- Neosid is a global market leader in injection-molded soft ferrite components and miniature HF RFID transponders.

- Ferrite cores concentrate magnetic fields, enabling RFID transponders to work reliably in direct contact with metal.

- Complete in-house production and injection molding allow precise, complex geometries and customer-specific miniaturized designs.

- Patented housing geometries prevent mechanical stress on pressure-sensitive ferrite cores and secure transponders under vibration and temperature variation.

- Simulation-led feasibility studies accelerate development and reduce risk for demanding industrial applications.

From ferrite pioneer to global market leader for specialized RFID solutions

For decades, the German company Neosid has been the global market leader in the injection molding of soft magnetic ferrites.

Today, Neosid focuses on passive RFID transponders. Its main areas of activity also include the manufacture of inductive components and customer-specific sensor coils. The company's ferrite know-how and expertise in winding inductive components flows directly into the development of transponders.

Neosid develops solutions for customer-specific requests with passive RFID transponders, for example in the form of plugs or inlays.

The roots of ferrite expertise

Almost 100 years ago, Neosid in Berlin was one of the first European companies to use ferrite material developed in Japan to manufacture magnetic components for high-frequency technology. These ferrites paved the way for compact and powerful components for radios, coil technology, and wireless communication.

In 2010, Neosid made the leap into the world of RFID with the development of the first miniature RFID transponders with ferrite cores. This made it possible for the first time to create reliable RFID solutions that can be used directly in metal.

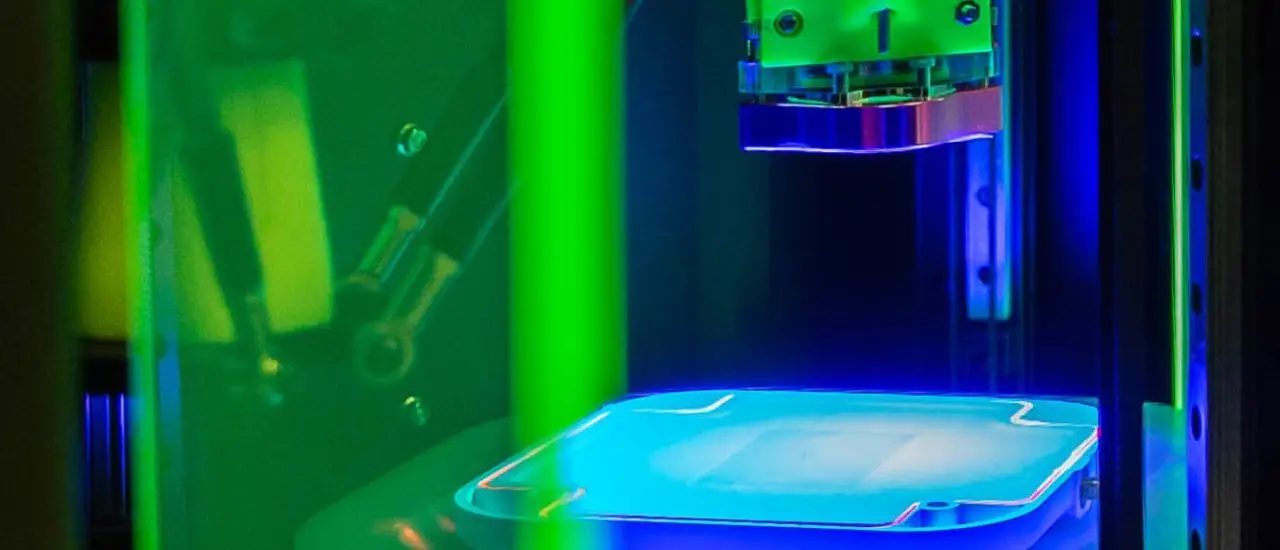

Ferrite forms the heart of the miniature transponders, which work reliably even in demanding metal environments. Everything is produced in-house, from the ferrite compound for the core to the winding, encapsulation, and housing, right through to the final testing of the finished RFID transponder. The high level of vertical integration and complete control over materials, form factor, and production enable even highly complex special solutions.

The result is high-precision, miniaturized RFID solutions for industry, construction, medicine, logistics, and automotive.

Incidentally, the name Neosid is derived from the Latin "Neos Sideros" and means "new iron" – a clear reference to the company's origins in the development and processing of soft magnetic ferrites.

What is ferrite – and why is it crucial for HF RFID?

