- Encoded RFID labels are fundamental to automation, traceability, and reliable control of production and warehouse processes.

- PID 3SIXTY centralizes label management and real-time monitoring, simplifying ERP/MES integration and line configuration.

- Modular, side-mounted and end-of-line systems allow flexible placement across packaging, food, pharma, e‑commerce, and consumer goods lines.

- Features such as RFID encoding/verification, automatic format adjustment, and remote diagnostics increase availability and reduce downtime.

- Contactless application methods like tamp-blow enable precise labeling without mechanical contact, supporting high-throughput industrial environments.

PID 3SIXTY: Central Software Platform for Labeling and Process Control

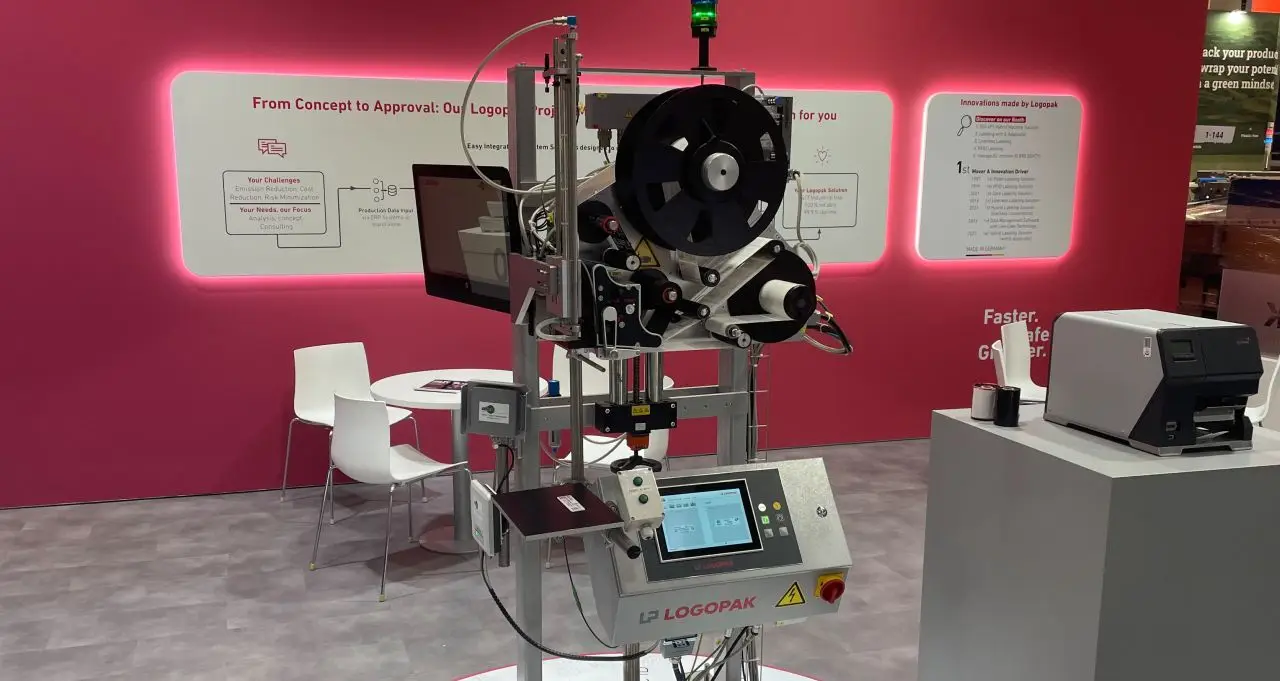

For over 25 years, Logopak has been a pioneer in RFID labeling systems, RFID label printing, and industrial marking technology. As one of the first suppliers of print & apply systems, the Schleswig-Holstein-based company worked with leading retail chains to develop RFID-based solutions for optimizing logistics and production processes at an early stage.

The global sales network is complemented by a worldwide service network—supported by Logopak. In an interview with Anja Van Bocxlaer Managing Director Steffan Gold explains how modern RFID labeling systems and RFID label printing work with the PID 3SIXTY software platform to support industrial production.

Why RFID Label Printing Matters in Production

How encoded labels unlock automation, traceability, and process reliability across modern manufacturing.

What role does marking technology play in industrial production?

Steffan Gold: Modern industrial production is no longer conceivable without labeling. Whether barcode or RFID technology – today, the identifier is the basis for automation, traceability, and process reliability. Without it, neither warehouse processes nor production processes can be reliably controlled. That is why our solutions are an indispensable part of every industrial manufacturing process.

From Print-and-Apply to RFID Label Printing: Logopak’s Path

Milestones from early barcode systems to RAIN RFID and software-driven label management

How did Logopak get into RFID labeling systems and industrial marking?

