- The technology supports digital product passports to facilitate repair, reuse, and recycling.

- Real-world use cases demonstrate an 87% reduction in inventory processing time with E-Thread.

The integration of RFID into ERP systems is transforming the textile and clothing industry. This is demonstrated by the customer example "The Compass" from northern Portugal.

Three perspectives, one goal: making textiles intelligent. In this interview, Nuno Lopes, RFID expert at Portuguese automation specialist Accurex, Carlos Miguel Gonçalves, co-owner of MacWin-Tek, ERP/software for the apparel industry, and Valériane Henry from Primo1D discuss how E-Thread, a UHF RFID tag integrated into yarn—makes inventories more accurate, processes faster, and products recyclable.

Practical experience from Portugal, technology from France

Two voices from Portugal represent the areas of manufacturing and IT. Nuno Lopes represents the perspective of automation and system integration and shows how RFID is used in production lines, warehouses, and quality assurance.

Carlos Miguel Gonçalves complements MacWin-Tek's ERP/WMS perspective, explaining master data, serial numbers, goods receipt, inventory, and analytics.

As a technology provider, Valériane Henry from Primo1D explains how integrated RFID yarn works, what typical installation points are used in the product, and what impact this has on life cycle, service, and recycling.

E-Thread: Invisible identity, robust suitability for industrial use

"With E-Thread from Primo1D, product identity can be embedded directly into the textile – invisibly and tamper-proof," explains Valériane Henry.

Depending on the design, the tag is designed for up to 100 to 200 industrial washes, remains permanently attached to the product, and provides the data basis that simplifies repair and recycling. The technology withstands washing, heat, dyeing chemicals, and mechanical stress, can withstand temperatures of up to approximately 200 °C, and achieves reading ranges of up to approximately 12 meters, depending on the environment and antennas.

Technologically, E-Thread is protected by 30 international patents. Each day, it is assembled, coated, and integrated at the factory in the Auvergne-Rhône-Alpes region using textile pre-products from partner weaving mills in the same region.

What is Primo1D's RFID yarn?

Primo1D's RFID yarn is not a "stuck-on" transponder in a new form, but a genuine textile carrier in which a UHF/RAIN RFID module is technically embedded in such a way that it can be processed like normal yarn.

The system essentially consists of a microchip (EPC Gen2/ISO 18000-63-compatible) and a very slim antenna structure made of conductive material. This assembly is encapsulated using micromechanical technology and integrated into a thread-like composite material.

The result: a thin, flexible "yarn section" that can be invisibly and tamper-proof inserted into seams, edges, bindings, or even woven/knitted structures.

The RF design is optimized for the UHF band (approx. 860–960 MHz). Since the thread has to cope with very different environments in real textiles (cotton, synthetics, moisture, proximity to the body, metal parts), the antenna is designed to compensate for detuning as robustly as possible. In practice, this enables a reading range of several meters to double-digit distances.

On the data/security side, the yarn functions like a standard UHF tag: it carries an EPC serial ID ( plus TID), optional user memory, and supports the standard's protection mechanisms, such as access/kill passwords or lock states. This allows data protection requirements (e.g., for luxury items) to be met without losing the functionality for returns, warranty, or the Digital Product Passport (DPP) .

The product data itself is not stored on the thread, but in the backend – the EPC serves as a stable product ID/pointer throughout the entire life cycle.

Mechanical and chemical resistance is a key difference from labels or sewn-in inlays. Embedded in a textile composite and encapsulated, the thread often withstands more than 100 household washes, heat (processing and ironing temperatures, sometimes far above this in industrial cycles), and chemical stresses (e.g., dyeing, washing lye).

