- Battery-powered ultrasonic sensors provide continuous level data for 1,000‑liter lubricant drums.

- LoRaWAN transmission eliminates cabling and enables quick, low-cost deployment with a small gateway.

- Real-time data creates alarm thresholds, transparent consumption histories, and data-based reorder points.

- The solution supports scalable retrofitting and future API integration with ERP or MES systems.

baier & michels is working with Pepperl+Fuchs to professionalize lubricant level monitoring: Instead of manual rounds, digital tank monitoring with ultrasonic level sensors (WILSEN.sonic.level IBC) and LoRaWAN provides continuous data from 1,000-liter drums. Consumption and remaining ranges become transparent, limit values trigger alarms in good time, and the reorder point can be determined on the basis of data.

The result: greater safety, predictable procurement, and a scalable setup from quick retrofitting to clean connection to databases and dashboards.

Supplier to the automotive industry, agricultural technology, and mechanical engineering

With 500 employees at seven locations worldwide, the baier & michels Group (b&m) supports the manufacturing industry with connection technology solutions. Cold-formed parts such as direct screw connection systems form the basis of its products. Its customers include OEMs and suppliers, primarily from the automotive, agricultural technology, and mechanical engineering sectors.

b&m also supports its customers with connection tests in its in-house laboratories, application technology consulting, and product development. b&m has been part of the Würth Group since 1973.

From trial operation to bottleneck risk

Around ten years ago, b&m started with a small trial production facility – just five machines were in operation at the time. The demand for lubricants was manageable, the barrels seemed to last forever, and there were no bottlenecks.

However, with the rapid growth of recent years, the situation has changed fundamentally. Today, 40 machines are already in use, with another ten systems on the way.

With each new machine, not only does production output increase, but so does the consumption of lubricants and cooling lubricants – and with it the risk that a particular oil will suddenly become critically scarce at the very moment it is needed. A total of seven to eight different lubricants are used – from machine oils for component lubrication to specialized cooling oils, which vary depending on the type of machine and application.

"With the growth of b&m and the increasing complexity of our processes, manual control of fill levels has become significantly more time-consuming – especially due to the shortened inspection intervals. A digital solution provides noticeable relief here and ensures greater transparency and efficiency in the ordering process," explains Maximilian Korte, software developer at baier & michels.

The challenge

Every oil has a completely different consumption rate. Some oils last for a long time, while others need to be refilled very quickly. To avoid bottlenecks, certain lubricants are even kept in stock as a precaution. Depending on the type of oil, a remaining stock can last for a long time – or be used up within a very short time.

Starting point: Manual level control

Oil consumption in the company is relatively constant during normal operation. However, there are always situations in which significantly more oil is suddenly needed – for example, when oil sticks to screws, when defects occur, or when new machines are put into operation.

For example, when oil sticks to screws, when defects occur, or when new machines are put into operation. In such moments, unplanned withdrawals regularly occurred that were not noticed in time.

Until now, the entire control process was completely manual: several times a week, an employee from the production office had to walk through the production facility to check each tank individually. Instead of modern sensor technology, mechanical dial gauges were used – a float on a rope indicates the fill level, similar to an old fuel gauge in a car.

Until now, it was the responsibility of the production department to report when a tank was almost empty. This meant additional coordination effort – especially during stressful periods or shift changes. Delayed reports or lack of time occasionally meant that replenishment had to be organized at short notice – a process that was not only expensive but also involved considerable organizational effort.

The challenge is made even more complex by the large number of lubricants. Seven to eight different lubricants are used in parallel – from classic machine oils for different types of machines to specialized cooling oils.

The values determined were carefully documented by hand and then evaluated. This procedure was very time-consuming and only provided selective information – but not a complete consumption history.

"Without the data, it was almost impossible to determine the optimal time to reorder. Much depended on the experience of individual employees. If that person was unavailable, it could quickly lead to unnecessary additional organizational effort," explains Maximilian Korte, software developer at baier & michels.

With the growing machine park—currently 40 machines, soon to be 50—this manual system became increasingly time-consuming. It was clear that a digital, automated solution was needed to create transparency, avoid errors, and make the management of operating materials future-proof.

