- The RFID proof of concept (Dec 2023–Feb 2024) achieved 99.99% inventory accuracy.

- Inventory time dropped from three days with 15 employees to one hour with a single employee.

- Beontag passive tags were selected as the most practical, cost-effective option after comparative testing.

- The solution integrates handheld UHF readers with a Microsoft Azure cloud platform for real-time encoding, counting, and search functions.

Refrigeration manufacturer and distributor Imbera Cooling produces 850,000 refrigerators a year. Since 2024, the company has been using RFID technology to more efficiently manage its warehouse in Colombia. After a successful proof-of-concept phase (December 2023 - February 2024), the results are impressive: 99.99% inventory accuracy - and an inventory process that previously took considerable time is now completed by a single employee in just one hour.

In collaboration with Ideas Control, a track and trace solution has been implemented that revolutionizes equipment and asset tracking - more efficient, more transparent and smarter.

The article is written by Think WIoT and is based on a presentation by Patricia Ramirez, Executive Director and Business Development Manager at Ideas Control, during the Think WIoT livestream on March 27, 2024.

Revolutionizing refrigerator tracking: Imbera Cooling adopts RFID!

Background: Digitalization in Colombia

Colombia has made significant progress in digitalization in recent years. According to the World Economic Forum, the internet usage rate increased from 38% in 2014 to 63% in 2024. However, challenges remain, particularly in rural areas, where only 16.2% of the population has internet access, compared to 63% in urban regions.

To bridge this digital divide, the Colombian government has launched initiatives such as the "Computadores para Educar" program, which establishes public Wi-Fi hotspots in community centers. The business landscape is dominated by micro and small enterprises, which make up 99.3% of all companies, while medium and large enterprises account for only 0.5% and 0.2%, respectively.

For small businesses in countries like Colombia, a lower number of hardware devices at the start of a project will generate greater traction and faster implementation.

Patricia Ramirez Granados - Executive Director

Patricia Ramirez has led the development of RFID and biometric solutions at Ideas Control since 2009 as Executive Director and Business Development Manager. She focuses on asset tracking, access control and time and attendance, from pedestrian and vehicle security solutions to RFID-based inventory management.

Together with her team, she is responsible for the development, implementation and maintenance of these technologies. Committed to making technology accessible to organizations of all sizes, she and her team work to develop, implement and maintain these solutions. In doing so, she facilitates their adoption and maximizes their impact across multiple industries.

Inventory marathon at Imbera Cooling: slow, costly, inefficient

Imbera Cooling struggled with a time-consuming and error-prone inventory management process in its Colombian warehouse. Every month, 3,000 refrigerators, freezers, and water dispensers arrived – but the inventory process was a major challenge:

3 days required for inventory counting

15 employees working continuously

Forklifts needed to reach shelves up to 20 meters high

Items stored on the upper shelves had to be manually removed for counting, while the paper-based recording of serial numbers increased the risk of errors. The lack of real-time data made quick decisions difficult and delayed order processing – a major obstacle to operational efficiency.

RFID as a game changer: automated inventory management at Imbera Cooling

To end the inefficient inventory marathon, Imbera Cooling adopted an RFID track-and-trace solution. In collaboration with RFID system provider Ideas Control, the company developed a solution that minimizes manual processes, provides real-time data, and drastically improves inventory accuracy.

The technology is particularly valuable since Imbera Cooling distributes refrigerators on a rental basis across the country. In December 2023, the company launched a proof of concept to test various RFID tags and determine the best solution for seamless integration.

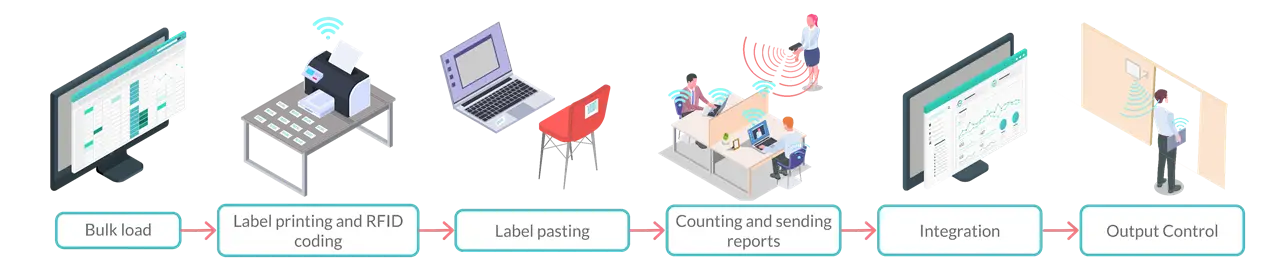

Solution at a glance

Cloud-based platform for real-time data

RFID encoding & inventory counting in seconds

Device search at the push of a button instead of tedious forklift searches

Export functions for Excel and PDF reports

Selecting the right RFID tags

Choosing the appropriate RFID tag was a crucial aspect of Imbera Cooling's proof of concept, conducted in collaboration with Ideas Control. The company needed a cost-effective passive tag that would enable inventory tracking from the warehouse without requiring physical movement of the devices.

Optimal RFID Tag Choice: Beontag Wins at Imbera Cooling

The selection of the right RFID tag was a critical factor in the proof of concept by Imbera Cooling and Ideas Control. The company needed a cost-effective, passive tag that would enable inventory tracking without physically moving the devices.

