The key to total supply chain control? A digital twin.

Today’s supply chains are under immense pressure to be more transparent, sustainable and efficient. With rising demands around traceability, compliance and operational control, businesses need smarter tools to stay ahead. The answer isn't more spreadsheets, it's smarter technology.

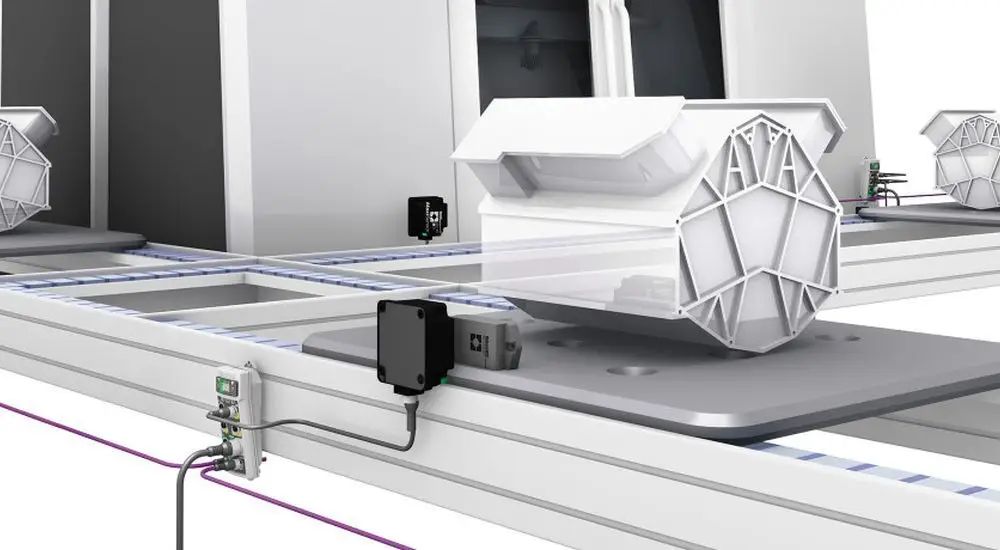

At Connected Load Carrier, we believe the most future-proof solution is digital twin technology. We transform passive physical assets, like pallets, crates and roll cages, into intelligent, data-driven parts of your supply chain. We create a real-time virtual replica of these assets, providing you with a single source of truth for their location, condition and usage.

What is a Digital Twin?

A digital twin is a dynamic digital replica of a physical object or system that uses real-time data to mirror and simulate its real-world counterpart. In the context of logistics, a digital twin doesn't just mirror an asset's physical characteristics; it evolves with it. Through real-time data captured from IoT sensors, a digital twin reflects the asset's current state, behavior and entire lifecycle; from production to recycling.

This capability is crucial for efficiently handling complex, distributed supply chain networks. It allows you to oversee and manage assets and operations from any location, giving you a level of control that was previously impossible.

Why is it relevant today?

Today’s supply chains are under a lot of pressure. You’re being asked to meet sustainability targets, reduce costs, increase transparency and prepare for new regulations like the Digital Product Passport (DPP). All this while running leaner and faster than ever before.

For companies looking to automate and scale their compliance efforts, digital twin technology combined with robust IoT infrastructure offers the most operationally beneficial path. Leading companies are already turning to this technology to ensure their supply chains are flexible, agile and responsive enough to overcome unexpected disruptions.

Our approach at Connected Load Carrier

At Connected Load Carrier, we leverage digital twin technology to transform supply chain operations. With our solution, each asset gains a unique digital identity, connected to real-time sensor data and fully manageable through one intuitive platform: the 360° Asset Control Tower.

Within this platform, you can track an asset's condition, usage and location. You can also share selected data with stakeholders via scannable QR codes. It’s everything you need to turn physical assets into active sources of operational insight.

Digital twins aren’t just the next big step in asset management; they’re the foundation for a smarter, more sustainable, and more transparent supply chain. Whether your priority is achieving DPP readiness, minimizing waste, or gaining valuable visibility without relying on outdated spreadsheets, we provide the tools and support to help you move forward with confidence.

Want to learn more?

For a deep dive into the technology behind our solution and a full list of benefits, read our dedicated blog post: Digital Twin Technology In Your Supply Chain.