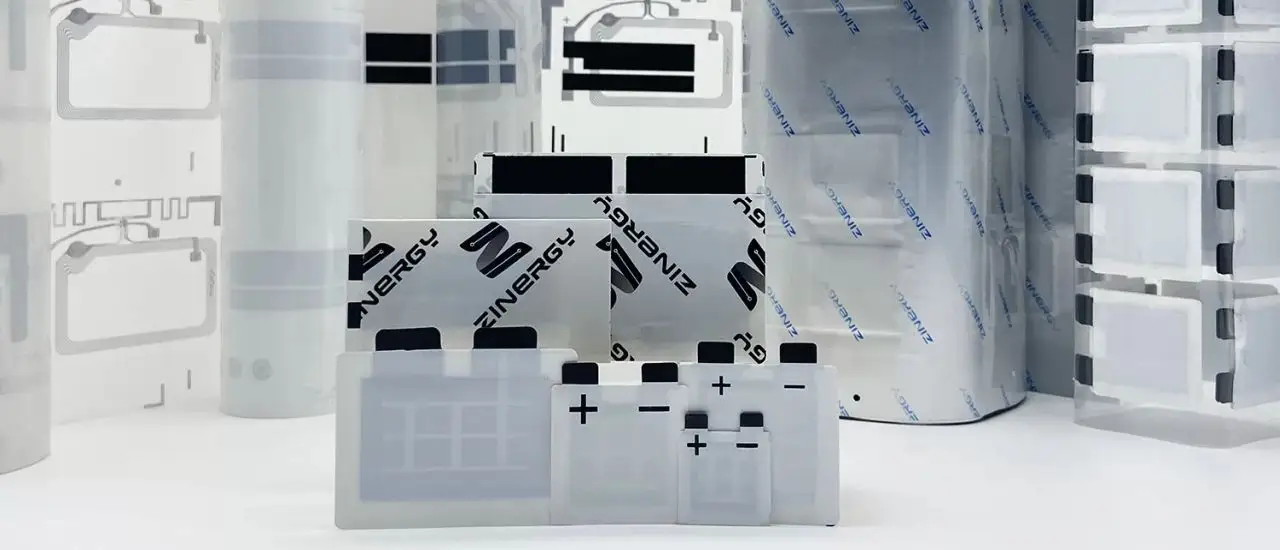

- Zinergy produces ultra-thin (≈0.5 mm), flexible printed zinc batteries designed for direct integration onto varied substrates.

- Zinc-based, water‑based chemistry eliminates lithium-related fire risk and is classified as non-dangerous for transport.

- Manufacturing is centralized in a high-capacity Shenzhen facility while R&D remains in Cambridge.

- Zinc offers lower raw-material cost and greater availability than lithium, aiding sustainability and supply-chain resilience.

- Roll-to-roll continuous production and growing demand are expected to drive significant unit-cost reductions over time.

Zinergy UK Ltd was founded in Cambridge in 2015 as a spin-off by a team from the University of Cambridge. From the outset, Zinergy has focused on developing and manufacturing printed batteries. The company produces zinc batteries that are safe, flexible, and ultra-thin, making them easy to integrate into or apply onto a wide variety of shapes and substrates, including skin.

Zinergy’s production is currently based in China, at its site in Shenzhen. There, the company operates a modern 5,000 m² production facility capable of producing millions of cells each month. Research and development remains at the company’s founding location in Cambridge, UK.

Dr. Andrew Matthews is Director of Business Development and responsible for business and market development in the USA and Europe at Zinergy. In this interview, he explains the properties and potential of printed batteries.

As flexible as a label and as powerful as a battery

The interview quickly makes it clear that printed, flexible batteries may sound simple at first but are in fact a highly innovative field of technology.

Unlike conventional batteries, which are rigid and often bulky, printed batteries must adapt precisely to the surface of objects. This places unique demands on both chemistry and manufacturing processes to ensure the batteries maintain their electrical performance even after being bent thousands of times. This is a test Zinergy routinely performs on its products.

