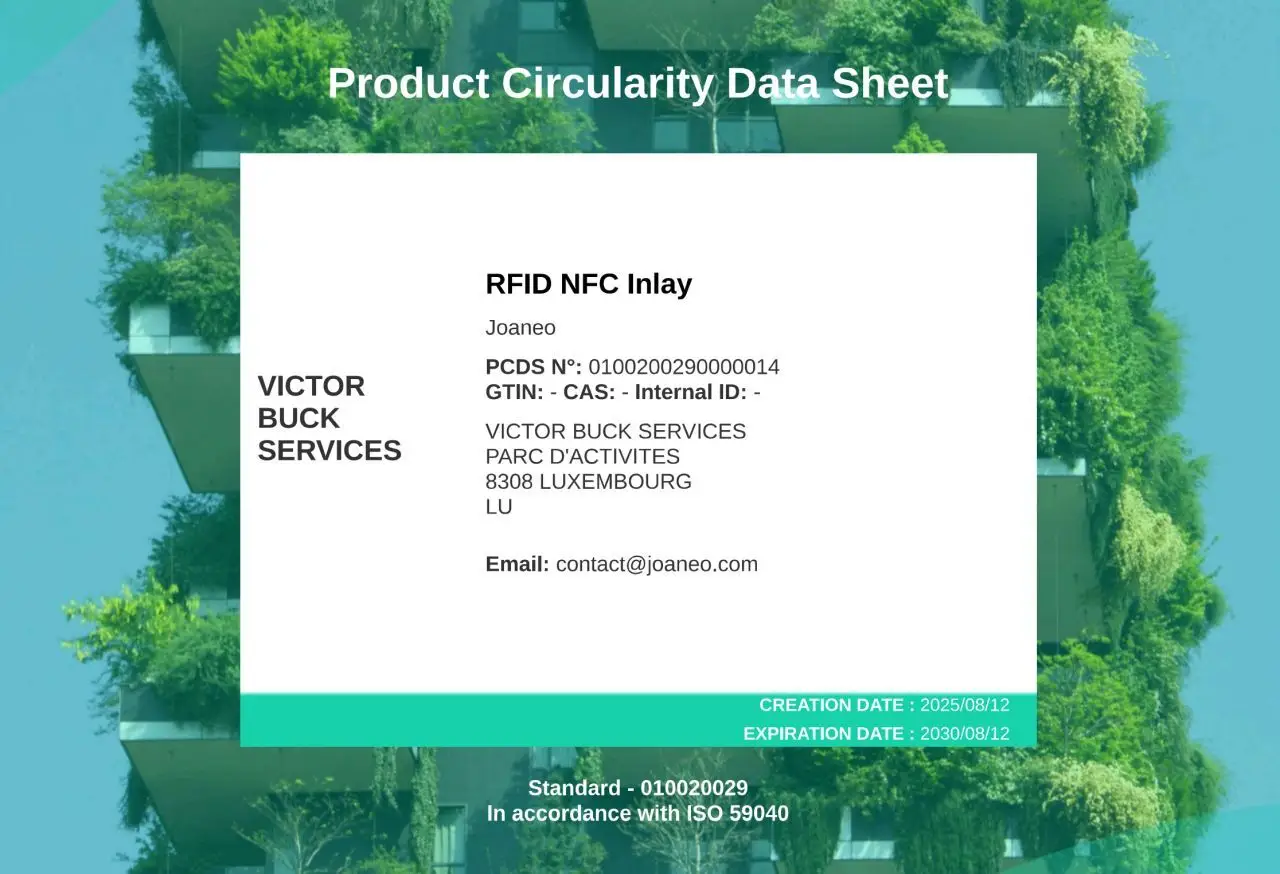

- Joaneo applied the ISO 59040 standard to create a Product Circularity Data Sheet (PCDS) for the V-TAG 36 paper-based inlay.

- The analysis shows 75–95% of inlay materials can be recycled and silver ink can be recovered without loss of quality.

- The PCDS provides standardized, auditable data that supports readiness for the Digital Product Passport under EU Regulation 2024/178.

- Joaneo will update the PCDS regularly, extend it to other inlay types, and collaborate with Terra Matters on certification and verification processes.

Joaneo has conducted a study to evaluate the circular economy of inlays. Analyzing such complex systems is challenging, but the company has taken on this task driven by conviction and a commitment to quality. The study follows an internationally recognized methodology in accordance with ISO 59040, enabling a transparent assessment of circularity throughout the entire life cycle—from manufacturing to end-of-life.