Ferrite is a ceramic, soft magnetic material consisting of iron oxide (Fe₂O₃) and other metal oxides, such as zinc, manganese, or nickel oxide. A special sintering process produces a high-density material whose magnetic properties can be precisely adjusted.

In electrical engineering, ferrite is used to concentrate and control magnetic fields. Ferrite is indispensable, particularly in high-frequency applications such as RFID, antenna technology, and transformers, as it reduces energy losses, increases efficiency, and enables miniaturized, high-performance components.

Ferrite is crucial for RFID transponders that operate directly on or in metal. It acts as a magnetic concentrator that focuses the magnetic field lines, ensuring stable communication between the transponder and the reader. Without ferrite, many modern solutions in the fields of industry, logistics, medical technology, and automotive would not be possible.

Ferrite is therefore the key material for reliable and compact RFID high-frequency technologies. The following table shows the change in the resonance frequency of the tag in different metals.

Material | Chemical | Pre-tuning of the | resonance frequency | Operating frequencyfB |

|---|---|---|---|---|

Aluminum | Al | -2.0 MHz | 11.6 MHz | 13.60 MHz |

Iron | Fe | -1.0 MHz | 12.6 MHz | 13.60 MHz |

Brass | CuZn | -1.5 MHz | 12.1 MHz | 13.60 MHz |

Stainless steel | e.g. X2CrNi12 | -500 kHz | 13.1 MHz | 13.60 MHz |

Interview

Interview with Matthias Höß, Head of Development and Project Management at Neosid.

What makes Neosid the global market leader for miniature RFID transponders with ferrite cores?

Matthias Höß: That's right. Neosid is the global market leader because the company can manufacture ferrite components using injection molding—a rarity in the industry. This results in precise and complex geometries that are otherwise only found in plastic components. Our specialty is challenging geometries and form factors. In terms of design, we are the clear global market leader in both the breadth and depth of our manufacturing capabilities.

Other suppliers cover this area at best in small niches or as a by-product.

For us, on the other hand, the focus is on a holistic solution that has been specifically developed to meet even the complex special requirements of our customers.

How are customized geometries created?

Matthias Höß: It's all about the application. In this context, shaping means much more than just the outer shell. The size, shape, material combination, and even the inner workings of the RFID transponder are precisely tailored to the respective application. This results in components that deliver maximum performance even under extreme conditions.

The design not only influences the mechanical fit, but also the performance of the transponder, such as its range, readability, and reliability. It is therefore the key to being able to offer customer-specific special solutions.

In concrete terms, this means that a customer comes to us with a specific requirement, such as a certain size, a defined volume, or special dimensions. On this basis, we develop a customized shape into which the ferrite core and all other components are later precisely integrated. The result is an RFID transponder that is tailored exactly to the respective application.

What are these special requirements?

Matthias Höß: One example is a miniaturized RFID transponder that is manufactured so precisely that it fits exactly into the drill hole of a surgical instrument. Or a transponder that is integrated into a particularly robust housing to withstand strong vibrations and extreme temperatures in a tunnel boring machine.

Individual geometries are also possible, which are specially developed to enable fully automated assembly by robots – for maximum efficiency and precision in production. Another example is a current project in the port industry, where our transponders are used not on containers but on cranes, hooks, and eyelets—components that are exposed to impacts, falls, and strong vibrations on a daily basis.

Even under these extreme conditions, the transponders work reliably for years without failure.

How do you prevent the RFID transponders from coming loose due to vibrations and temperature fluctuations?

Matthias Höß: One of our approximately 20 patents relates to the plastic housing of the transponder. Background: Transponders can come loose and get lost due to temperature fluctuations and strong vibrations. Our solution is a specially developed housing geometry that interlocks with the drill hole when pressed in. This ensures that the transponder remains securely in place even under harsh conditions.

Important to note: Ferrite is pressure-sensitive. The geometry is therefore designed so that clamping and vibration forces are absorbed by the plastic housing and not transferred to the ferrite core. The result: maximum durability and frequency stability despite temperature changes and vibrations.

How complex is the development of special solutions?

Matthias Höß: We use simulations as an important supporting measure. Right from the start, we can offer our customers a feasibility study in which we clarify whether a transponder in the desired size and for the intended environment can be technically implemented or whether an alternative solution should be developed. This simulation provides early development certainty and saves time and costs before the actual product development begins.