Three tag types were tested:

Ceramic tags from Oppiot (70x20 mm)

Metal tags from Zebra Technologies (60x25 mm)

Non-metallic paper tags from Beontag (46x20 mm)

Tests were conducted with 25 tags of each type, evaluating readability, adhesion, and encoding on multiple shelving levels. All variants provided reliable results, proving suitable for inventory counting and device searching.

While ceramic and metal tags were highly durable, they were too expensive. The paper tag from Beontag was cost-effective but posed challenges on metallic surfaces. The solution: placing the Beontag tag inside the glass door at the bottom of each unit and on the outer packaging. This made Beontag the most practical and economical choice for Imbera Cooling's RFID-based inventory system.

Efficient encoding, counting, and searching

After selecting the optimal RFID tag, Imbera Cooling moved to the next phase of the proof of concept: optimizing encoding, counting, searching, and transmission processes.

The solution used a Chafon UHF RFID handheld reader (CF-U909) with:

Fast reading speed

Bluetooth 4.0 connectivity

Circularly polarized 3-dBi antenna

Impinj R2000 technology for precise scanning

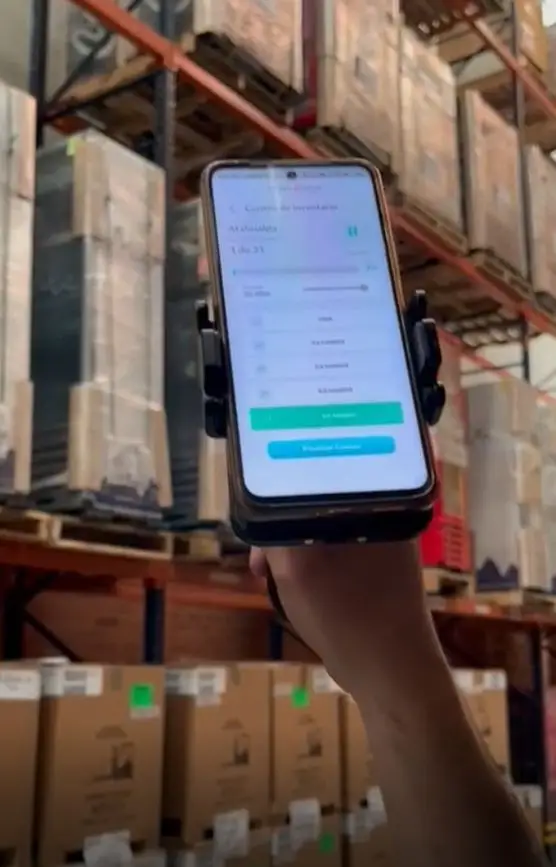

The system, controlled via a cloud platform on Microsoft Azure, operates through web and mobile interfaces. Employees could manage the entire RFID process once a smartphone was connected to the handheld reader.

Low power for precise encoding

High power for fast reading and searching

During the encoding phase, barcodes were scanned, serial numbers recorded, and photos of the devices captured. Employees could walk through the warehouse with the handheld scanner, effortlessly reading tags on three levels. Proper device positioning was crucial – doors had to face forward.

The software, tested for user-friendliness, supported all essential workflows: loading items, encoding, counting, and searching. Over time, additional data fields were integrated, such as manufacturer details. The output process was also optimized – now, a photo and the driver’s signature document the handover, ensuring accountability in deliveries.

Successful implementation: faster inventory, higher accuracy, and future plans

The proof-of-concept phase, completed in February 2024, led to significant improvements in Imbera Cooling's inventory management.

Inventory time reduced from 3 days (15 employees) to 1 hour (1 employee)

99.99% inventory accuracy

No need to physically move devices for serial number verification

As a result, other Imbera locations are adopting the solution, with the company highly satisfied. Inventory tracking and searching have significantly improved. Future plans include expanding real-time inventory management, automating tracking, and fully digitizing inventory records to increase efficiency and reduce costs.

Next project phases will focus on maintenance and repair warehouses. Imbera Cooling is also exploring IoT integration for GPS tracking and motor temperature monitoring, as well as additional features like driver photos and vehicle details to further enhance accountability in device deliveries.

We are now implementing this RFID track-and-trace solution in other Imbera Cooling locations as well. They are very satisfied with the solution.

Patricia Ramirez Granados - Executive Director

About Ideas Control: RFID expert with over 50 years of experience

Ideas Control is a pioneer in technological solutions and a leading provider of RFID systems and solutions. With over 50 years of experience in RFID technology, the company has established a strong market position and now serves more than 1,000 customers in Colombia and Central America.

The headquarters of Ideas Control is located in Colombia, while branches in the USA and Canada strengthen the company’s international presence. With innovative solutions and a deep understanding of RFID applications, Ideas Control helps businesses optimize their processes and digitize their inventory management.

About Imbera Cooling: a pioneer in refrigeration technology

Imbera is a globally leading company in the commercial refrigeration industry, specializing in the development, design, and manufacturing of refrigeration equipment and components for the beverage and food industry since 1987.

With five production facilities in Brazil, Colombia, Mexico, Argentina, and South Africa, as well as sales offices in 17 countries and more than 5,000 employees worldwide, Imbera exports its products to over 60 countries.