In an interview with Anja Van Bocxlaer, Joachim Priem, Business Developer Printed Electronics at Victor Buck Services, and Dr. Syaiful Mohd, RFID Field Engineer at Joaneo explain why analyzing recyclability gives Joaneo's products a decisive advantage.

Joaneo relies on ISO 59040 and PCDS for circular economy and regulatory security

Numerous companies publish data on the circular economy. However, without a binding standard, reliability is often lacking – with the risk of greenwashing and a lack of trust.

With this analysis, Joaneo demonstrates that the company is taking the lead in preparing for the requirements of the Digital Product Passport, which is based on the Regulation (EU) 2024/178. Joaneo thus sends a clear signal about its intent to comply at an early stage.

In collaboration with the Luxembourg-based organisation Terra Matters, Joaneo has also created its first Product Circularity Data Sheet (PCDS). This enables Joaneo to provide trustworthy information and provide binding proof of the circularity of its inlays.

The analysis was carried out on the new V-TAG 36 NFC inlay. As this tag is paper-based, the results apply to all of the company's paper-based inlays.

What specific reasons led you to launch the circular economy analysis of your inlays?

Joachim Priem: Sustainability is firmly anchored at Joaneo – as it is at Victor Buck Services and the POST Group Luxembourg. With our strategic decision to focus on paper-based inlays and an environmentally friendly production process, we have made sustainability one of our key priorities.

At the same time, we are aware that greenwashing and different "green certificates" lead to confusion in many industries. That is why we wanted to have our paper-based inlays evaluated according to an international standard – specifically in terms of environmental compatibility and recyclability compared to conventional RFID inlays.

With billions of RFID tags in use on products worldwide, it is essential from an ESG (Environmental Social Governance) and circular economy perspective to also consider RFID tags at the end of their life cycle from a sustainability perspective.

ESG is a core value of our company. Our parent company, POST Group Luxembourg, has been voluntarily publishing ESG reports already for years. We regularly measure our carbon footprint and work every day to reduce the environmental and social impact of our business activities.

How do your customers view this decision?

Joachim Priem: Very positively. Existing and new customers were asking for concrete proof of sustainability. This includes ruling out animal testing, ensuring that our products do not contain any hazardous substances, and having a recycling certificate. Label- and packaging manufacturers who produce cardboard and paper-based packaging can easily recycle our inlays using existing processes. This is a major advantage and will become even more important in the future, as the Digital Product Passport sets requirements for recyclability.

With the circular economy analysis, we can provide our customers with clear and reliable information about the environmental impact of our products, their bill of materials, their longevity, and their traceability.

Why did Joaneo choose the ISO 59040 standard?

Joachim Priem: ISO 59040:2025 is a new initiative. It has only been around since February 2025. It aims to standardize data on circular products and thereby create more transparency. It is part of the ISO 59000 family of standards on circular economy, which defines terminology, principles, and guidelines for implementation.

The standard provides clear, verifiable, and standardized information on how a product is designed and manufactured, taking into account its entire life cycle. It includes a document template and a framework for creating Product Circularity Datasheets (PCDS), which were developed by Terra Matters in accordance with ISO 59040.

This makes analysis and reporting much easier for companies—there was no comparable standard before. This is precisely why we opted for this standard. Until now, the analysis has been carried out internally, but it will be audited in the future. An official certification program is currently being prepared.

ISO 59040 was actually initiated by the Luxembourg government. It is a tool for the global need for clear, transparent, and standardized information on the circular economy. However, the standard is not purely a Luxembourg initiative, but an international one—and at the same time the first ISO standard to originate from Luxembourg. Joaneo is one of the first companies to have implemented it and our V-TAG 36 inlay is the very first RFID inlay that comes with an ISO59040 PCDS.

How was the analysis carried out in concrete terms? Which life cycle phases were taken into account?

Joachim Priem: First of all, I would like to explain that the PCDS covers all phases of a product's life cycle. This is the only way to provide a consistent and complete statement on the structured exchange of data for the circular economy. It starts with the materials used, continues with design and manufacturing, and ends with use and end-of-life. Specifically, aspects such as material use, recyclable production, durability and extended service life, recyclability at the end of the product's useful life, and the resulting benefits are considered.

In our product analysis, we have taken these requirements into account and considered, among other things, the procurement of paper and ink, the possible use of hazardous substances, the energy sources used during production, the entire manufacturing process, and the recyclability and reusability of our inlays.

What were the most important findings of the analysis?