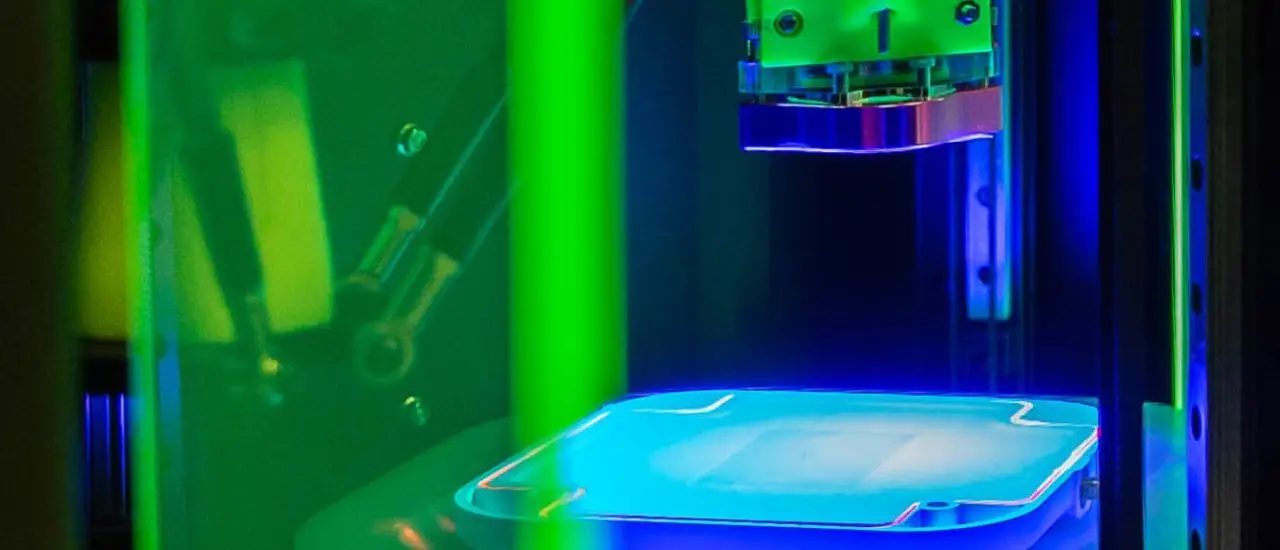

At the end of February 2025, a project based on battery-powered ultrasonic sensors from Pepperl+Fuchs was launched, in which digital level monitoring with LoRaWAN transmission monitors the quantities in the lubricant drums and automatically sends the data to a specially developed database. The real innovation is that the data is now transmitted via LoRaWAN.

Project launch after three months

baier & michels has been using Pepperl+Fuchs inductive sensors as standard for years. These are mainly used in process monitoring. A typical example: The sensors are attached to camshafts and deliver a signal with each revolution. In this way, the company monitors the cycle of the machines and triggers the timing of the entire process monitoring.

The move to integrate LoRaWAN sensors was therefore rather coincidental. During an on-site appointment, the appropriate sensors were installed directly in the production facility. A practical quick start. It took only three months from the initial contact to complete integration. A proof of concept was unnecessary because the quick start was convincing.

"The ideal situation is when a customer – like Maximilian Korte – has the courage to say: 'Let's just get started: buy a gateway for around €200 and launch the first project.' That doesn't always happen. That's why we have our demo case with us, which contains everything: gateway and sensors. This means that the customer has a small, functioning system in a short time. If the customer says, 'I like it, keep going,' we take the next step together with our partners: I take care of the sensor technology, the partners take care of the network—radio coverage, LoRaWAN server, everything that's needed," explains Daniel Möst, Technology Manager at Pepperl+Fuchs.

Integration into production

The topic of level monitoring is not new—the desire to continuously monitor conditions has existed for years. However, classic, wired technology comes with many challenges: numerous cables, high setup costs, and complex installation.

"We immediately recognized that the solution is straightforward and can be implemented without lengthy preparation. That also meant: without high costs," explains Maximilian Korte.

Daniel Möst also sees the on-site appointment as a breakthrough: "This personal moment is crucial, especially with new technologies. When an idea is not just discussed in theory but can be experienced in practice, doubts disappear. An initial idea turns into a tangible project, and hesitation turns into enthusiasm."

Immediate advantage

The mechanical integration was completed in minutes: the sensor with a 2-inch external thread could be screwed directly into the tank cap – without any reworking. Configuration via the Bluetooth app and the LoRaWAN connection were quick and easy.

Since the solution is wireless, neither a power supply nor data cables are necessary. Result: The sensor was productive in no time, and automatic fuel monitoring could start seamlessly.

Conclusion

baier & michels shows how digital tank monitoring can be achieved without complex cabling. The transition from manual visual inspection to lubricant level monitoring with LoRaWAN level sensors makes inventories transparent and predictable – and creates the basis for reliable delivery as production grows.

As the database grows, limit values can be refined, batch sizes optimized, and API connections to ERP or MES implemented for semi-automated orders.