Printed batteries are ultra-thin, down to 0.5 millimetres, and therefore extremely flexible, about as thick as a smart label or a medical plaster.

Andrew Matthews - Director of Business Development

Material advantage: Zinc (Zn)

Printed, flexible batteries also offer clear advantages in terms of materials. They are based on zinc, not lithium. Like cobalt and rare earths, lithium is a critical resource. These resources are limited in supply yet indispensable for some products, which makes them expensive. Batteries made from zinc do not require any critical resources. Zinc is inexpensive and readily available worldwide, making mass production efficient and economically attractive.

Furthermore, unlike lithium batteries, printed zinc batteries have a water-based chemistry and carry no risk of self-igniting, even when damaged or short-circuited. The IATA therefore classifies them as non-dangerous goods, safe to transport, which makes them ideal for logistics applications, including air freight where safety is critical.

The use of zinc is also a real plus in terms of sustainability: zinc batteries are easy to recycle and already meet the requirements increasingly placed on new technologies under the European Green Deal.

Zinc (Group 12, Period 4 in the Periodic Table according to Mendeleev) offers stable, water-based chemistry, uses abundant non-critical materials, and is fully recyclable, making it a safer and more sustainable choice.

Andrew Matthews - Director of Business Development

Zinc and lithium in comparison

There are many factors in favour of zinc. Compared to lithium, the market price is five to seven times lower, providing a significant economic advantage.

In addition, zinc is much more widely available worldwide and can be extracted more easily and in a more environmentally friendly manner. It is also less vulnerable to trade disruptions linked to political decisions.

Lithium, on the other hand, is considered a critical raw material because it is indispensable for electric cars, smartphones, and stationary energy storage systems, while being available only in limited quantities. For applications such as asset tracking and sensor data logging, zinc-based batteries are therefore a sound technological and ecological choice.

Costs are a question of quantity

Printed batteries are emerging as the power source of the future for the next generation of smart devices.

Andrew Matthews - Director of Business Development

In the past, they have been more expensive than conventional zinc button cells or AAA batteries, which use very similar chemistry. This is mainly because manufacturing batteries with standardised dimensions allows them to be produced in billions of units with optimised processes and bulk material purchasing. Printed batteries, by contrast, do not have standardised dimensions and the market is still relatively small.

As demand grows, costs will inevitably come down, and roll-to-roll printing is ultimately expected to offer even lower costs than conventional steel-cased batteries.

Interview with Dr. Andrew Matthews

Andrew, would you say that your batteries have disruptive potential?

Yes, absolutely. Their extreme thinness and flexibility make it possible to print the battery directly onto surfaces, a clear advantage over conventional batteries. Classic battery technologies do not allow such seamless integration. This is precisely where the disruptive potential of our solution lies.

Zinergy has had Chinese investors since 2018. How did that come about?

With a little bit of serendipity. While the world is changing now, traditionally, manufacturing operations have been viewed more positively in the East than in the West. This, combined with the fact that the initial investor was a former fellow Cambridge engineer who shared our vision, made it a natural fit.

The combination of cost-effective manufacturing, low unit costs, and high environmental compatibility makes our battery technology a sustainable solution with great potential. Our investors see it that way too. This also led to the establishment of our facilities in Shenzhen, which has allowed rapid expansion in production performance and capability. We already have one of the world's largest production capacities for printed batteries.

What role does manufacturing technology play in scaling up your battery production?

The process of producing these cells is not conventional. As a result, manufacturing technology and the ability to make developments and improvements quickly are key. When it comes to the cost-efficient production of integrated labels, roll-to-roll manufacturing is fundamental. This involves producing the entire label in a continuous process, and that is exactly what we are working on with our label partners.

At present, many circuits are still manufactured separately, often on polyimide or even classic printed circuit boards. Although our battery can be printed directly onto such substrates, the crucial step is integration into a fully continuous manufacturing process.

This is precisely the direction we are moving in: towards a continuous roll-to-roll approach for the entire label. This will enable significantly lower costs to be achieved.

Andrew Matthews - Director of Business Development