Key takeaways

- Enables fast, contactless bulk detection on conveyor belts

- Includes pre-installed TVSnode software with REST API

- Operates under conveyor speeds below 1 m/s

- Rugged metal housing with IP67 protection

- Supports ISO 18000-63 and EPCglobal Gen 2 protocols

Talk to the product expert

Hendrik Schnabel, Product Manager RFID UHF Systems

Detailed product information

Reliable bulk RFID detection on conveyor lines

This UHF RFID tunnel solution creates a clearly defined read zone for automated, contactless identification of tagged items moving on conveyor belts. Built for efficient intralogistics workflows, it enables fast in-motion detection to support traceability and process transparency.

With pre-installed TVSnode software and Ethernet connectivity, integration into higher-level IT/OT systems is straightforward via TCP/IP and an integrated REST API.

Key Facts

UHF RFID tunnel solution for (bulk) detection of objects on conveyor belts

Pre-installed TVSnode software; communication via integrated REST API

Max. conveyor speed: < 1 m/s

Recommended distance between objects: > 1.3 m

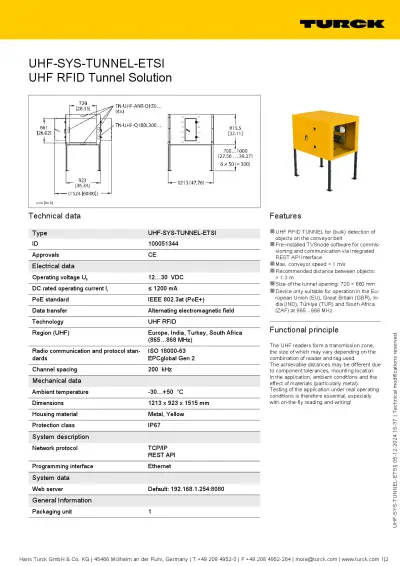

Tunnel opening: 720 × 660 mm

Frequency range: 865…868 MHz (EU/India/Türkiye/South Africa region)

Protocols: ISO 18000-63 / EPCglobal Gen 2

Supply: 12…30 VDC (≤ 1200 mA) or PoE+ (IEEE 802.3at)

Rugged design: metal housing, IP67

Temperature range: -30…+50 °C

Dimensions: 1213 × 923 × 1515 mm

Applications

Automatic identification and counting of totes, cartons, trays, or mixed item flows on conveyor lines

Goods-in / goods-out verification, shipping checks, and loading confirmation

Sorting and buffering zones in warehouses and distribution centers

Track & trace and process monitoring for intralogistics material flows

Use cases requiring repeatable in-motion reads (real-world validation recommended, especially near metal)

Turck UHF RFID Tunnel Datasheet

PDF, 1.53 MB

Product Images