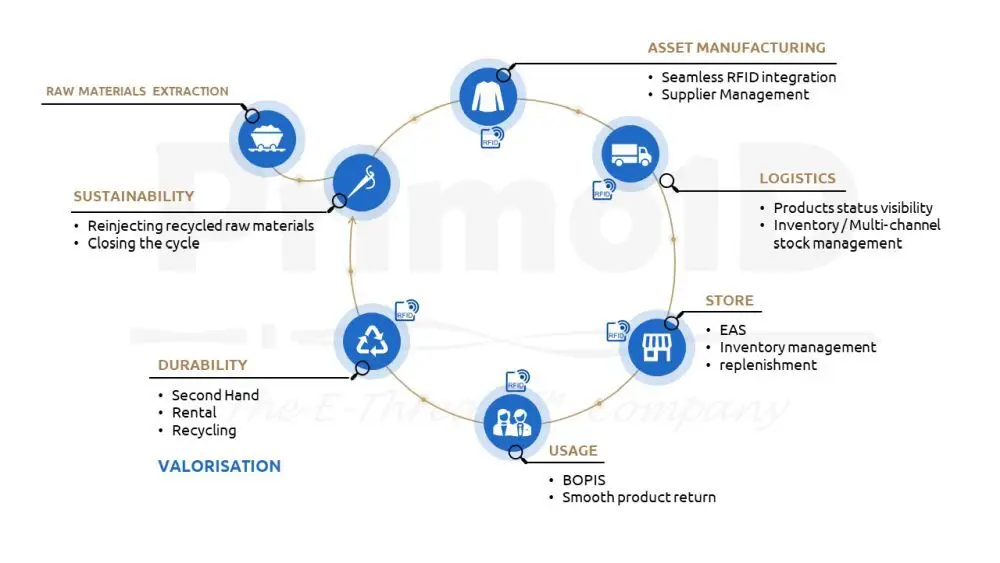

Since the identity is assigned early in the manufacturing process, often before cutting and assembly, it accompanies the product through all process steps: manufacturing, further processing by third parties, goods issue, goods receipt, warehouse, store, service, resale, and recycling.

Innovative textile technology

From a technological perspective, E-Thread combines HF design, microelectronics, and textile technology in a single, processable component.

The result is a permanent, serial product identity that is invisibly embedded in the goods, logistical efficiency (counting, inventory, circulation control), protective functions (anti-counterfeiting/EAS coupling), and recyclability (DPP readiness, repair, reuse, sorting) – without compromising the design and wearability of the textile.

Principle and unique selling points

Unlike labels, hang tags, or sewn-on transponders, E-Thread is fully integrated into the textile—for example, in seams and edges—and is given a serial identity at the start of production.

The technology is process-stable: it withstands washing, heat, dyeing chemicals, and mechanical stress, can withstand temperatures of up to approx. 200 °C, and, depending on the environment and antennas, achieves reading ranges of up to approx. 12 m. It thus creates an early, permanent identity as the basis for DPP scenarios, service, and resale.

Industries and areas of application

In the fashion and sports sectors, E-Thread increases inventory accuracy, reduces shrinkage, and enables counterfeit protection; luxury brands appreciate the invisible, tamper-proof labeling. For workwear and PPE, often in leasing and rental models, the yarn enables robust lifecycle tracking of wash cycles, inspection intervals, issuance, and return, as well as transparent cost allocation per use.

Hospitals and clinics use it for robust laundry tracking to reduce shrinkage and verify the hygiene chain. Hotels, cruise lines, and caterers use E-Thread to manage their linen and towel cycles in real time and accurately verify invoices. In industry, technical textiles such as lifting slings, nets, ropes, filters, airbags, interior textiles, and composites are opening up new scenarios for traceability and liability protection.

For footwear and outdoor equipment, serial and size tracking, warranties, and rental/test pools are supported. In logistics and fulfillment, E-Thread speeds up goods receipt, reduces packaging errors, and enables fast cycle counts without visual contact.

Throughout the cycle, unique identification facilitates automatic item recognition, fulfillment of DPP obligations, and improved sorting quality and speed.

Customer example: "The Compass" from northern Portugal

This real-world use case shows the end-to-end chain from raw material to store: EPC coding begins at the start of production. The serial identity accompanies cutting and assembly as well as goods issue at the manufacturer.

The brand checks the incoming goods within minutes via RFID, automatically books them in the WMS/ERP, distributes them to the central warehouse and stores, and ensures complete traceability. Typical errors, such as mixed-up sizes, can be avoided because the identity is already embedded in the fabric.

Amazing effects

The effects are measurable for large batches: the effort per 1,000 pieces drops from around 40 to 5 minutes – a time saving of around 87 percent. The program started with 500,000 tags in a gradual rollout; within one semester, around 50 percent of these were in productive use. The goal is five million tags. The manufacturer supplies several brands, so Primo1D expects increasing interest from other brands.

Greater process reliability from the very first step

For textile manufacturers, an RFID thread integrated into the yarn offers above all security and speed from the start of production. Since the series identity is already embedded in the raw textile, cutting, assembly, and work steps at suppliers can be seamlessly checked. Mixed-up sizes, incorrect assignments, or missing parts are immediately noticeable – this reduces waste, rework, and complaints.