Joachim Priem: The results of the analysis were very positive overall. There were no surprises or critical issues – rather, the study confirmed that we are on the right track with our inlays in terms of material use, environmental compatibility, and recyclability.

When it comes to the use of materials, we have focused on sustainable solutions from the very beginning. Our base material is paper from responsibly managed forests that is globally PEFC-certified. The silver ink we use also complies with RoHS requirements and does not contain any hazardous substances.

Another important point concerns the energy supply for our production. All Joaneo offices and production facilities operate with regional green electricity from solar, wind, and hydro power as well as biomass, supplied by Nova Naturstroum (Enovos). For us, this is a decisive contribution to the circular economy right from the manufacturing stage.

The end of the product's useful life was particularly interesting. Our inlays are designed to be completely recyclable. Between 75 and 95 percent of the materials can be recycled without any loss of quality. The silver ink particles can even be recovered unchanged and reused. The paper can be processed into recycled paper – and that in a market with a well-developed infrastructure. According to the European Paper Recycling Council (2024), 75 percent of paper is already recycled in Europe – a clear advantage for our products.

We have also considered factors that are not directly part of the PCDS but play a role in sustainability. Our additive printing process does not require chemicals or etching—the ink is only applied where it is needed. We also source locally from European partners and suppliers to further reduce the carbon footprint of our inlays.

RFID inlays have become a low-cost mass commodity product. Their total cost of ownership and ROI is often calculated without considering their impact on the environment in a circular economy. We want to address this important aspect by offering an alternative that contributes to ESG responsibility.

Were there any critical findings?

Joachim Priem: No, there were no critical results, but the study did reveal some issues. An important finding from the analysis for us was the recyclability of our silver-printed inlays on a PEFC-certified paper carrier. Although many products are recyclable in principle, their components often cannot be extracted in such a way that they can be reused for the same purpose. Instead, they are often downgraded to lower quality grades or used in products that are themselves difficult to recycle. A typical example is shredded PET bottles, which end up in mixed plastic furniture or insulation foams.

Within the PCDS (and ISO 59000 family), "recyclable" means that a product can be returned to new processes or products at the end of its life through activities aimed at recovering reusable resources – with the exception of energy recovery. This includes steps such as recovery, collection, transport, sorting, cleaning, and reprocessing. Recycling must be clearly distinguished from reuse.

A major advantage is that the silver particles in our RFID antennas can actually be extracted and recovered during the recycling process. All residues from our printing production—i.e., excess silver ink—can also be recovered without any loss of quality of the precious metal (Ag) and reused for the same purpose.

Dr. Syaiful Mohd - RFID Field Engineer, Joaneo

Will Joaneo continue to expand the study?

Joachim Priem: We will update the study regularly. If any information is missing or incomplete, the document can be expanded at any time. We also want to extend the PCDS to other products. This will then apply to other paper inlays, PET inlays, and inlays based on synthetic paper. Our two newpaper-based UHF inlays, which will be launched in September 2025, will also each receive their own PCDS.

Now the study will be distributed to the media and communicated to all customers, right?

Joachim Priem: We are currently disseminating the results, deliberately focusing on different target groups.

For our customers, transparency of information is key. They need to be able to understand which recycling processes are actually feasible – so they can make an informed decision when purchasing our products.

In our partner network, the focus is on opportunities for cooperation. The aim here is to work together on solutions and continuously improve recyclable product design.

Finally, there is the general public as a third target group. Here, we want to raise awareness of responsible consumption and show that high-technology products can also be recyclable and sustainable.

Terra Matters and ISO 59040

Terra Matters was launched in 2022 on the initiative of the Luxembourg government by the Luxembourg Ministry of the Economy and the Chamber of Commerce.

With the publication of the PCDS under ISO 59040, as from 02-2025 the organization interpret the ISO norm in a practical way and translate it into an understandable, compliant tool for global adoption.

The standard is intended to be understandable and accessible to all companies, including SMEs. Terra Matters provides support in understanding and implementing the necessary measures for compliance.

Development of a Product Circularity Data Sheet (PCDS) template and an online tool that enables every company to create its own PCDS.

Terra Matters is working with certification bodies to develop an official certification program. In the future, PCDS will be able to be verified, evidence requested, and an official "stamp" applied.

In the future, the platform could also be expanded for buyers who want to request and compare PCDS from their suppliers to simplify procurement.

Products without data become waste. Sharing simple, standardised data via the PCDS can help companies shed light on their products' circular properties in a world where sustainability is more and more needed and scrutinised.

Carole HENRY - Business Development Manager at Terra Matters