Steffan Gold: Logopak was founded in 1978 with the aim of developing special machines for the packaging industry. The company recognized the growing need for automated barcode labeling early on and pioneered the first print-and-apply systems on the market.

Initially, printers from the Swedish manufacturer Ecupan were used, but in 1989 Logopak decided to develop its own system, which was successfully launched in 1991.

Logopak presented its first RFID-based labeling systems as early as 1999. However, the breakthrough did not come until the advent of RAIN RFID around 2004, when demand for contactless identification in industry increased significantly.

Thanks to our roots in special-purpose machine construction, the focus from the outset was on robust, reliable, and technologically innovative solutions—both mechanically and in terms of software. These were supplemented by our own software, which enables easy integration into existing IT systems, as well as tools for layout design and remote maintenance.

Where RFID Label Printing Runs: End-of-Line to Logistics

Typical placements and industries—from packaging lines to warehouse processes in food, pharma, e-commerce, and more.

In which production processes are Logopak machines used?

Steffan Gold: Our systems are used wherever products, cartons, or pallets need to be marked reliably and usually in large quantities – i.e., classically at the end of production or packaging lines, or in downstream logistics processes.

This is a key step, especially in industries such as food & beverage, e-commerce, pharmaceuticals, and consumer goods, in order to make products traceable and comply with legal requirements, or to be able to identify and control them in logistics processes.

Modular RFID Label Printing on the Line

Side-mounted units and configurable modules that fit seamlessly into existing conveyors and production cells.

Can Logopak systems also be placed directly on production lines in a modular fashion?

Steffan Gold: Yes, of course. We can also supplement any production line with components that are installed on the side of the conveyor belt, for example. These units can then label – exactly as required. This means that our solutions are suitable for both large-format systems such as pallet labeling and smaller setups directly on the line.

RFID Label Printing: Functions from Data to Application

From IT data input to variable printing, RFID encoding/verification, and precise, contactless application.

What functions do the RFID labeling systems offer – from label printing to application?

Steffan Gold: Our labeling systems handle the entire labeling process fully automatically: from data input from the local IT system to variable label printing and precise and secure application.

We also cover special functions—for example, RFID labeling, barcode error checking, automatic format adjustment, and real-time system diagnostics. Our systems are compatible with RFID smart labels and enable contactless labeling for maximum efficiency—a central component of Industry 4.0-compatible production processes.

Advantages of RFID Label Printing in Existing Lines

High availability, easy maintenance, and flexible changeovers that reduce downtime and boost OEE.

What advantages do Logopak labeling systems offer over conventional labeling systems – especially when integrated into existing processes?

Steffan Gold: Logopak labeling systems offer clear advantages here. Our systems are modular in design, very robust, and can be seamlessly integrated into existing lines, both physically and in terms of IT. Many customers appreciate the high availability, easy maintenance, and above all the flexibility – for example, when changing products. This reduces downtime and ensures greater efficiency during operation.

In addition, we can respond to individual customer requirements and, if necessary, develop and build customized special solutions. One of our strengths is that we develop the systems entirely in-house and are free to decide whether we can help our customers by making adjustments to the mechanics, electronics, or software.

"When it comes to large quantities and industrial processes, Logopak is in its element. Whether pallet labelers or end-of-line solutions, our labeling systems stand for reliability and availability where it really counts."

PID 3SIXTY: Central Control for RFID Label Printing

Centralized setup, monitoring, and ERP/MES connectivity for end-to-end visibility and fewer stoppages.

What role does the PID 3SIXTY software platform play in the management and monitoring of RFID labeling systems?

Steffan Gold: PID 3SIXTY is our central platform for controlling and monitoring labeling. With the manage.ID module, data, layouts, and orders can be managed centrally, regardless of the manufacturer. A key feature is the simple configuration for different line processes. This makes IT integration of the systems very easy.

The monitor.ID module adds a powerful real-time monitoring function to the platform: It enables visual control of the current machine status, provides information on order progress, malfunctions, and downtime, and thus creates full transparency along the line.

Both software modules can be linked to ERP or MES systems, enabling end-to-end data management or monitoring – which helps to optimize processes and avoid downtime.

The platform also supports the management of RFID data, integration into RFID systems, and real-time monitoring of RFID-based labeling processes.

Curious?

Learn more about Logopak's RFID labeling solutions and the PID 3SIXTY software platform – directly at logopak.com or in a personal conversation with the experts at Logopak.

Glossary: What Is a Tamp-Blow Applicator?

A non-contact labeling method that places labels accurately using vacuum pick-up and a short burst of air.

A tamp-blow application—as used in the Logopak 410 TB RFID—is a labeling process in which the label is picked up by vacuum on a stamp (tamp pad). The stamp moves pneumatically to within a few millimeters of the product and blows the label onto the surface with a short burst of air. There is no mechanical contact between the pad and the product.