Goods are issued and accepted via RFID in a matter of minutes instead of hours; large batches no longer need to be counted manually. Stocks are visible in near real time, cycle counts run in the background – the flow of goods becomes noticeably faster and more stable.

Traceability

The continuous serial number creates a consistent supply chain – from raw materials to third-party refiners to handover to the brand. Recalls can be limited to specific batches and series, packaging errors and shrinkage are measurably reduced, and billing with brands and logistics partners becomes cleaner.

Technology, data, and data protection

The coding process begins at the start of production: orders (e.g., "300 T-shirts, size M") are visible in the software, EPCs are generated and assigned to the integrated tags before insertion. The tag contains a technical identifier by default – specifically the Electronic Product Code (EPC) and the chip TID; optional user memory fields are only used when needed.

Personal data is not stored on the tag; the personal reference is created exclusively in the backend when a company links the product ID to customer data. Transparency and consent are part of the communication about the product (note/label/FAQ). Protective functions such as Kill or Lock in accordance with EPC Gen2/ISO 18000-63 enable deactivation or access restriction via password.

In luxury scenarios, Privacy Lock is often used to maintain functions such as warranty/returns and prevent unauthorized readings.

Statement on the DPP: keep active instead of deactivating

With EPC as a stable product ID, E-Thread is fundamentally DPP-compatible. With RFID yarn, manufacturers meet the requirements for the future digital product passport without having to re-label at the end.

DPP information (materials, repairs, sustainability data) is provided in the backend or via GS1 Digital Link/EPCIS. Since textiles will be regulated later than batteries and electrical appliances, the schedule is staggered. Regardless, the tag should not be deactivated : it must remain readable offline for repairs, reuse, and recycling; permanent deactivation would undermine important circular functions.

Environment and recycling

Tests have shown that at least 100 standard household washes are possible. Often, the fabric wears out faster than the yarn. Actual durability depends on the specific manufacturing process, for example, whether the chip is integrated before dyeing or printing and which chemicals and temperatures are used.

The eco-profile is favorable: the LCA value for the label is around 9 g CO₂e. Compared to around 9 kg CO₂e for a T-shirt, this proportion is negligible. In projects, including one with Decathlon, T-shirts with embedded e-thread were processed into recycled yarn; the metallic mass of the label did not interfere with the process. At the same time, improvements in eco-design are being integrated.

The goal is to use as little material as possible while ensuring high performance and durability.

Economic efficiency

Many brands work with multiple production partners in Portugal, North Africa, or Spain. When one manufacturer demonstrates the benefits of RFID, this is often extended to other partners. Who bears the costs varies: today, it is often the manufacturer—especially in the premium/luxury sector, where efficiency gains are immediately visible.

As maturity increases, brands are increasingly supplying manufacturers with pre-made tags, similar to traditional labels. For very low-cost items, integration remains a question of economic viability. Key factors are process gains (goods receipt, inventory, error rates, shrinkage) and the ability to meet legal requirements such as the DPP.

The partners in profile

About Primo1D

Primo1D was founded in Grenoble in 2013 as a spin-off of the CEA-Leti research institute . The company has industrialized the E-Thread technology developed there.

About Macwin

MacWin focuses on the development of specific ERP (enterprise resource planning) software solutions and the provision of high-quality, specialized IT services. The company originated and grew in the textile and clothing industry (ITV). Since 1998, ITV has been the core area of its business activities. MacWin has the strongest presence in this segment in terms of both the size and number of projects implemented and the diversity of solutions offered.

A central component of the solution is the integration of RFID into the ERP system along the entire ITV production process. This project is part of TEXP@CT, which is funded by the European Union/NextGeneration EU, and is currently being implemented exclusively through the use of E-Thread.

About Accurex

Accurex specializes in RFID technologies and offers a broad portfolio of tags, readers, antennas, and printers for LF, HF/NFC, and UHF. In addition to hardware, the company develops customized, turnkey RFID solutions, alone or with system integrators, for automation, improved traceability, and greater process efficiency.

One focus is on the apparel and textile industry: Accurex supports retailers, manufacturers, uniform managers, and industrial laundries with solutions for item-level tracking, accurate inventory counts, reduced shrinkage, and optimized logistics. Robust tags and reader systems are also used in logistics and industrial environments.

Accurex not only supplies technology, but also supports projects from planning to implementation – with a focus on seamlessly integrated RFID systems that create measurable business value.